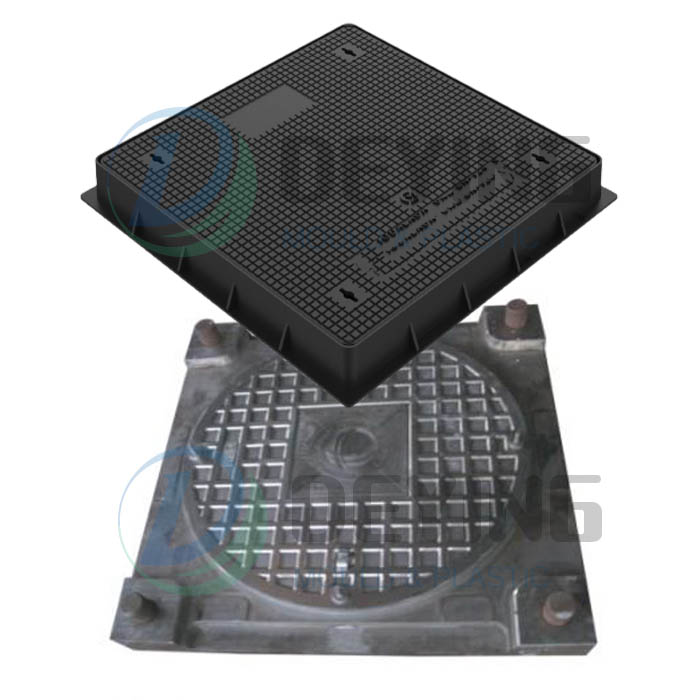

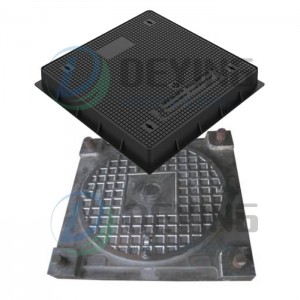

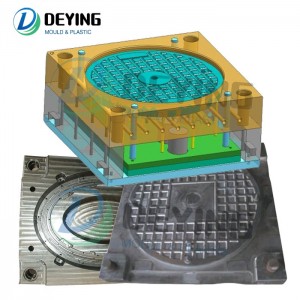

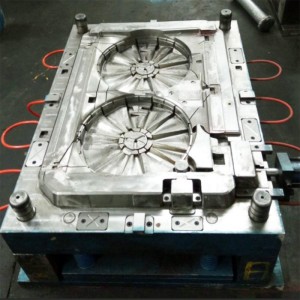

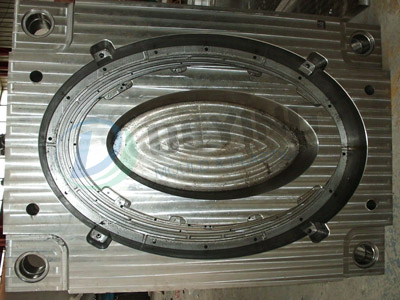

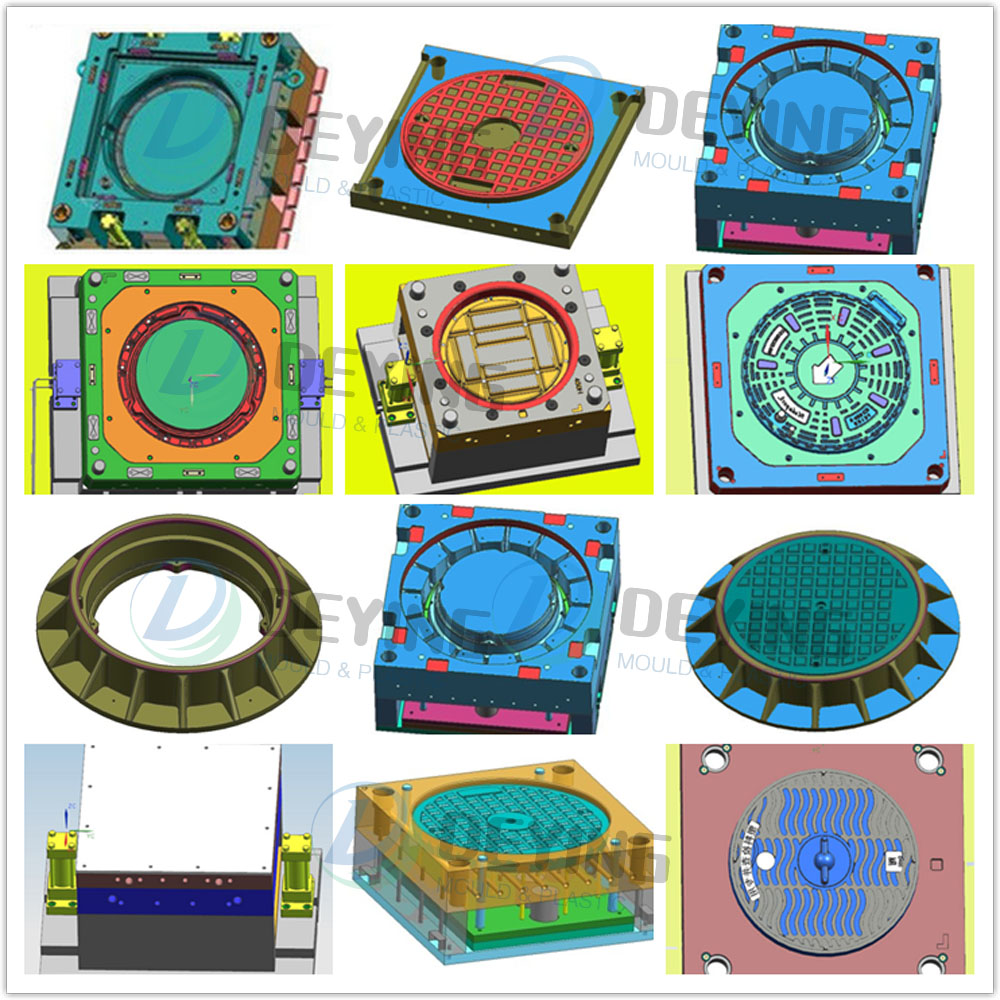

The characteristics of the composite manhole cover mold are as follows: good wear resistance and aging resistance, the characteristics of the composite material itself and the addition of special anti-ultraviolet additives, so that the product has excellent light resistance and heat resistance, and the surface adopts the idea of making grinding wheels, which is reasonable The structure and the use of high wear-resistant materials. Effectively organize the wear resistance of the product. The appearance is strong and the service life is long. Made into marble texture, or made according to user needs. The use of unique materials, high-performance resin, glass fiber and special production technology can effectively increase the service life of the product, provide consumers with high-quality products, and reduce production costs.

The manhole cover mold of the new composite material is different from the old manhole cover mold. The new product adopts polymer composite material, which is more robust and durable, and has an exquisite appearance, which is conducive to the decoration of the manhole cover and has a great advantage in weight.

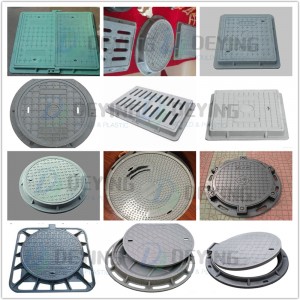

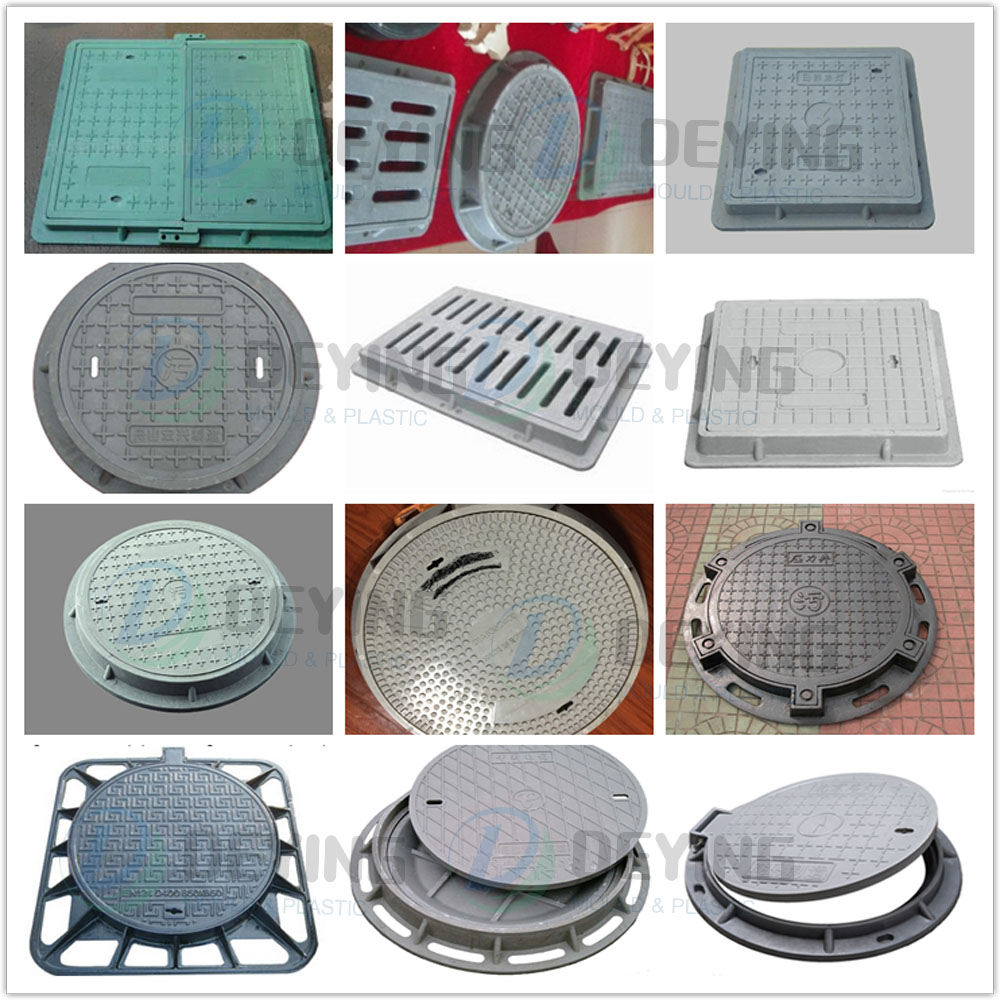

The types of manhole cover molds are: cement round manhole cover mold, county municipal manhole cover mold, inspection manhole cover mold, cement water manhole cover mold

Drainage facilities, in cities, towns, rural areas and other places, it is necessary to build a large number of drainage facilities. If it is farmland, rainwater can directly flow into the field for irrigation. In urban areas, drainage facilities need to be constructed. Drainage facilities require ditches and manhole cover molds, according to specific It is required to be used. At the same time, the cement slope produced by the plastic mold has a smooth surface and is suitable for use in towns and cities. This mold is working hard to build our motherland.

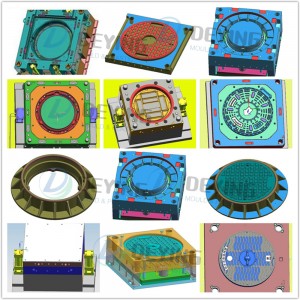

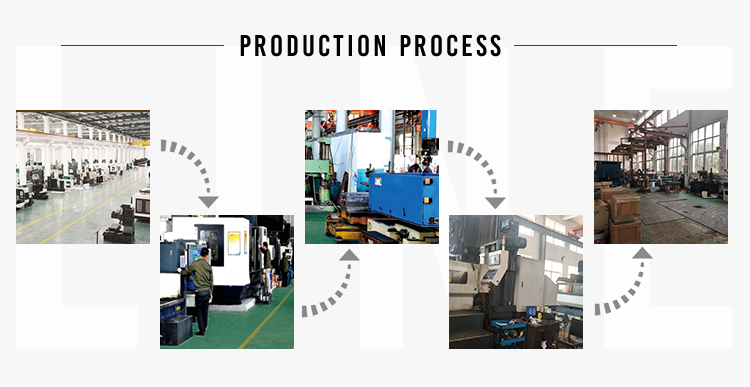

From the perspective of technological development trends, the mold development trend can be analyzed from the following six most basic aspects:

1-New materials-new materials for molds and new molds for forming new materials for formed products

2-New technology-new forming technology and new mold processing technology

3-New technology-technological advancement drives mold production to gradually develop in the direction of ultra-high speed, ultra-precision and high automation

4-Informatization-digital production, informatization management, full use of it technology

5-Networking-integrate and make good use of the global network of the world

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com