Every industry has its own standards, and of course the manhole cover mould is no exception. Don't underestimate the manhole cover mold. Anyone who has experienced the loss and damage of the manhole cover mold knows that it is the guardian of everyone's life. So, what are the standards for composite manhole cover molds?

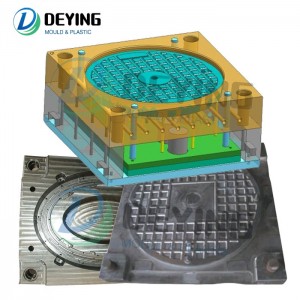

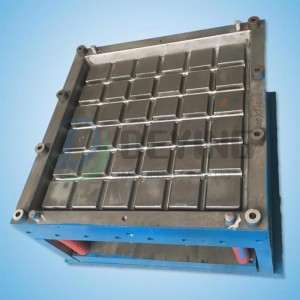

The manhole cover mold must have a certain load-bearing capacity, and it is not easy to be damaged. How many accidents would it cause if it deformed as soon as it was pressed! The manhole cover mold should be anti-noise, which requires the contact occlusal surface of the manhole cover mold and the well ring to directly act on the T-shaped rubber strip to overcome the rigidity and eliminate the noise. The anti-vibration of the manhole cover mold is by setting a U-shaped groove at the stop of the well ring, using T-shaped synthetic rubber strips, embedded in the U-shaped groove, in the process of contact between the manhole cover mold and the well ring, to play a buffering role, reduce Vibration force. Of course, it needs to be slip resistant. The surface of the manhole cover mold uses a raised 3mm pattern to prevent slippage and avoid accidents.

It also needs to prevent displacement. Four rivet bolt holes are reserved in the well circle, which are evenly distributed at 90 degrees. Each set uses 4 ground anchor bolts to avoid displacement due to mechanical rolling during road construction, and Played a certain anti-theft effect. Since cast iron manhole cover molds are often stolen, many safety accidents have occurred, so theft prevention has become one of the standards for composite manhole cover molds.

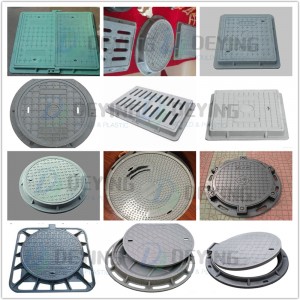

The manhole cover mold of the new composite material is different from the old manhole cover mold. The new product adopts polymer composite material, which is more robust and durable, and has an exquisite appearance, which is conducive to the decoration of the manhole cover and has a great advantage in weight.

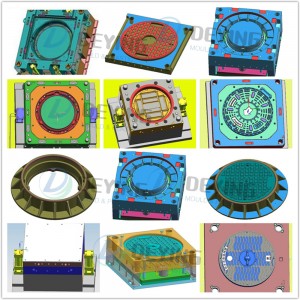

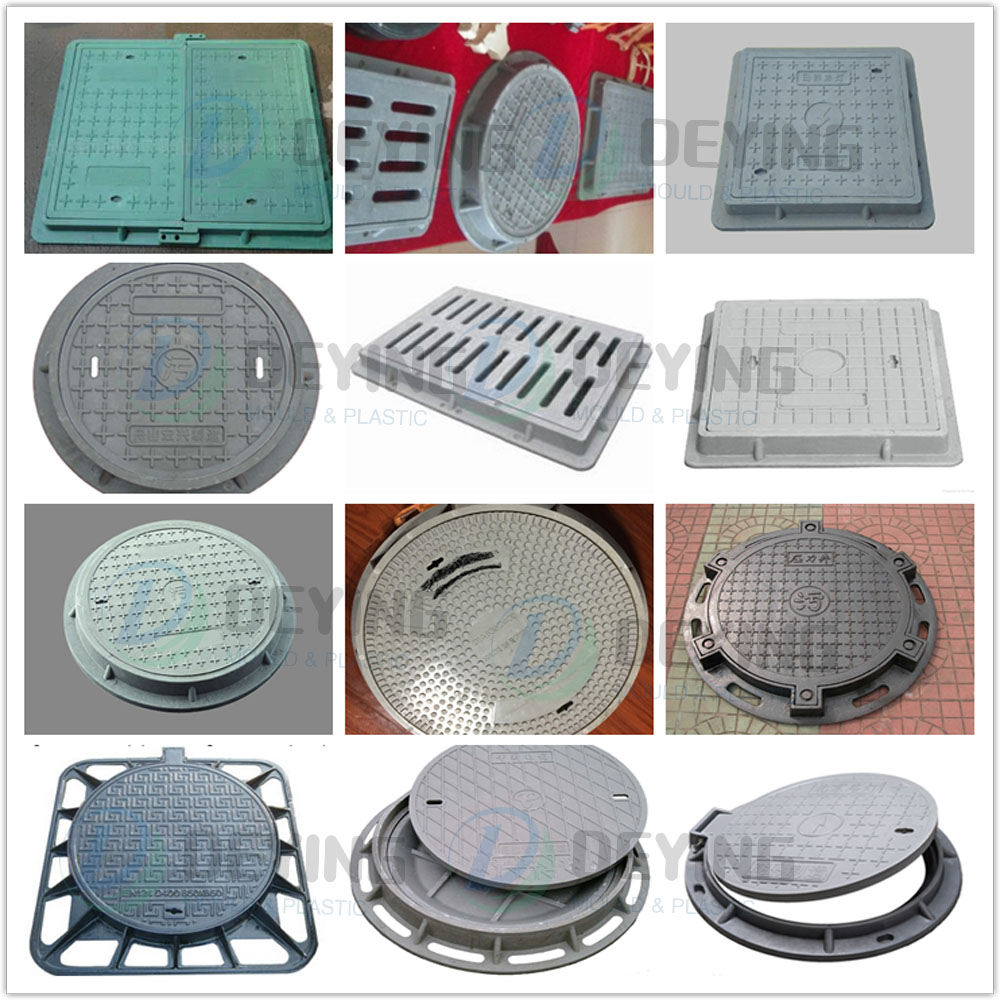

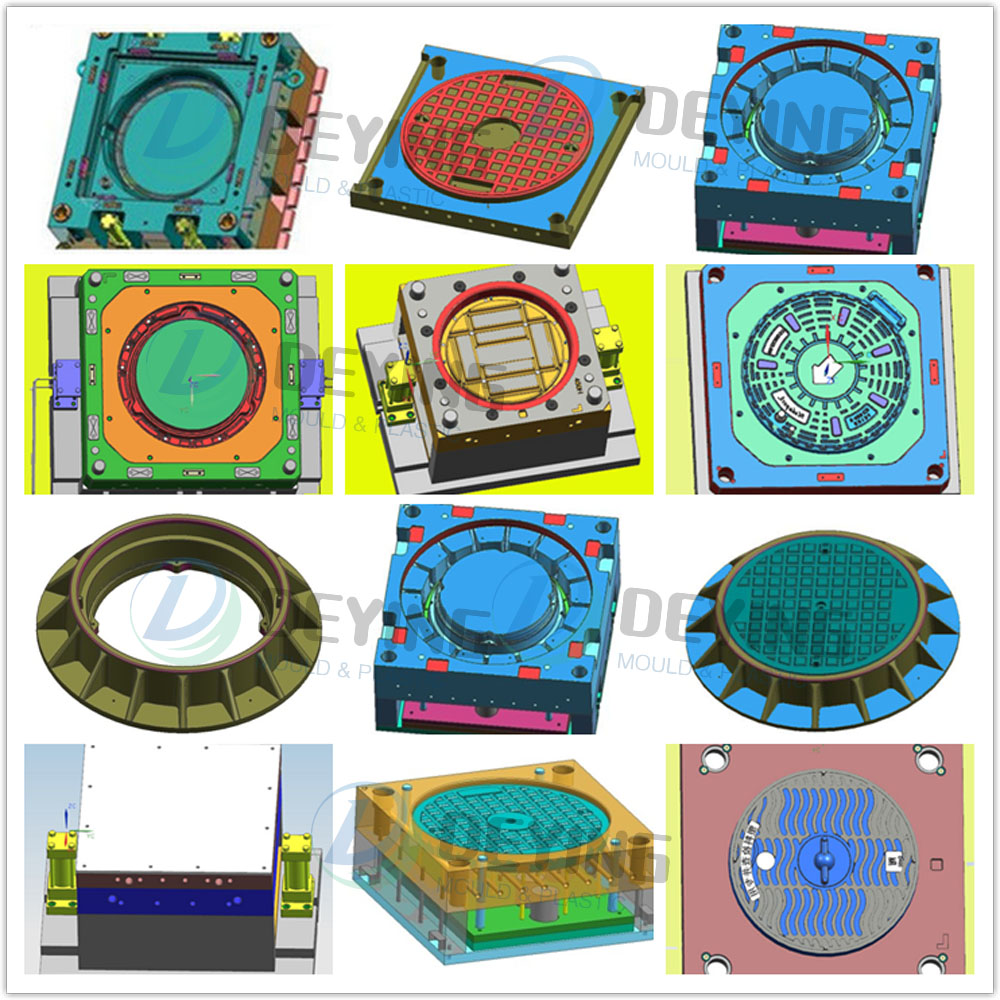

The types of manhole cover molds are: cement round manhole cover mold, county municipal manhole cover mold, inspection manhole cover mold, cement water manhole cover mold

There are two main methods to solve the problem of the manhole cover mold: one is to prevent theft, and the other is to make up the vacancy in time if it is stolen. So, how should we solve the manhole cover problem from these two points? Change the material. The main reason for the frequent theft of manhole covers is that the cast iron manhole covers have an objective recovery value, and there are illegal recycling stations to “sweep the stolen goods”, which makes the theft of manhole covers more and more banned.

Therefore, people should try to use non-metallic materials to make manhole covers, such as polymer composite manhole covers, steel fiber cement manhole covers, magnesite manhole covers, etc. These non-metallic manhole covers do not have the ability to recycle, and indeed play a role in preventing theft.

Install anti-theft devices on existing manhole covers. The manhole cover anti-theft device mainly includes: anti-rotation technique; bolt plugging technique; lock key method; iron chain connection method; hinge connection method; fork joint linkage method.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com