-

Fiberglass Manhole Cover Mould Customized SMC Compression Mold

Manhole cover mold is an indispensable product in our daily life. It has high use density and strong durability. The product is required to have a certain degree of toughness and firmness, and it can be used for a long time. We must choose high-quality manhole cover mold products.

-

New Design Manhole Cover Moulds Plastic with High Quality

The manhole cover mold technology is leading in the country, based on advanced equipment, unremittingly pursuing perfect service and striving to beautify mankind” principle. Our company’s business philosophy: professionalism creates quality, integrity wins the market. “Is always adhered to the business philosophy.

-

Injection Mould Manhole cover with Three Ways Mold

The manhole cover mold has very outstanding advantages. The most important thing is the low cost, so the sales volume is very good. The manhole cover mold has a wide range of uses. It is used in many families, manors, and parks. Choosing a more suitable manhole cover is for people. Life safety is also very important

-

BMC SMC Plastic Injection Molding Products Manhole Cover Mould

I believe that many people don’t know what it is for the first time they see it if it is not on the road. Even if it is installed on the road, it is easy to be misunderstood as other things. The beautiful manhole cover mold protects the safety of pedestrians at the same time. Played a certain role in the decoration of the city

-

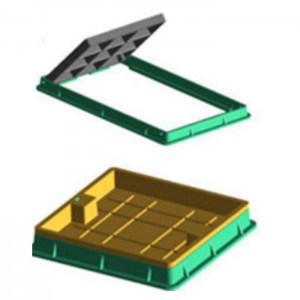

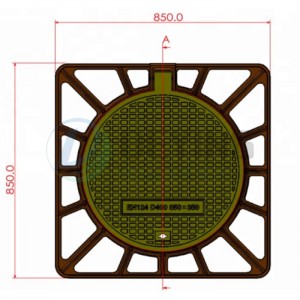

Anti-Theft B125 Square SMC BMC Manhole Cover molds 600X600

The manhole cover mold is still fast in demolding speed, and it can be demolded during the production process, and uninterrupted production can be achieved, which is several times higher than the production volume of traditional manhole cover molds.

-

Fiberglass Reinforced Plastic Heavy Duty Manhole Cover moldings

The size of the manhole cover mold is divided into circular diameter 700mm 600mm 500mm 800mm

Square 500mm 600mm

Steel mold size can be customized according to needs -

Composite Cable Trench Cover Plate mould FRP Manhole Trench Cover mold

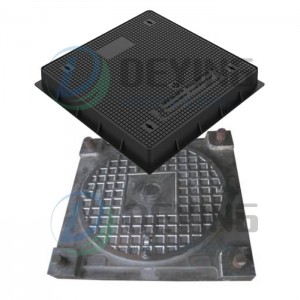

Manhole cover molds are mainly divided into two types according to the different materials used: one is a manhole cover plastic mold, the other is a manhole cover steel mold, and the two molds are of different materials. Both are special molds for the production of cement anti-theft manhole covers. Among them, the sewage manhole cover mold is the most used. widely.

-

High Quality and Low Price Fiberglass Plastic SMC Manhole Cover molding Customized

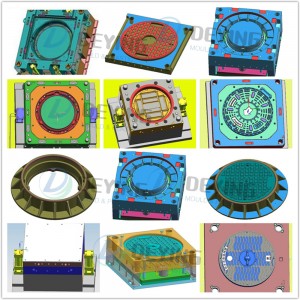

The manhole cover mould produced by DEYING MOLD is more and more widely used in urban planning and road construction. Such molds help municipal construction and beautify the urban environment.

-

Composite Round and Square FRP Manhole Cover mold

DEYING MOULD can manufacture manhole cover molds of various sizes according to customer requirements, and is also happy to solve various technical problems for customers.

-

Polymer Resin Round Manhole Cover molds with Competitive Price

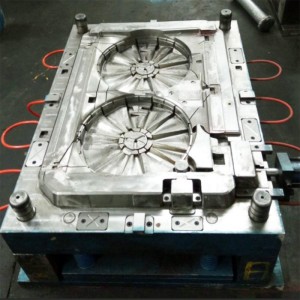

Our main business: SMC grille mold, SMC manhole cover mold, SMC compression mold

There are three large-scale gantry CNC machines, precision grinders, drilling machines, vertical CNC machining centers, etc. Adhering to the enterprise spirit of “striving for perfection and pursuing excellence”. -

Round Telecom Composite Manhole Cover mould Professional Supplier

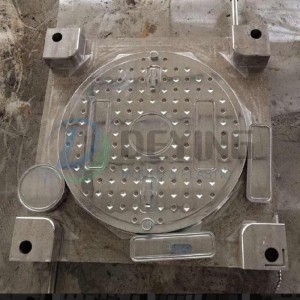

The fiber glass manhole cover mold produced by DEYING MOLD has the characteristics of high precision, easy demolding, fast heating, stable operation, and environmental protection. It can be customized according to customer requirements.

-

Glass Fiber Reinforced Plastic Sewer Cover Manhole Cover mouldings

DEYING is good at producing FRP grating moulds, SMC BMC moulded manhole cover moulds, FRP moulded product moulds,Widely used in work platforms and equipment platforms in petroleum, chemical, electric power, electroplating and other industries

-

Square and Round Manhole Cover molds with Frame mould

DEYING MOLD’s main business: FRP grating molds, FRP molded molds, molded flange products, manhole cover molds

There are three large-scale gantry CNC machines, precision grinders, drilling machines, vertical CNC machining centers, etc. Adhering to the enterprise spirit of “striving for perfection and pursuing excellence”. -

Hot sales Composite Round Resin FRP Manhole Cover molds

DEYING MOULD develops perfect mold solutions for the production of composite manhole cover molds based on customers. With a “striving for perfection” work attitude, relying on superb technology and advanced mold production, processing, and testing equipment, we prefers high-quality mold accessories suppliers. Provide customers with high-quality molds.

-

FRP GRP Fiberglass Manhole Cover Mould

The manhole cover mold is characterized by the specification of the size of the manhole cover produced. Used in roads and other places, the manhole cover mold is not restricted by the size and shape. It can produce various sizes of manhole covers according to customer requirements, and can be strengthened and customized in various sizes, even on the appearance of cement manhole covers. Printing all kinds of words and patterns has more propaganda effect.

-

New Design Square SMC Manhole Cover Moulds

Manhole cover mold technology is leading in the country, based on advanced equipment, unremittingly pursuing perfect service and striving for the beautification of mankind” principle. Our factory’s business philosophy: professionalism casts quality, integrity wins the market.” is the business philosophy that I have always adhered to.

-

Heavy Duty Circular Round Manhole Cover molding Supplier

quality smc bmc compression manhole cover mould made in China taizhou huangyan,DEYING is the leading plastic injection mould, BMC/ SMC/GMT/ LFT mould manufacturer

-

Long Fiber Reinforced SMC Sheet Molding Compound for Manhole Cover moulds

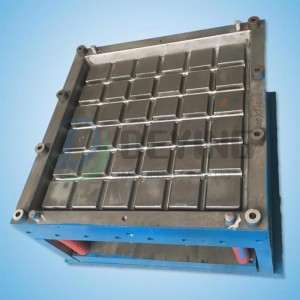

compression Manhole Cover Mould,Currently, most of the manhole covers are using SMC or BMC compression molding technology to replace steel parts -

Mold Factory sell SMC BMC FRP Manhole Cover moulds

Compression molds are used in industry, agriculture, transportation, electrical, chemical, construction, machinery and other fields. Because of the reliable quality of molded products, they have also been used in weapons, aircraft, missiles, and satellites.Professional Mold Factory sell SMC BMC FRP Manhole Cover moulds

-

FRP Composite Manhole Cover molds Custom Made

Compression molding manhole cover mold-compression mold manufacturing professional manufacturer DEYING mold compression molding is the operation of first putting powdery, granular or fibrous plastic into the mold cavity at the molding temperature, and then closing the mold and pressing it to shape and solidify .

-

trench Cover Heavy Duty Manhole Cover molds

The company’s good cooperative relationship with industry experts can provide you with integrated fiberglass manhole cover mould and mold solutions! Welcome new and old friends to visit the factory and guide the work!

-

En124 Standard D400 Square and Round Sewer Manhole Cover Frame mould

The composite manhole cover mold is favored by customers, mainly because the production materials do not contain metal, and the composite manhole cover solves the problem of the manhole cover being stolen.

-

En124 B125 C250 Composite Resin SMC FRP Square Manhole Covers moulds

The molded manhole cover mold is used to produce composite manhole covers. It is made of the latest polymer composite materials. The steel bar is the most important internal skeleton. It is produced by high-temperature molding and has high strength.

-

Reinforced SMC Sheet molding compound manhole cover mould

Compression molding (also known as compression molding or compression molding) is the operation of first putting powdered, granular or fibrous plastic into the mold cavity at the molding temperature, and then closing the mold and pressing it to shape and solidify it. Compression molding can be used for thermosetting plastics, thermoplastics and rubber materials.Supplying SMC Sheet molding compound manhole cover mould,welcome contact by free.