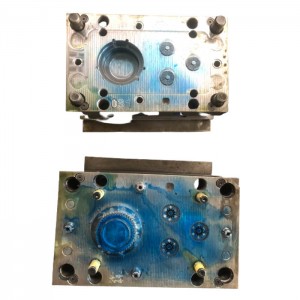

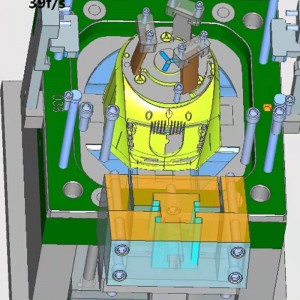

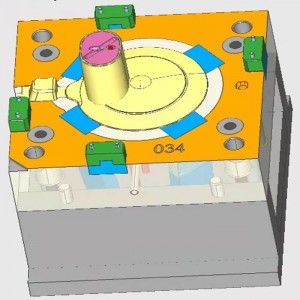

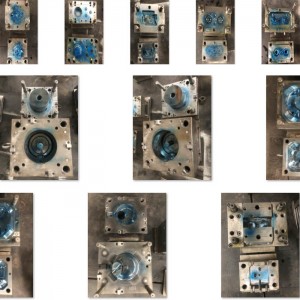

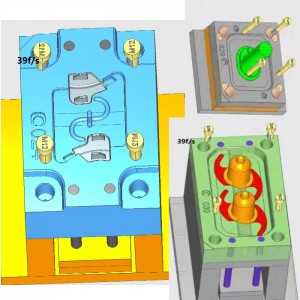

Juicer molds can be divided into: guiding system, supporting system, forming part system, pouring system, cooling system, ejection system, exhaust system according to the overall functional structure.

How can I make a mold for an injection molding juicer? First, select the right steel material for the mold base and the mold core cavity. In addition, you must use high-hardness steel as the mold base, and then select the appropriate mold standard parts. A good plastic material filling system requires special hot runner system assistance. Forming, and to ensure that the cooling system achieves the best results. For injection molds, Taizhou DEYING MOLD is a plastic mold manufacturer that specializes in manufacturing and processing injection molds. It also provides plastic product processing services, high-speed milling external processing services, and we pay great attention to the quality of molds.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com