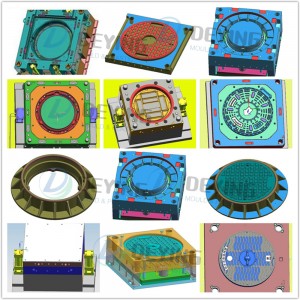

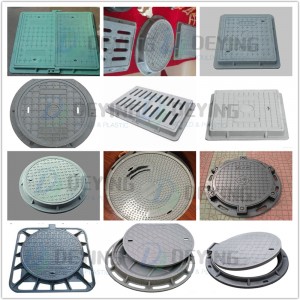

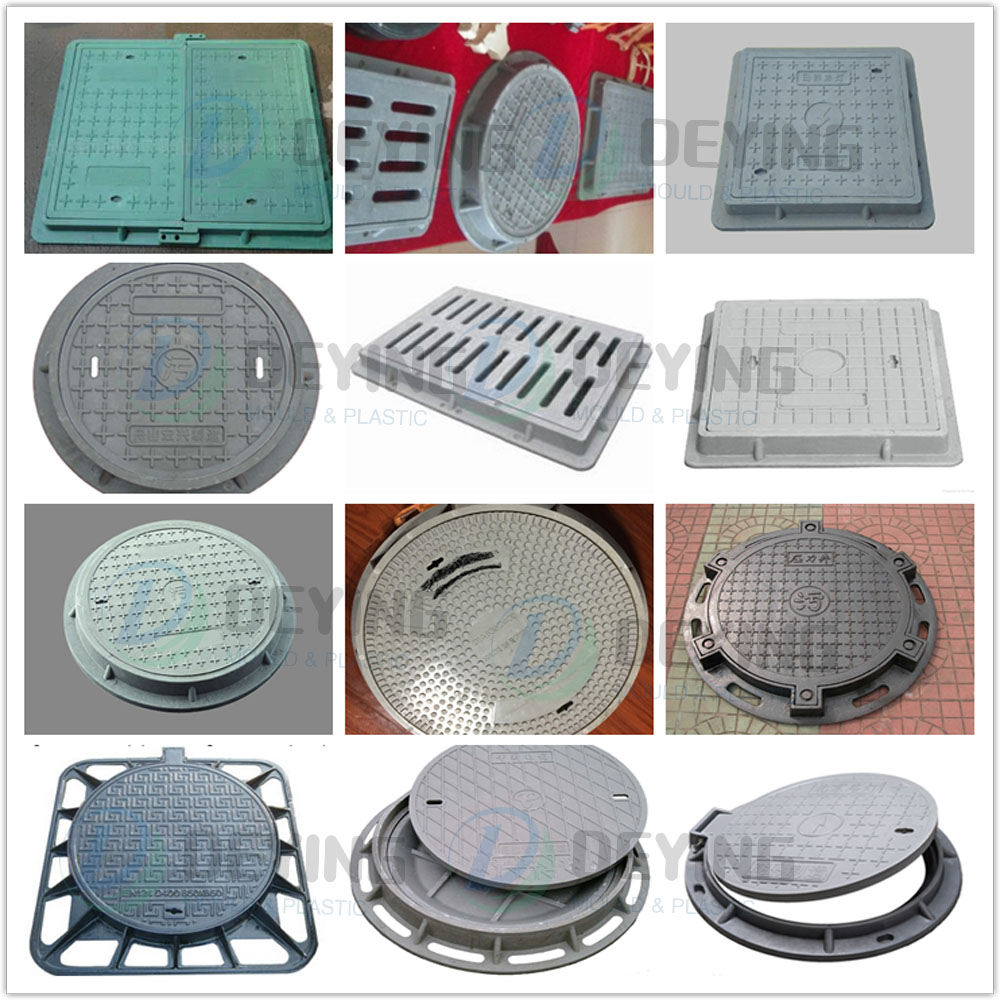

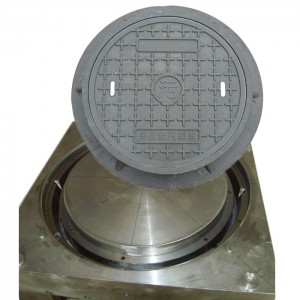

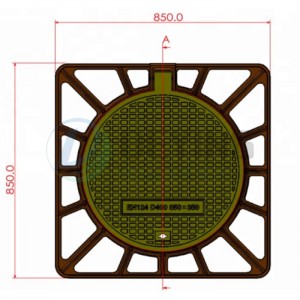

Our country's manhole cover molds industry has basically been based on the internal self-production of enterprises. The tooling industry, which is mainly produced by self-distribution and is attached to product production, has developed into a capital-intensive and technology-intensive equipment manufacturing industry with considerable scale and characteristics of high-tech industries. The design and manufacturing level of molds in my country has been very good. Great improvement. As a technology-based enterprise, it has improved the hardness and wear resistance of the mold, extended the life of the mold, and made the mold have stronger abrasion ability and higher production efficiency.

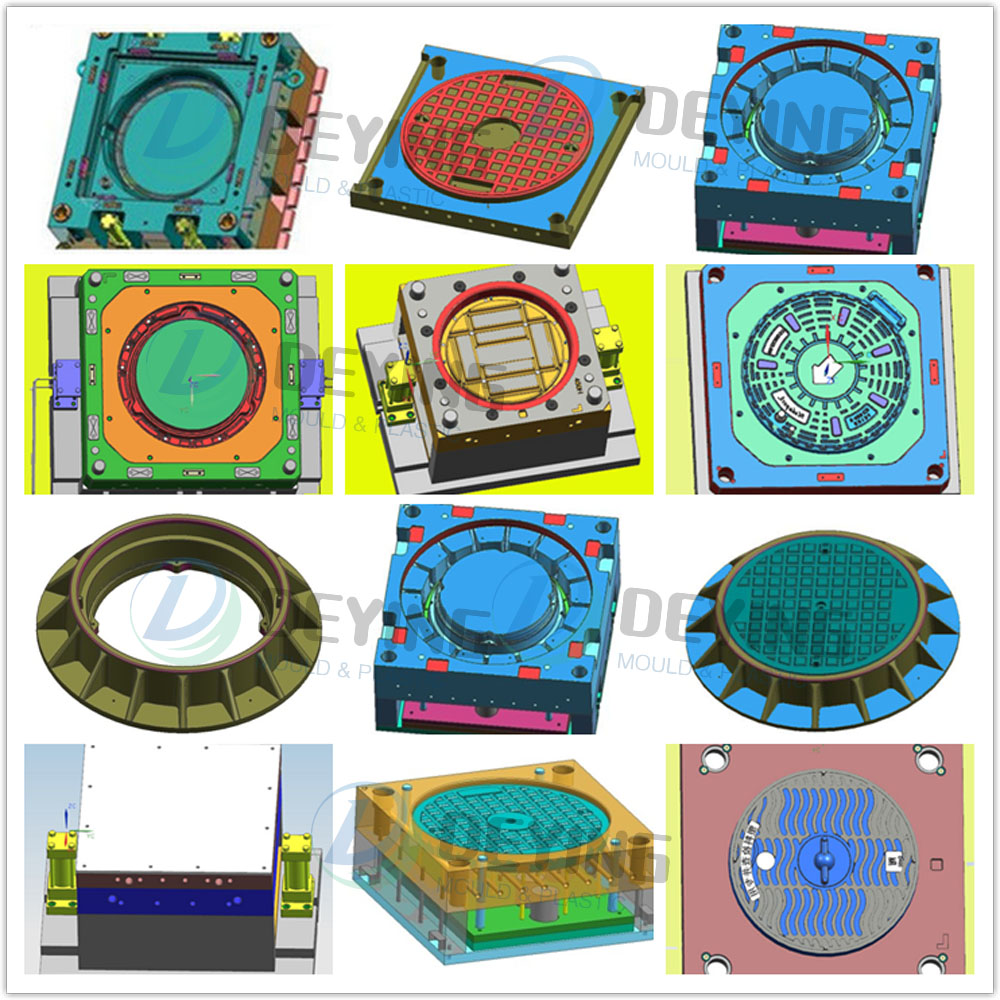

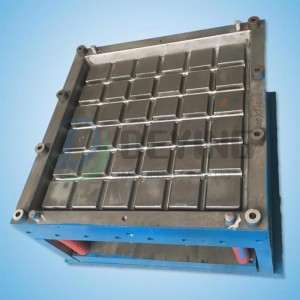

The main advantages of the compression molding process:

1. High production efficiency, easy to realize specialized and automated production;

2. The product has high dimensional accuracy and good repeatability;

3. The surface is smooth and clean without secondary modification;

4. It can form products with complex structure at one time;

5. Because of mass production, the price is relatively low.

The shortcomings of compression molding are that the manufacturing of compression molds is complicated, the investment is relatively large, and the limitation of the press machine, it is suitable for mass production of small and medium composite materials. With the continuous improvement and development of metal processing technology, press manufacturing level and synthetic resin process performance, press tonnage and table size continue to increase, and the molding temperature and pressure of molded materials are relatively reduced, making the size of molded products gradually move toward Large-scale development, and can now produce large-scale automobile parts, bathtubs, integral toilet components, etc.

The composite molds we produce have been effectively optimized, have a longer service life, lower manufacturing costs, and their products can achieve higher precision.

The processing quality of the manhole cover mold mainly includes the processing accuracy and the quality of the galvanic corrosion surface. Due to the many and more complex input and output parameters in the EDM process, the process factors that affect the accuracy of the mold processing involve the manufacturing accuracy of the machine tool itself and the installation of the workpiece. Clamping accuracy, electrode manufacturing and clamping accuracy, electrode loss, discharge gap, machining inclination, etc., among which electrode loss and discharge gap have a greater impact. In the process of EDM of manhole cover molds, pulse discharge will make tool electrodes Loss occurs due to electrical corrosion, so we understand and master the electrode loss law, and then take a variety of measures to minimize the loss of tool electrodes, which can ensure that the mold has higher processing accuracy.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

Factory Produced Plastic Moulds for Manhole Covers

-

Sheet Molding Compound SMC used for Manhole Cov...

-

SMC FRP Manhole Cover Compression Mould from ta...

-

FRP Composite Manhole Cover molds Custom Made

-

SMC BMC manhole cover mould FRP compression com...

-

Mold Factory sell SMC BMC FRP Manhole Cover moulds