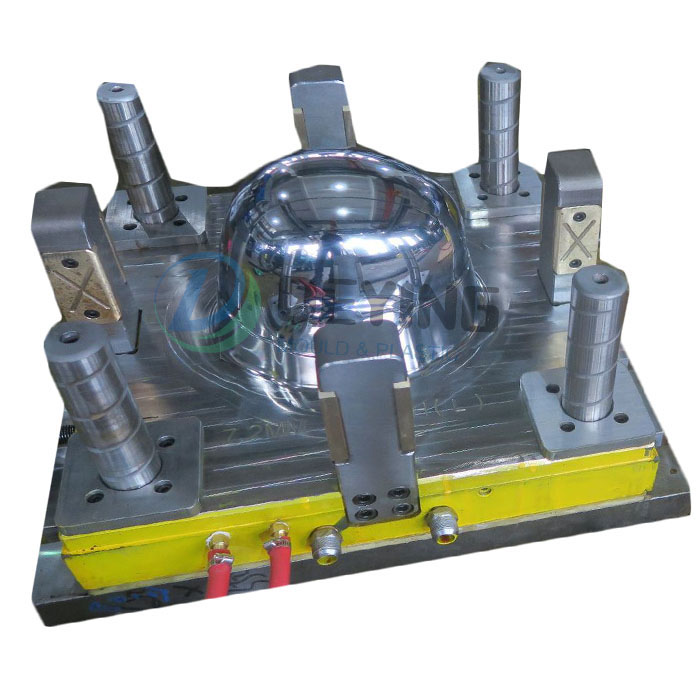

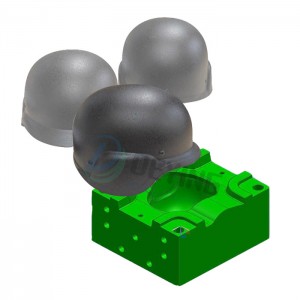

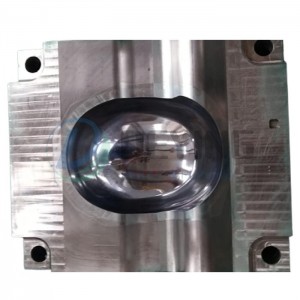

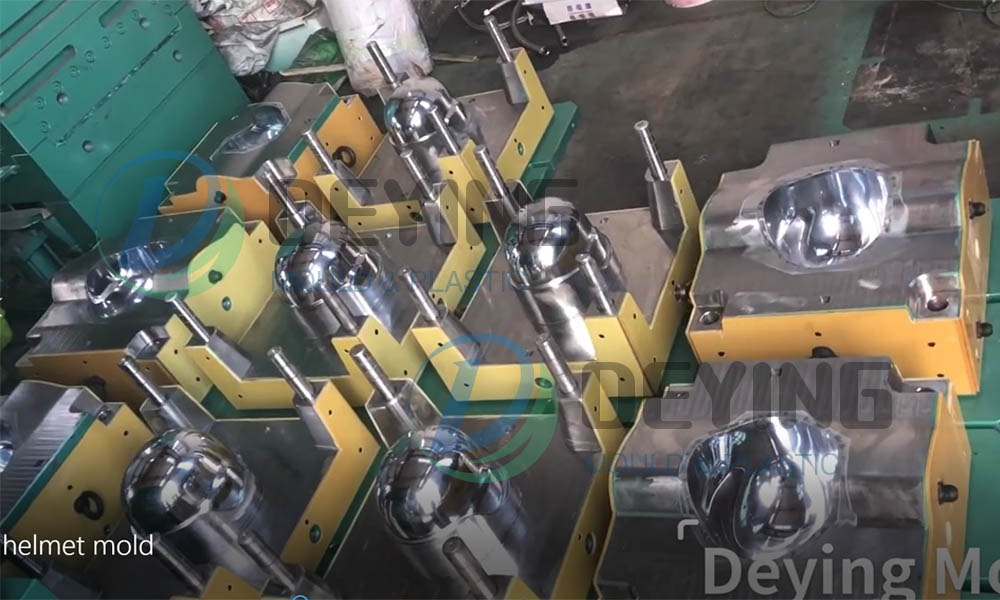

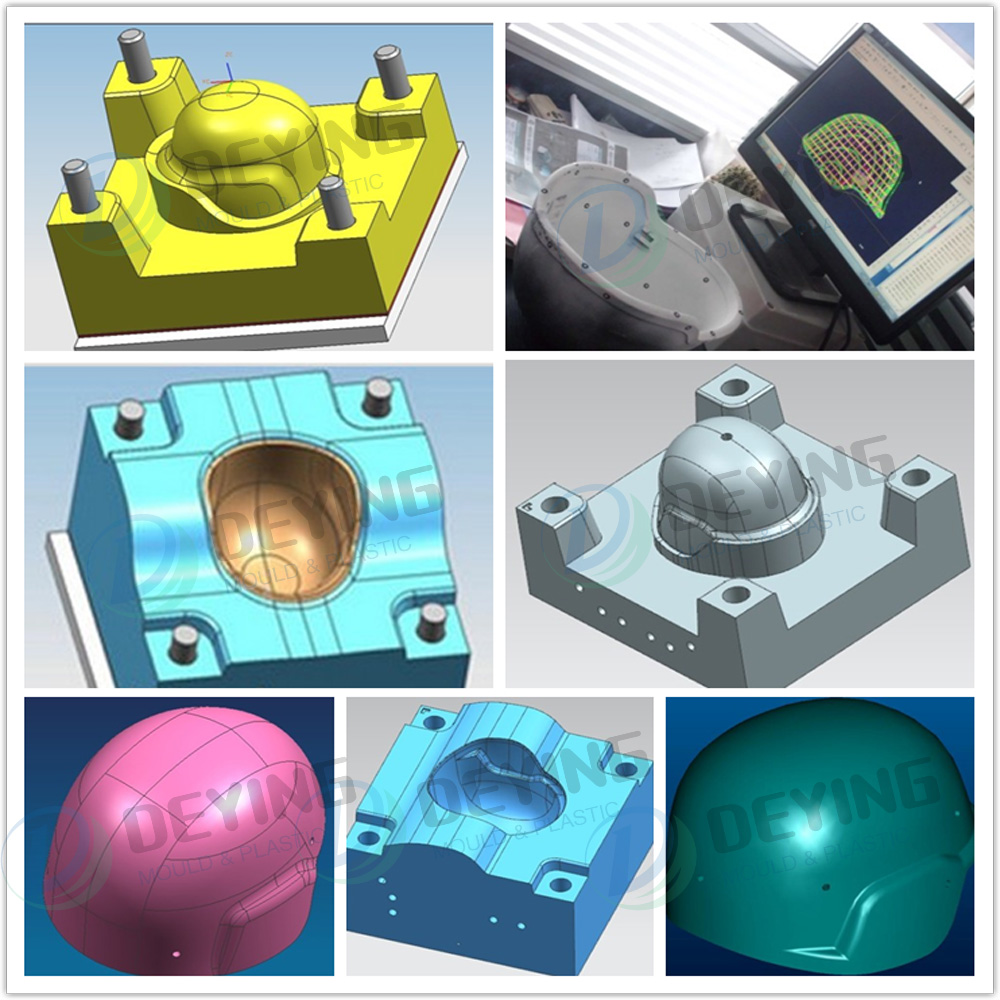

DIY custom ACH ballistic helmet moulding company supplying all kinds of model army helmet mold,such as FAST MICH PASGT helmet and Fiber glass SMC helmet molds

We are chinese professional and earliest mould manufacture for army products mold,bullet-proof helmet mold,anti-bullet armor plate molds.

China Helmets Mould suppliers - export from verified top China Aramid tactical fast Helmets moulds

UD/KEVLAR product mould

UHMWPE is commonly known as very high molecular weight polyethylene. Its molecular weight can reach 1 to 5 million. It has high wear resistance, low friction coefficient, high impact resistance, and better sound-absorbing performance. Compared with ordinary thermoplastics, it has lower fluidity and is difficult to process. At present, it can only be produced by molding. Our company cooperated with the *** unit to use its good impact resistance to develop body armor and bulletproof helmet molds, realize segmented pressurization and heating on a pair of molds, and switch the heating mold to cooling in the later stage of molding. The mold ensures that the product is cooled and shaped to the set temperature and set material hardness, ensuring that the product can be easily taken out of the mold.

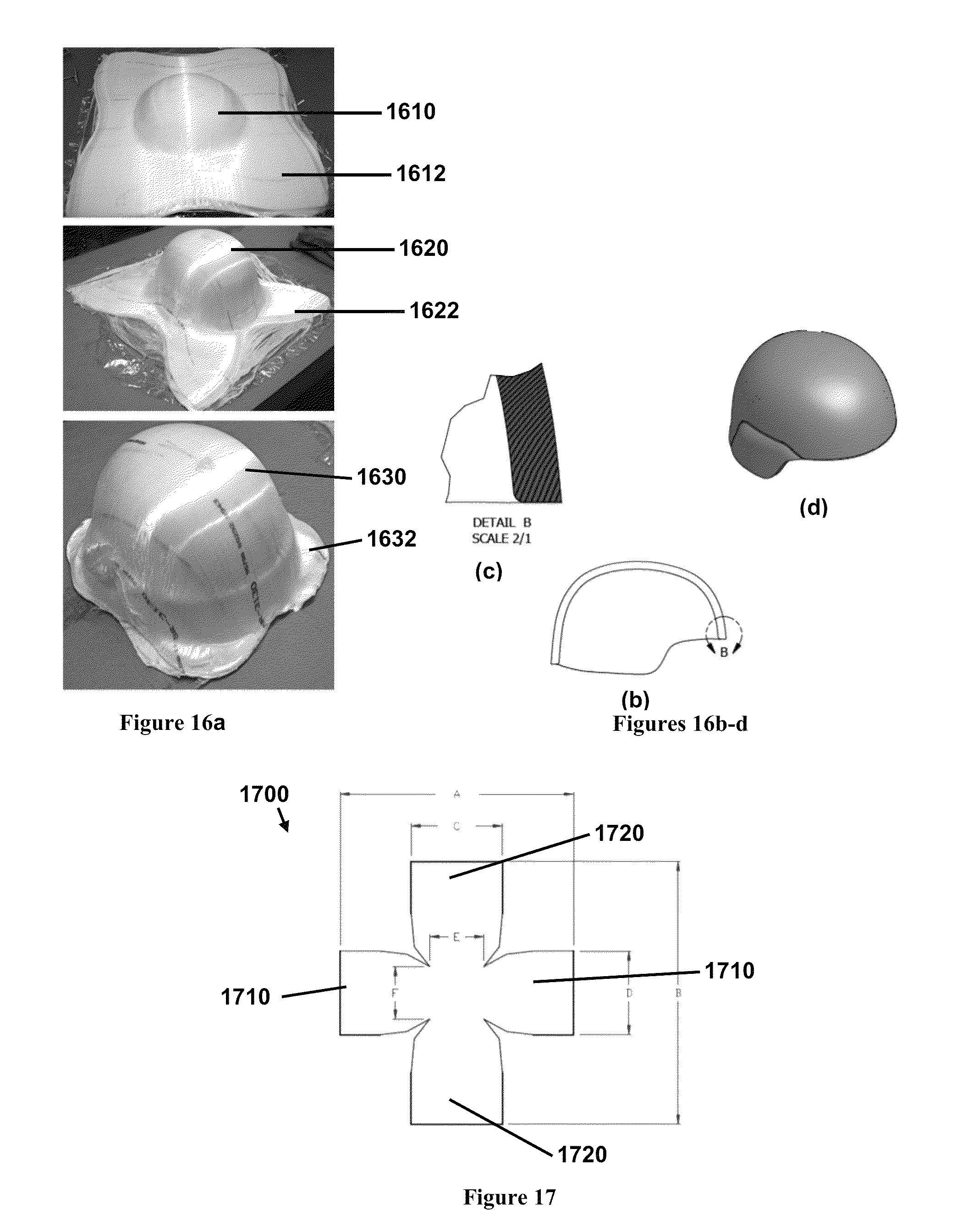

The full name of aramid is "poly-p-phenylene terephthalamide", and the English name is Aramid fiber (DuPont’s trade name is Kevlar). It is a new type of high-tech synthetic fiber with a very high degree of high modulus and resistance. High temperature, acid and alkali resistance, light weight and other excellent properties, its strength is 5-6 times that of steel wire, its modulus is 2 to 3 times that of steel wire or glass fiber, its toughness is twice that of steel wire, and its weight is only 1/ of steel wire. Around 5, it does not decompose or melt at a temperature of 560 degrees. It has good insulation and anti-aging properties, and has a long life cycle.

Due to the very high degree and very high modulus of aramid, at present, the bulletproof vests and bulletproof helmets of developed countries such as the United States and Britain are made of aramid. The lightweight of the aramid body armor and the helmet effectively improves the army's rapid reaction capability and lethality. During the Gulf War, U.S. and French aircraft used a large number of aramid composite materials. So far, aramid is one of the better materials for bulletproof soft helmets and bulletproof chest inserts.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com