-

High Quality Injection Mold of Manhole Covers suppliers

The composite molds we produce have been effectively optimized, have a longer service life, lower manufacturing costs, and their products can achieve higher precision.

Commonly used processes include hand lay-up, injection molding, resin injection (RTM), compression molding (BMC, SMC), and vacuum diversion molding processes.

-

Round glass fiber reinforced plastic manhole cover mold

DEYING MOULD has many years of experience in manufacturing composite material molds. The molds that have been manufactured include: spoiler templates, mudguards, bumpers, front panel molds on trucks, hoods, doors, bottom guards, and roofs on cars

-

compression molding Hot press forming moulds maker

Compression molding is a manufacturing process where a measured amount of molding material that’s generally preheated (typically referred to as a charge) is compressed into the desired form using two heated molds

-

drain cover and frame mold manufacturer SMC BMC planting grass cover mould

Currently, most manhole covers use SMC or BMC materials instead of steel parts. The ideal performance of SMC material can reach 400-900KN, which can ensure the passage of heavy trucks. In addition, the SMC manhole cover has the advantages of high strength, high precision and corrosion resistance, and its weight is reduced by 1/3 compared with steel parts.

-

SMC BMC manhole cover mould FRP compression composite Telecom cover mold supplier

SMC is sheet molding compound.The main raw materials of SMC are composed of GF (special yarn), UP (unsaturated resin), low shrinkage additives, MD (filler) and various additives.

SMC products is not easy to deform and has excellent heat resistance; it can maintain its performance well in cold and hot environments, and is suitable for outdoor anti-ultraviolet and waterproof functions.

-

fiberglass mould for Various types of Connector

fiberglass mould for Various types of Connector The grid is interwoven by glass fiber and molded by resin casting. The glass fiber reinforced plastic grid sheet with many regular rectangular and square spaces has two-dimensional homogenous mechanical characteristics. Can be widely used in petroleum, chemical electronics, power, paper, printing and dyeing, electroplating, FRP grating Work platforms, equipment platforms, drilling platforms, walkways, etc. in marine exploration, sewage treatment... -

High quality compression SMC kitchen sink mould

DEYING Mould is a Taizhou mould manufacturer. We provide almost all series of sanitary ware moulds, such as SMC laundry tub moulds.

DEYING has mold finishing technology and mold mirror polishing technology. We have multiple SMC laundry tank mold production lines to ensure that your orders are completed on time and with good quality. For your SMC laundry tank, we will help you achieve efficient production. In addition, relying on DEYING’s accumulated years of FRP material technology, we ensure the service life, smoothness and use experience of your laundry tub, and help you enhance your market competitiveness.

-

compression mold household products FRP Bathroom Mould

DEYING provides complete bathroom solutions, including customized molds and mold design services, and provides pre-sales and after-sales services. Regardless of your needs, your project will get full attention in DEYING. We will meet or exceed your expectations at any stage from the product design stage to mold processing and mold trial.

-

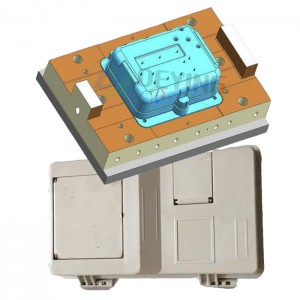

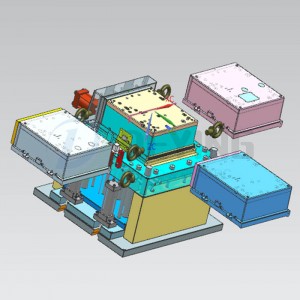

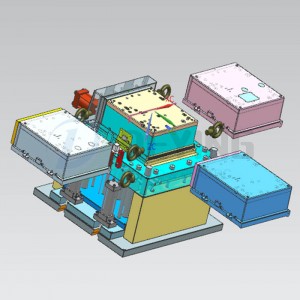

gas meter box mould China taizhou SMC BMC DMC FRP mold factory

Application fields of SMC products

SMC composite materials and SMC molded products have excellent electrical insulation properties, mechanical properties, thermal stability, and chemical resistance. Therefore, the application range of SMC products is quite wide, mainly in the following application areas:

1. Applications in the electrical industry.

2. Application in the automobile industry.

3. Application in railway vehicles.

4. Application in communication engineering.

5. The application of explosion-proof electrical equipment enclosures, etc. -

electricity meter box mould smc bmc frp mold manufacture

DEYING molds supplying compression molding and have cooperated with international manufacturers in many fields such as aerospace, automobiles, trucks, high-speed rail, medical, etc., and have been approved by them and issued authorization licenses. Provide customers with solutions in the application of composite materials, and provide customers with feasibility analysis and technical support in the development of new products. While developing for the high requirements of the surface of SMC products, MDC uses a vacuum exhaust system on the mold; while developing for SMC automotive parts, it uses in-mold spraying technology according to customer requirements to integrate the products in the production process.

-

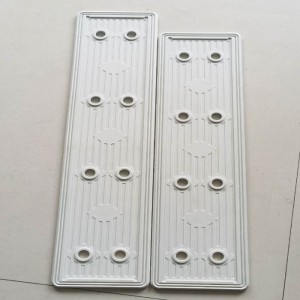

China taizhou huangyan compression smc mold cable bracket support mould

SMC has the advantages of superior corrosion resistance, soft quality, easy engineering design, flexibility, etc. Its mechanical properties are comparable to some metal materials, and the products it manufactures have the advantages of good rigidity, deformation resistance, and wide operating temperature range.

At the same time, the size of SMC products is not easy to deform and has excellent heat resistance; it can maintain its performance well in cold and hot environments, and is suitable for outdoor anti-ultraviolet and waterproof functions.

-

SMC Sheet molding compound compression mould

Sheet molding compound is a type of reinforced polyester containing glass or carbon fibers. The fibers, which are typically 1” or greater in length, are suspended in a bath of resin – usually epoxy, vinyl ester, or polyester.

SMC is a combination of long chopped glass strands, mineral fillers and liquid thermosetting resin in the form of a malleable sheet material. Processing of SMC of is typically done by compression or injection molding.

-

Composite material compression mold professional producer

Composite materials are made up of two or more materials with different properties through physical or chemical methods to form materials with new properties. With the broadening of the application field of composite materials, the composite material molding industry has developed rapidly, the old molding process is becoming more and more perfect, and new molding methods are constantly emerging. Commonly used processes include hand lay-up, injection molding, resin injection (RTM), compression molding (BMC, SMC), and vacuum diversion molding processes.

-

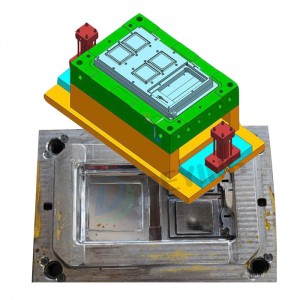

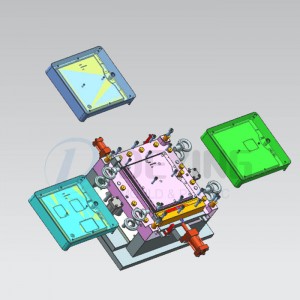

bmc compression mould for Distribution meter Box

Advantages of compreFeatures of molded products: The shrinkage of the product is small and the repeatability is good: A mold with a large number of cavities can be placed on a given template, with high productivity: Can be adapted to automatic feeding and automatic removal of products: High production efficiency, easy to realize specialized and automated production: The product has high dimensional accuracy and good repeatability: Smooth surface, no need for secondary modification: Products w... -

fiberglass compression mold smc molding maker in taizhou

The unique performance of SMC composite material solves the shortcomings of wooden, steel, and plastic meter boxes that are easy to age, easy to corrode, poor insulation, poor cold resistance, poor flame retardancy, and short life. The excellent performance of composite meter boxes has absolute sealing and waterproofing. Performance, anti-corrosion performance, anti-electricity theft performance, never need grounding wire, beautiful appearance, safety protection with lock and lead seal, long ... -

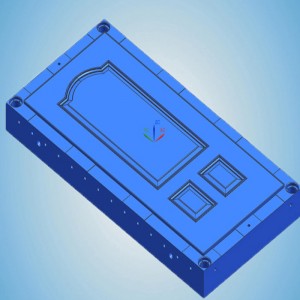

fiberglass electric SMC meter boxes mold FRP gas box mould

SMC glass fiber reinforced plastic meter box is made of SMC unsaturated polyester glass reinforced fiber compression molding.fiberglass electric SMC meter boxes mold FRP gas box mould professional maker in taizhou 1. It solves the shortcomings of wooden, steel, and plastic meter boxes that are easy to age, easy to corrode, poor insulation, poor cold resistance, poor flame retardancy, and short life. The excellent performance of the glass fiber reinforced plastic meter box has absolute sealin... -

thermosetting compression BMC SMC mold solution

Advantages of compression molding: (1) The loss of raw materials is small and will not cause too much loss (usually 2% to 5% of product quality). (2) The internal stress of the product is very low, and the warpage deformation is also small, and the mechanical properties are relatively stable. (3) The wear of the mold cavity is small, and the maintenance cost of the mold is low. (4) The cost of molding equipment is lower, and its mold structure is simpler, and its manufacturing cost is usuall... -

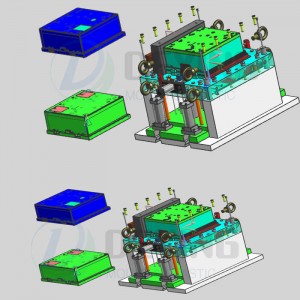

smc bmc Electricity Meter box mould plastic injection meter gas box molds

Deying Mould is specialized in plastic injection meter box mold and smc bmc compression meter box molding.Electricity gas box mould manufacture factory in China -

-

-

-

SMC junction box housing mould

We have 20 years experience for SMC BMC FRP DMC compression junction box housing mould making The characteristics of the SMC process are: (1) Easy to operate. The entire production process is easy to mechanize and automate, and the production efficiency is high, which improves the working environment and working conditions of the wet forming. (2) The product is not arbitrarily strong. The molding process can be changed to meet the different requirements of different products by changing the t... -

SMC BMC Compression Insulator block mould

SMC BMC Compression Insulator block mould maker BMC (DMC) dry-type transformer insulation blocks are used for insulation and fixing on dry-type transformers. It can ensure the stability and insulation performance of dry-type transformers during transportation and long-term operation, and can withstand transformers at work. The high temperature and hot air aging generated in the BMC dry type transformer insulating block is integrally molded by high temperature and high pressure. BMC dry-type t... -