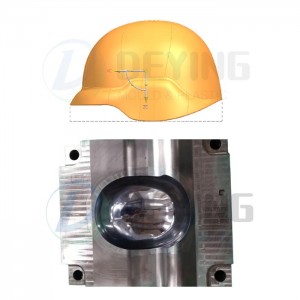

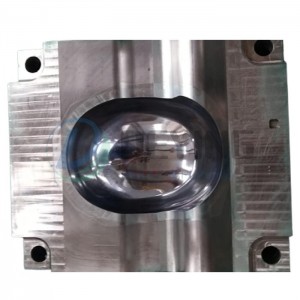

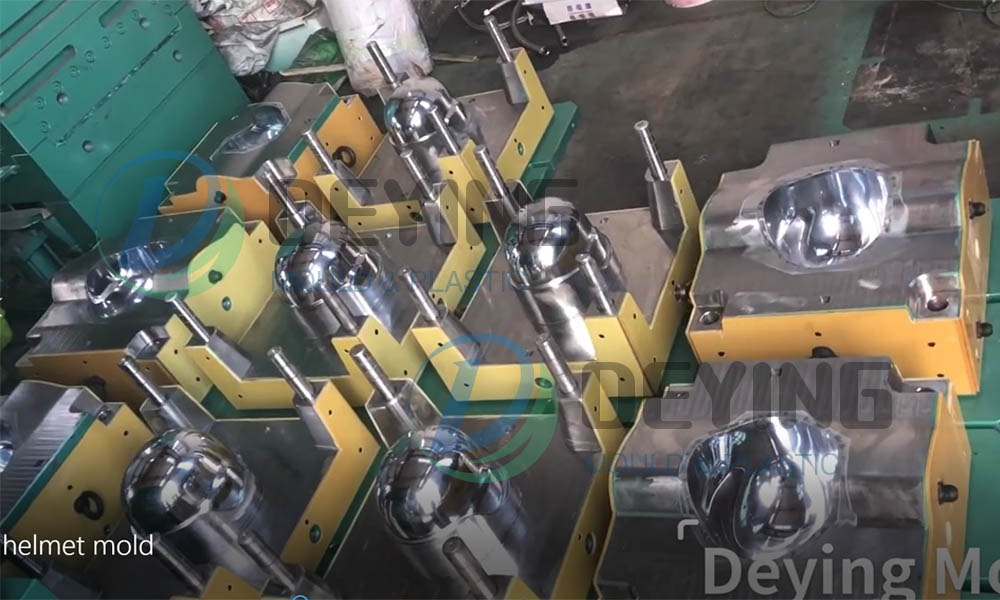

Deying's unique mould technology enables it to manufacture UHMWPE bulletproof ballistic helmets mould with high quality, which is typically up to 100% satisfaction

Our factory has been involved in the design and development of military product molds since 2000. Experience. Exported abroad

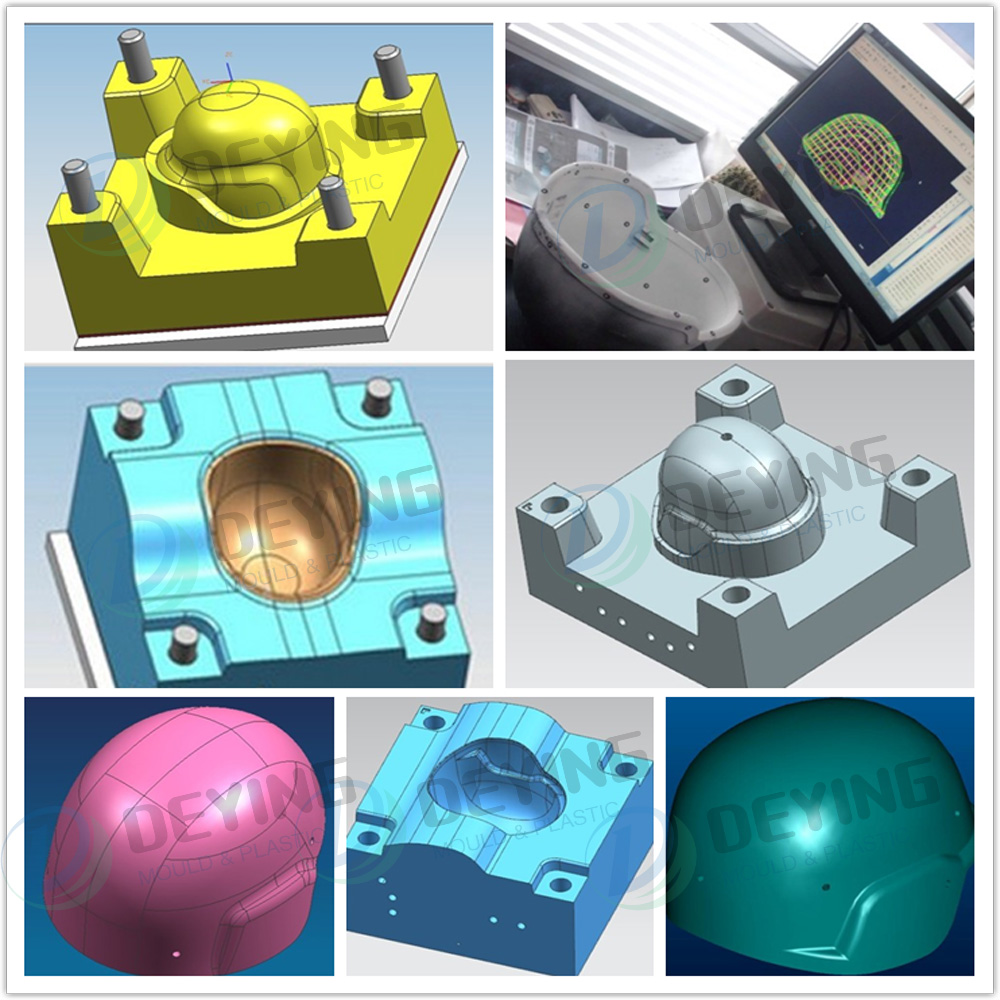

What are the factors that affect the processing structure of helmet molds?

1. Cavity layout. Determine the number of cavities and their arrangement according to the geometric structure characteristics of the plastic parts, the dimensional accuracy requirements, the batch size, the difficulty of mold manufacturing, and the mold cost.

2. Determine the parting surface. The position of the parting surface should be conducive to mold processing, venting, demolding and molding operations, and the surface quality of plastic parts.

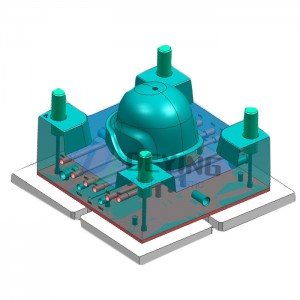

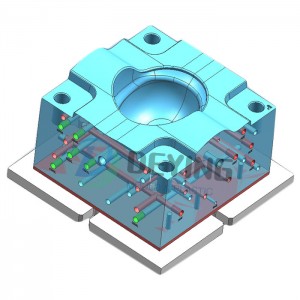

3. Determine the pouring system (the shape, location and size of the main runner, sub-runner and gate) and the exhaust system (exhaust method, position and size of the exhaust slot).

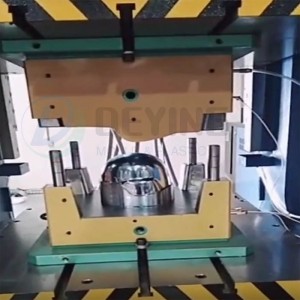

4. Select the ejection method (ejector, pipe, push plate, combined ejector), determine the undercut treatment method and core-pulling method.

5. Determine the cooling and heating method, the shape and location of the heating and cooling groove, and the installation location of the heating element.

6. According to mold material, strength calculation or empirical data, determine the thickness and dimensions of mold parts, shape structure and all connections, positioning and guide positions.

7. Determine the structural form of the main forming parts and structural parts.

8. Considering the strength of each part of the mold, calculate the working size of the molded part.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com