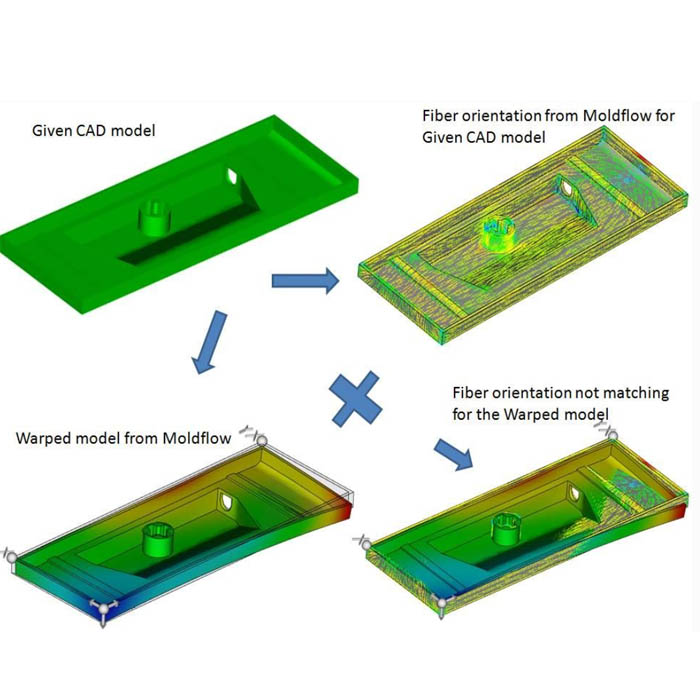

Composite materials are made up of two or more materials with different properties through physical or chemical methods to form materials with new properties. With the broadening of the application field of composite materials, the composite material molding industry has developed rapidly, the old molding process is becoming more and more perfect, and new molding methods are constantly emerging. Commonly used processes include hand lay-up, injection molding, resin injection (RTM), compression molding (BMC, SMC), and vacuum diversion molding processes.

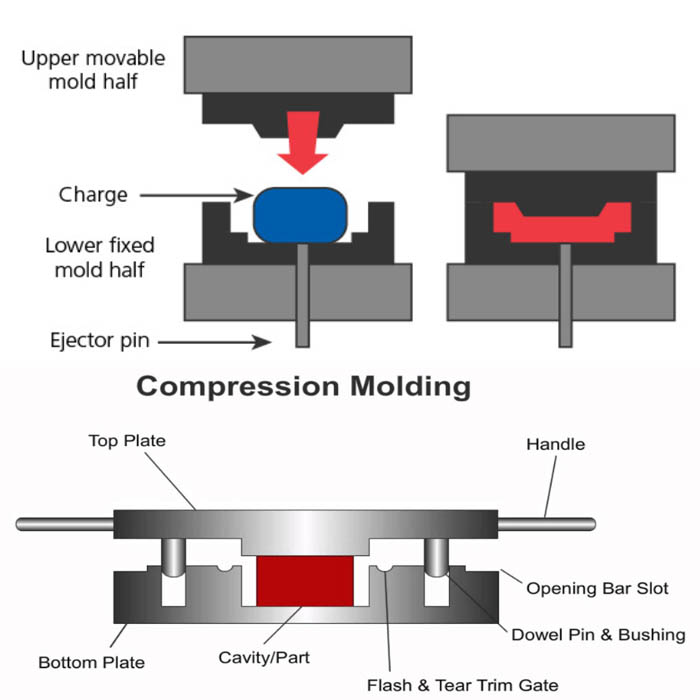

To make high-precision composite products, composite molds are the most important part of the entire manufacturing process. And the shape and appearance of the product need to be guaranteed by the mold. The composite material mold usually puts the composite material into a hot pressing mold, and then melts the composite material by heating the mold. The mold is equipped with an ejection mechanism to eject the molded product to separate it from the mold. Common heating methods for composite molds include oil heating, electric heating, and steam heating.

Composite molds vary greatly, depending on the industry and application, involving multiple fields such as automotive, electrical, sanitary ware, building materials, and aerospace. Compared with metal molds, composite material molds have many advantages, so what are the advantages of composite material molds?

1. The composite material mold is lighter, and the reduced weight helps in the transportation of the mold.

2. Lower specific heat capacity, less heat required during processing, and easier to control the increase and decrease of curing temperature, thereby shortening the time to pass through the autoclave.

3. The manufacturing and maintenance cost is low, and the composite material mold uses a common master mold to form multiple repeated molds.

As a mature composite mold manufacturer in China, DEYING manufactures various types of glass fiber composite molds (glass fiber reinforced plastic molds, such as SMC, BMC, GMT, LFT), carbon fiber composite molds, and LWRT composite molds.

The molds that DEYING has manufactured include: spoiler templates on trucks, fenders, bumpers, front panel molds, hoods, doors, bottom guards, roofs, seat backs, luggage molds, etc. and electrical appliances on cars. Boxes and bathroom door panels and basin molds, etc. The composite molds we produce have been effectively optimized, have a longer service life, lower manufacturing costs, and their products can achieve higher precision.

Sheet molding compound is a type of reinforced polyester containing glass or carbon fibers. The fibers, which are typically 1” or greater in length, are suspended in a bath of resin – usually epoxy, vinyl ester, or polyester.

SMC is a combination of long chopped glass strands, mineral fillers and liquid thermosetting resin in the form of a malleable sheet material. Processing of SMC of is typically done by compression or injection molding.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com