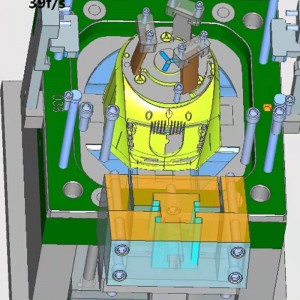

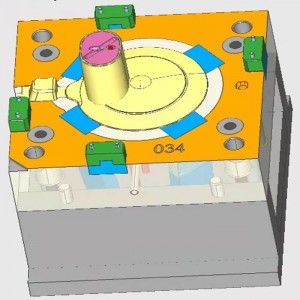

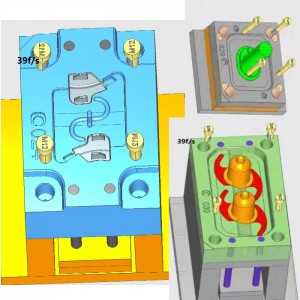

The molding die for the juicer molds includes a bottom mold and a top mold. A cavity is provided on the top surface of the bottom die, a cavity is provided in the center of the bottom wall of the cavity, and four guide protrusions are provided on the inner wall of the cavity. Block, four lifting adjustment blocks are arranged in the cavity, a guide chute is provided on the lower part of the outer side of the lifting adjustment block, a spiral groove is provided on the surface of the lifting adjustment block, and a bearing plate is arranged in the cavity, and the load The top surface of the board is provided with four moving grooves, the bottom surface of the lifting adjustment block is set in the moving groove through an I-shaped slider, and there is a control cylinder between the bottom surface of the carrying plate and the bottom wall of the cavity. The structure of the utility model is set up. Reasonable, reducing the driving structure of the lifting adjustment block, thereby reducing the cost of the mold, and also reducing the difficulty of operation, with good stability in use, strong applicability, and good practicability.

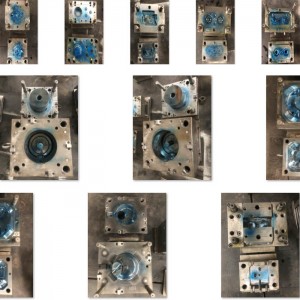

How can I make a mold for an injection molding juicer? First, select the right steel material for the mold base and the mold core cavity. In addition, you must use high-hardness steel as the mold base, and then select the appropriate mold standard parts. A good plastic material filling system requires special hot runner system assistance. Forming, and to ensure that the cooling system achieves the best results. For injection molds, Taizhou DEYING MOLD is a plastic mold manufacturer that specializes in manufacturing and processing injection molds. It also provides plastic product processing services, high-speed milling external processing services, and we pay great attention to the quality of molds.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com