-

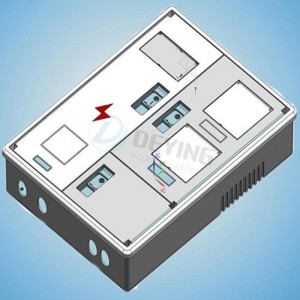

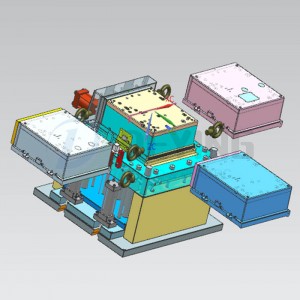

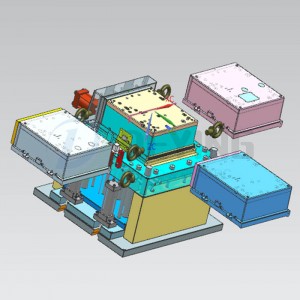

gas meter box mould China taizhou SMC BMC DMC FRP mold factory

Application fields of SMC products

SMC composite materials and SMC molded products have excellent electrical insulation properties, mechanical properties, thermal stability, and chemical resistance. Therefore, the application range of SMC products is quite wide, mainly in the following application areas:

1. Applications in the electrical industry.

2. Application in the automobile industry.

3. Application in railway vehicles.

4. Application in communication engineering.

5. The application of explosion-proof electrical equipment enclosures, etc. -

electricity meter box mould smc bmc frp mold manufacture

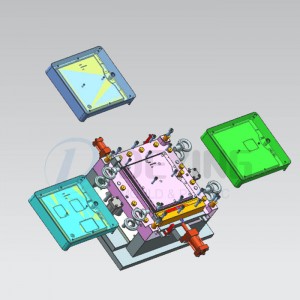

DEYING molds supplying compression molding and have cooperated with international manufacturers in many fields such as aerospace, automobiles, trucks, high-speed rail, medical, etc., and have been approved by them and issued authorization licenses. Provide customers with solutions in the application of composite materials, and provide customers with feasibility analysis and technical support in the development of new products. While developing for the high requirements of the surface of SMC products, MDC uses a vacuum exhaust system on the mold; while developing for SMC automotive parts, it uses in-mold spraying technology according to customer requirements to integrate the products in the production process.

-

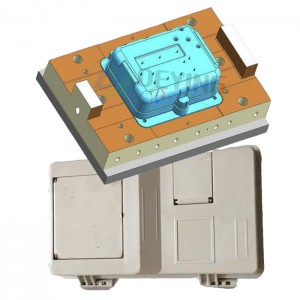

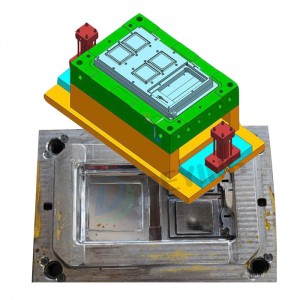

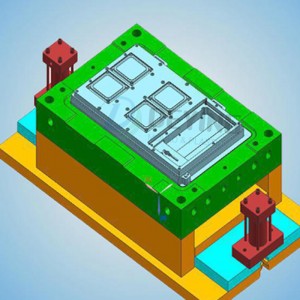

thermosetting compression BMC SMC mold solution

Advantages of compression molding: (1) The loss of raw materials is small and will not cause too much loss (usually 2% to 5% of product quality). (2) The internal stress of the product is very low, and the warpage deformation is also small, and the mechanical properties are relatively stable. (3) The wear of the mold cavity is small, and the maintenance cost of the mold is low. (4) The cost of molding equipment is lower, and its mold structure is simpler, and its manufacturing cost is usuall... -

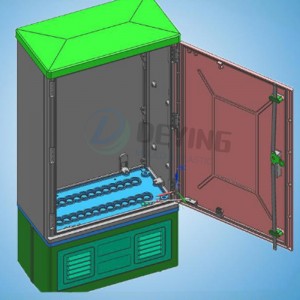

fiberglass electric SMC meter boxes mold FRP gas box mould

SMC glass fiber reinforced plastic meter box is made of SMC unsaturated polyester glass reinforced fiber compression molding.fiberglass electric SMC meter boxes mold FRP gas box mould professional maker in taizhou 1. It solves the shortcomings of wooden, steel, and plastic meter boxes that are easy to age, easy to corrode, poor insulation, poor cold resistance, poor flame retardancy, and short life. The excellent performance of the glass fiber reinforced plastic meter box has absolute sealin... -

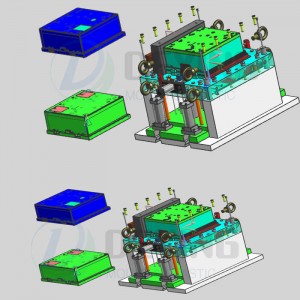

bmc compression mould for Distribution meter Box

Advantages of compreFeatures of molded products: The shrinkage of the product is small and the repeatability is good: A mold with a large number of cavities can be placed on a given template, with high productivity: Can be adapted to automatic feeding and automatic removal of products: High production efficiency, easy to realize specialized and automated production: The product has high dimensional accuracy and good repeatability: Smooth surface, no need for secondary modification: Products w... -

fiberglass compression mold smc molding maker in taizhou

The unique performance of SMC composite material solves the shortcomings of wooden, steel, and plastic meter boxes that are easy to age, easy to corrode, poor insulation, poor cold resistance, poor flame retardancy, and short life. The excellent performance of composite meter boxes has absolute sealing and waterproofing. Performance, anti-corrosion performance, anti-electricity theft performance, never need grounding wire, beautiful appearance, safety protection with lock and lead seal, long ... -

smc bmc Electricity Meter box mould plastic injection meter gas box molds

Deying Mould is specialized in plastic injection meter box mold and smc bmc compression meter box molding.Electricity gas box mould manufacture factory in China -

-

-

-

-

-

-

SMC junction box housing mould

We have 20 years experience for SMC BMC FRP DMC compression junction box housing mould making The characteristics of the SMC process are: (1) Easy to operate. The entire production process is easy to mechanize and automate, and the production efficiency is high, which improves the working environment and working conditions of the wet forming. (2) The product is not arbitrarily strong. The molding process can be changed to meet the different requirements of different products by changing the t... -

-

-

-

-