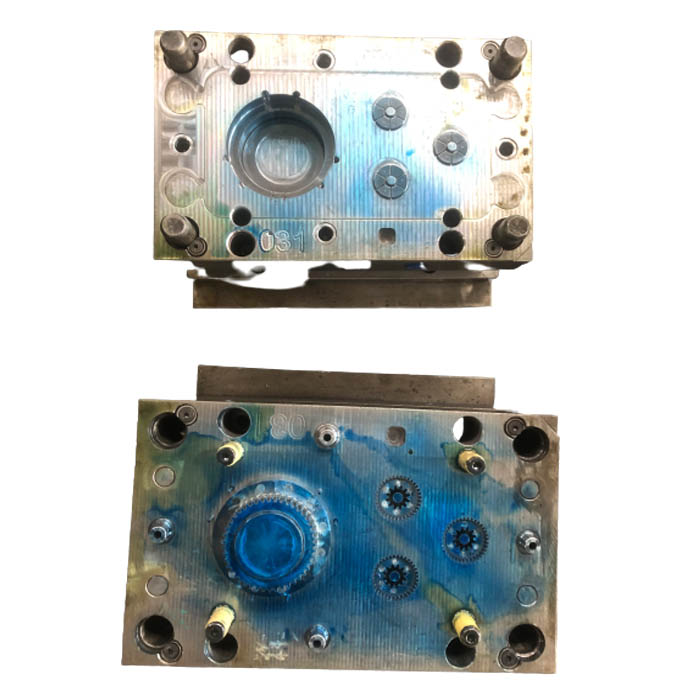

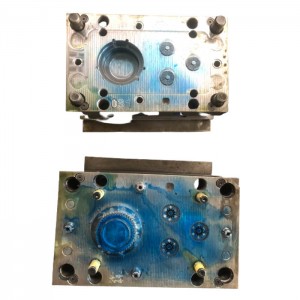

Generally, a complete set of juicer molds include: main machine mold, blade mold, filter knife mold, juice outlet mold, fruit stick mold, juice cup mold, pomace bucket mold, top cover mold.

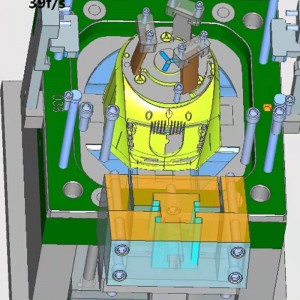

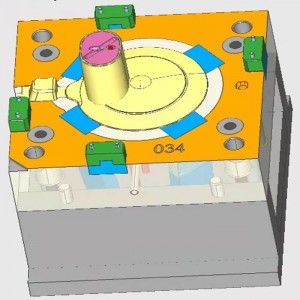

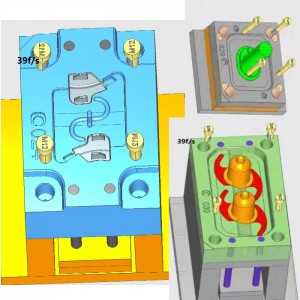

The design of the juicer mold can be completed in about 3 days. The improvement of precision requires that the processing method of each part should be considered clearly in the design process, and the processing method with high precision and low processing cost should be adopted as far as possible.

How can I make a mold for an injection molding juicer? First, select the right steel material for the mold base and the mold core cavity. In addition, you must use high-hardness steel as the mold base, and then select the appropriate mold standard parts. A good plastic material filling system requires special hot runner system assistance. Forming, and to ensure that the cooling system achieves the best results. For injection molds, Taizhou DEYING MOLD is a plastic mold manufacturer that specializes in manufacturing and processing injection molds. It also provides plastic product processing services, high-speed milling external processing services, and we pay great attention to the quality of molds.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

high quality home appliance television shell pl...

-

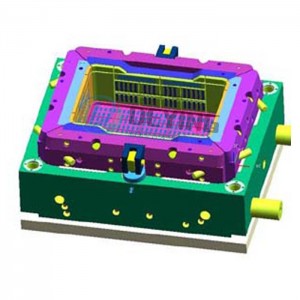

China taizhou stackable plastic injection crate...

-

China taizhou huangyan plastic injection outdoo...

-

Factory Direct Sell Fruit and Vegetable Juicer ...

-

China plastic injection kids Children toy mould...

-

Gallon round plastic injection flowerpot mould ...