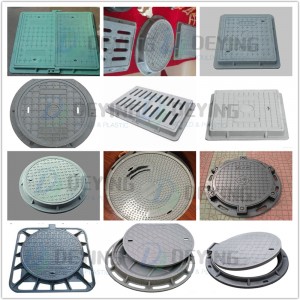

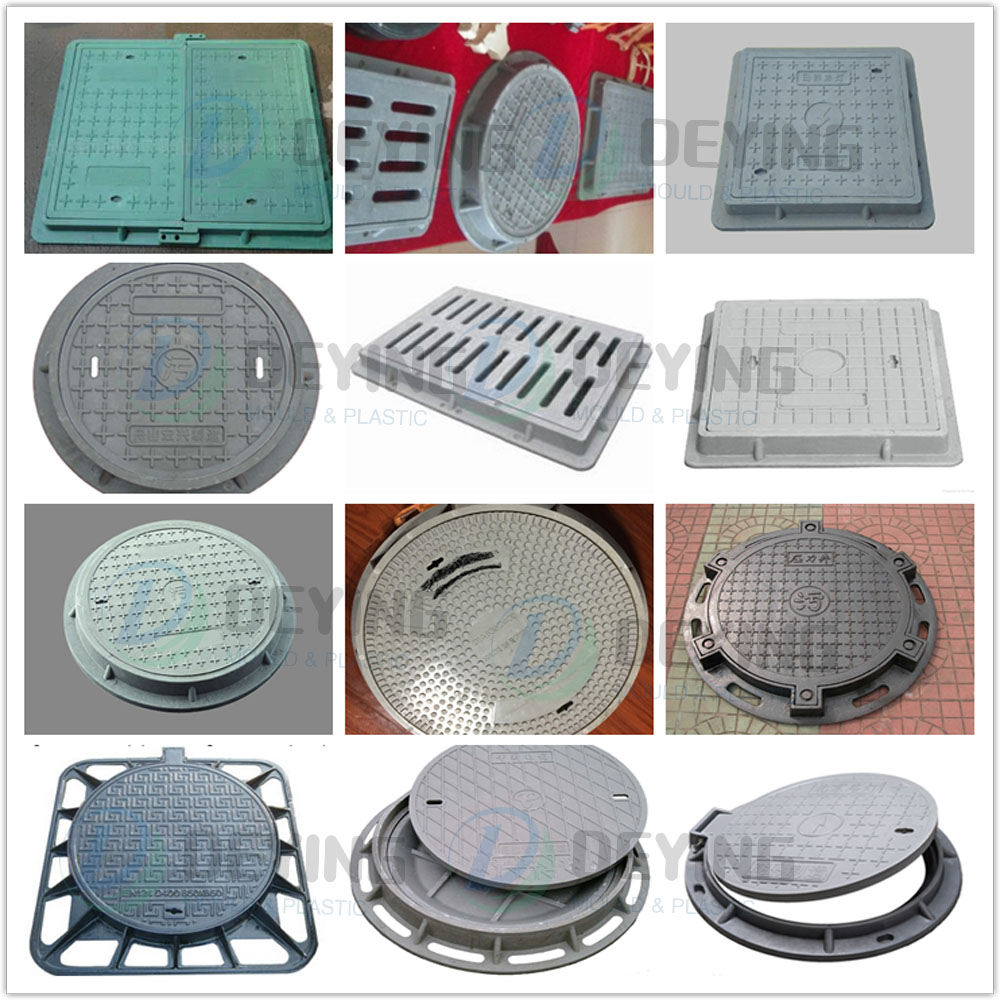

Nowadays, the manhole cover molds in many places are beautiful, and the designs are very beautiful. Basically, what kind of pattern effects can be realized, such as characters, landscapes, buildings, animals, and so on.

With the development of China's economy, my country's manhole cover mold has become a superpower in housing construction, and it is also the focus of every construction company, government and all walks of life. It has been used in many building constructions.

FRP compression manhole cover mould products have the following characteristics:

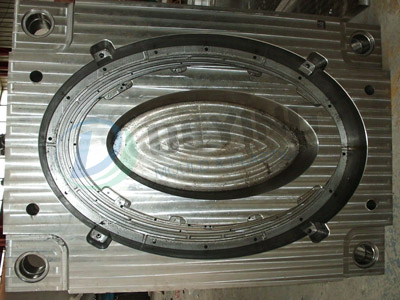

1. The edges of the mold are neat and free of burrs; the concave-convex groove is used for sealing to solve the problem of slurry leakage;

2. The surface layer is made of agate gel coat, no wrinkles, no layering, no bubbles, good finish, high brightness above 80%;

3. The size is accurate and is strictly customized according to customer needs;

4. High strength, good toughness, wear resistance, high temperature resistance above 100℃;

5. Durable, high hardness, 1000 molds can be demolded.

The manhole cover mold of the new composite material is different from the old manhole cover mold. The new product adopts polymer composite material, which is more robust and durable, and has an exquisite appearance, which is conducive to the decoration of the manhole cover and has a great advantage in weight.

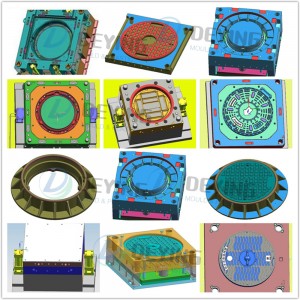

The types of manhole cover molds are: cement round manhole cover mold, county municipal manhole cover mold, inspection manhole cover mold, cement water manhole cover mold

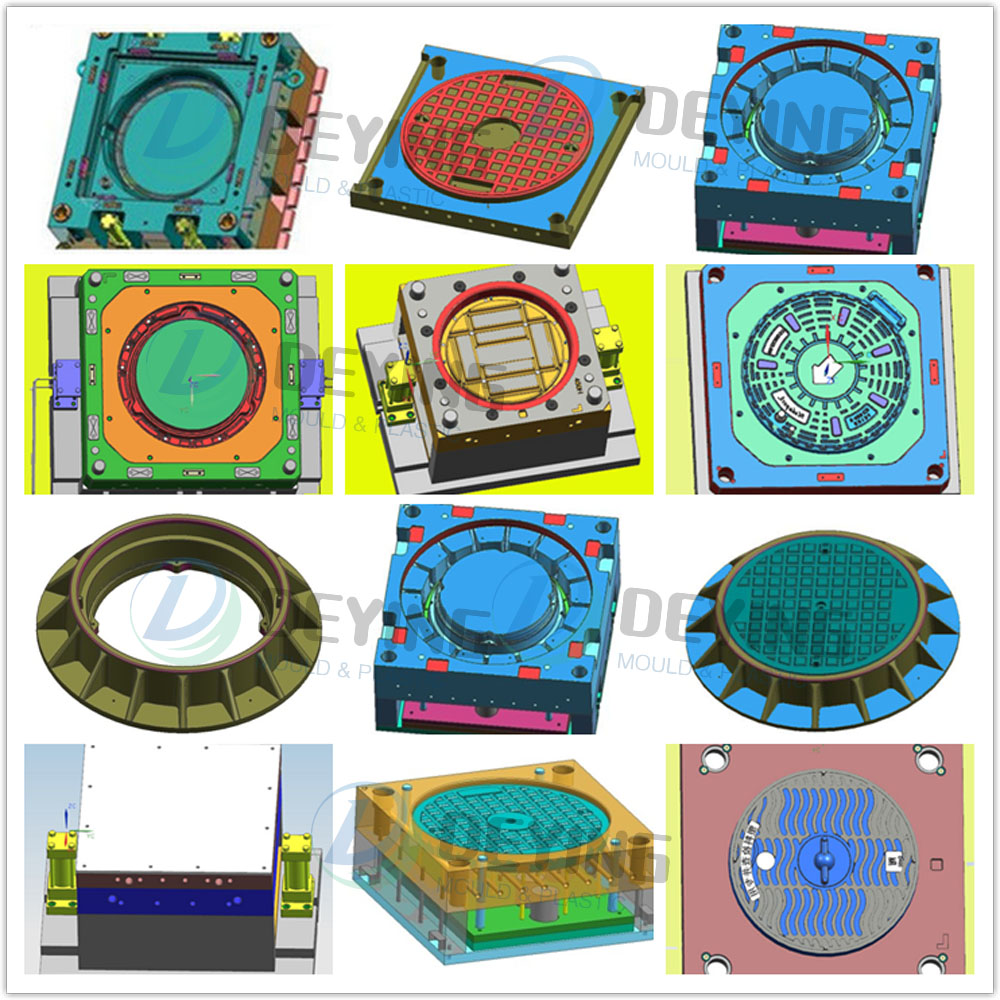

The main advantages of the mold of the compression molding process:

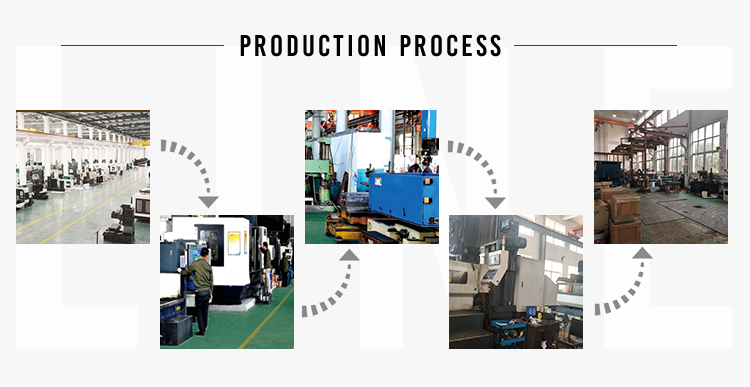

1. High production efficiency, easy to realize specialized and automated production;

2. The product has high dimensional accuracy and good repeatability;

3. The surface is smooth and clean without secondary modification;

4. It can form products with complex structure at one time;

5. Because of mass production, the price is relatively low.

The shortcomings of compression molding are that the manufacturing of compression molds is complicated, the investment is relatively large, and the limitation of the press machine, it is suitable for mass production of small and medium composite materials. With the continuous improvement and development of metal processing technology, press manufacturing level and synthetic resin process performance, press tonnage and table size continue to increase, and the molding temperature and pressure of molded materials are relatively reduced, making the size of molded products gradually move toward Large-scale development, and now it has been able to produce large-scale automobile parts, bathtubs, integral toilet components, etc.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

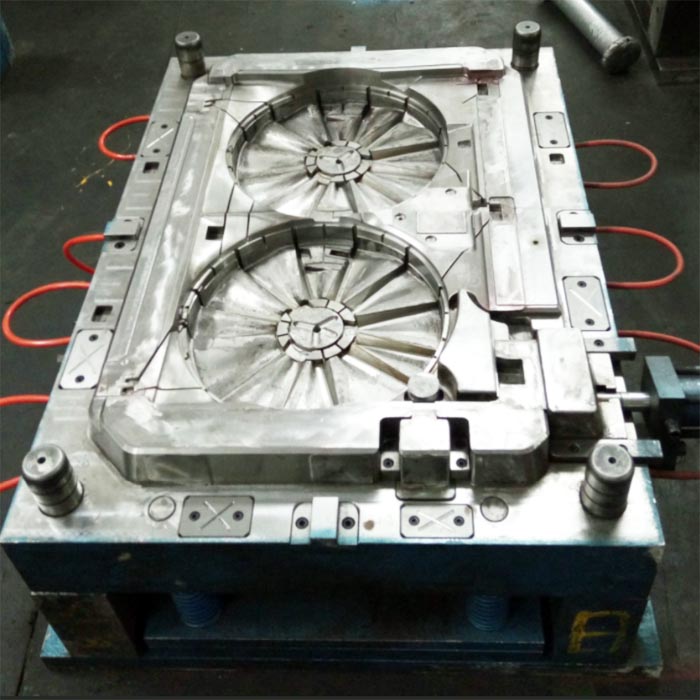

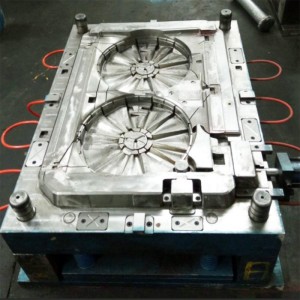

Anti-Theft Manhole Covers molding with Frame mould

-

SMC Sheet Molding Compound mould for Manhole Cover

-

Composite Round and Square FRP Manhole Cover mold

-

Round Telecom Composite Manhole Cover mould Pro...

-

Long Fiber Reinforced SMC Sheet Molding Compoun...

-

Round glass fiber reinforced plastic manhole co...