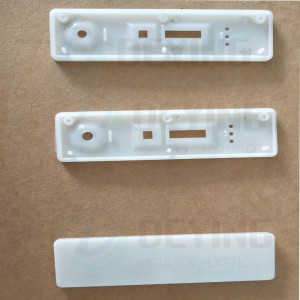

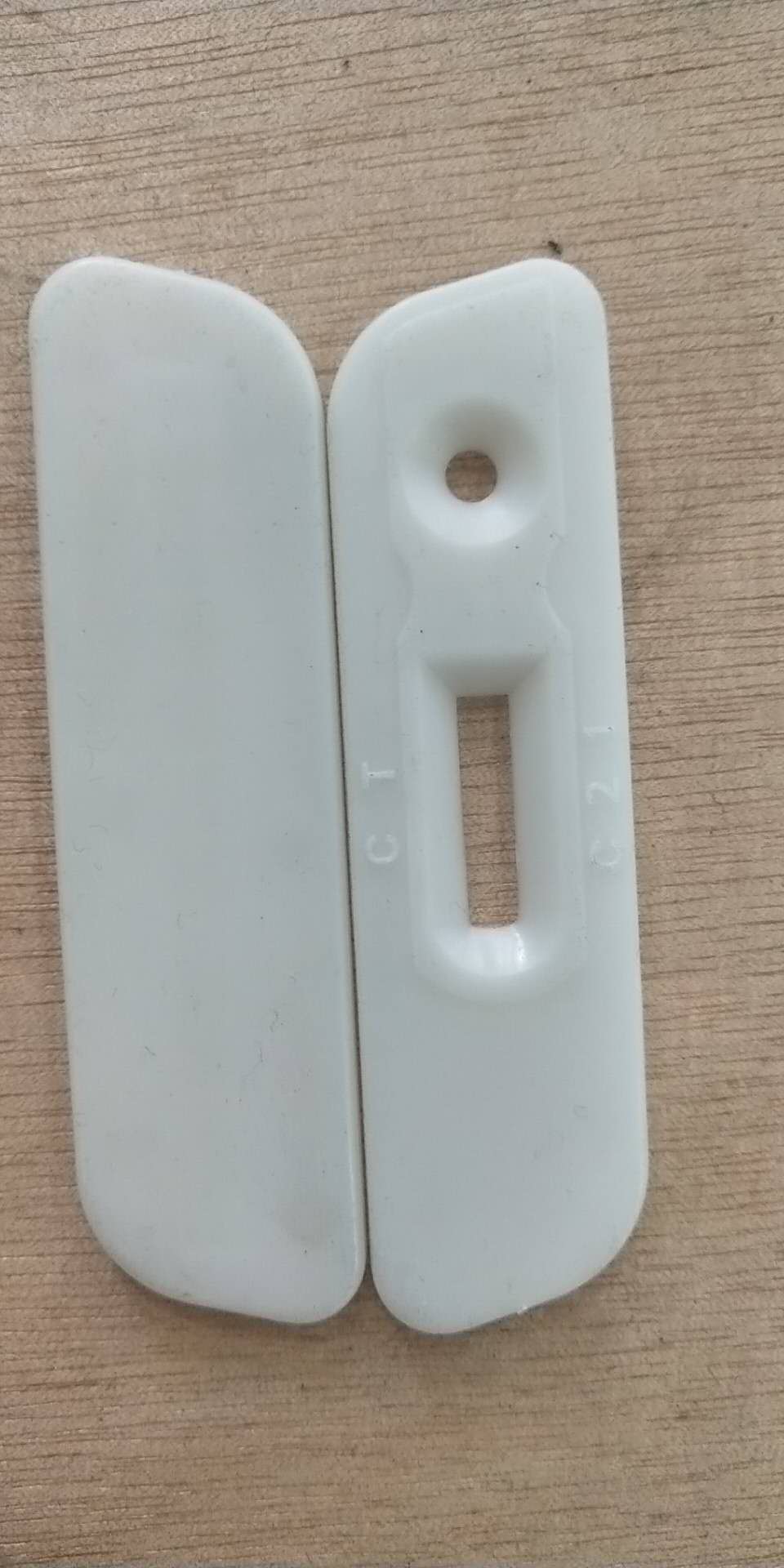

The development of modern medical technology has made plastics widely used in the medical field. From general medicine and pharmaceutical packaging, disposable medical equipment, to multiple precision and high-tech medical meters, surgical instruments, etc., medical plastics have played an important role in improving the level of medical technology. Since medical devices have special requirements for hygiene and safety, smooth surface, and corrosion resistance, the molds of medical plastic products play an important role in the production process of their products. Mold is an important indicator to measure the level of manufacturing of medical plastic products in a country, and to a large extent determines the product quality, efficiency and new product development capabilities. With the gradual improvement of my country's medical and health care system, the demand for disposable medical equipment is increasing rapidly. Put forward higher requirements for mold manufacturing, product production equipment and processes used in medical devices, especially disposable medical devices

Problems that should be paid attention to in the manufacture and production of medical plastic product molds

(1) Strict requirements for mold material selection

Most disposable medical device products use medical grade polyvinyl chloride (PVC) and polycarbonate (PC). Because PVC has better corrosion resistance than steel, and PC has higher hardness, there are strict requirements for the selection of mold materials. It is recommended that domestic mold manufacturers choose Swedish-Shengbai S136H or Japanese Datong NAR-80 steel. These two materials have strong corrosion resistance and high polishing performance.

(2) The heat treatment process controls the hardness

Since the medical grade PVC material has good fluidity, the parting surface is deformed due to the soft material of the mold during the use of the mold, which in turn leads to flash burrs during the injection molding process. Therefore, the hardness of this type of mold material is relatively high. The heat treatment process used in the mold manufacturing process is to perform quenching and tempering treatment after rough machining of the template, and the hardness is controlled at HRC32-36; after the mold trial sample is qualified, the hollow mold, the movable mold, and the core are subjected to vacuum quenching and hardness control In HRC58-620.

(3) The structure design is reasonable and accurate

For transparent products, choose hot runners as much as possible to reduce the traces of materials; when using cold runners, soft PVC should try to shorten the runner size; because disposable medical equipment products are small in size and large in batches, automatic unloading and shearing should be used. In order to ensure production efficiency and quality; disposable medical equipment products have many transparent tubular parts, so when designing, pay attention to the way that the gate feed position and the movable model Z are fixed to avoid improper selection of the gate position and core fixing method , Resulting in uneven material flow during injection molding, resulting in elastic deformation of the core, uneven product or inability to fill the product. For products with elongated tube shapes, proper exhaust methods should be adopted. The inlet manifold should be opened according to the molding conditions of the product. Out of the overflow well, to avoid the difficulty of product forming due to air-locking; the mold cooling system should adopt multiple sets of separate cooling water channels to reasonably control the temperature of the dynamic and fixed molds to control product deformation.

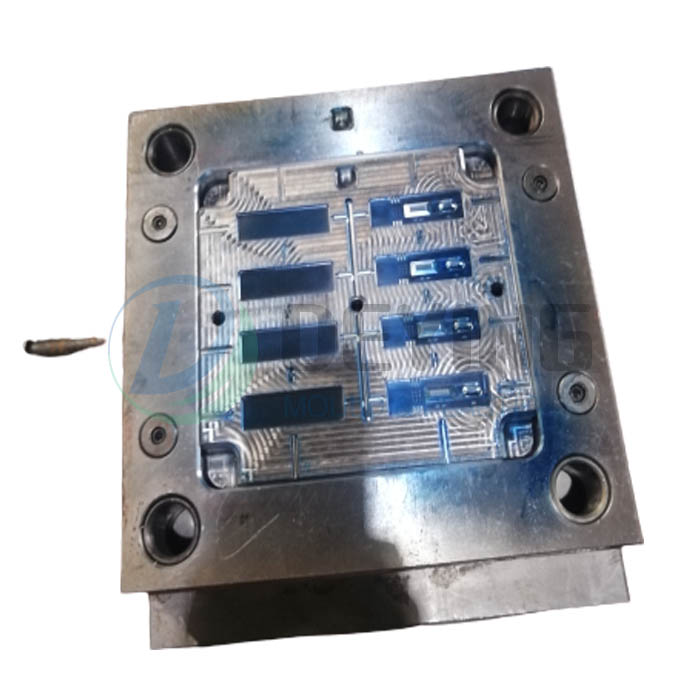

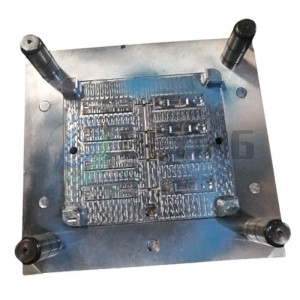

(4) High precision requirements for mold manufacturing

Medical plastic product mold manufacturing process requires tight parting surface, try to ensure mold accuracy through equipment processing methods, parting surface gap should be less than 0.01mm, and the fit gap between push rod and push tube of ejector system should be less than 0.01mm. The push plate ejection structure is adopted, and the push plate should be guaranteed to have a certain degree of hardness.

The fixed mold and movable mold core of transparent products should be polished to ensure that the Ra value is above 0.20. If necessary, liquid polishing can be used.

(5) The selection of injection molding machines and parts is exquisite

The injection molding machine should use a small screw to ensure the accuracy of injection molding, and use an automatic unloading device. The mold can be ejected with gas-assisted unloading; the machine tool is equipped with a manipulator to realize the full-automatic process from product molding to packaging to minimize pollution; The feeding mechanism of the injection molding machine should come to take the closed vacuum feeding, adopt a closed storage tank, arrange the feeding pipe to lead to each injection molding machine, and install the automatic metering vacuum feeding device at the injection molding machine feed port to ensure that the raw materials enter the injection molding machine The front is not contaminated.

(6) The injection molding workshop must be clean and up to standards

The production workshop should be fully enclosed, with high-power air-conditioning ventilators installed to remove harmful gases in time to ensure the constant temperature and clean air in the workshop; during the production process, it is strictly forbidden to use mold release agents and rust removers to ensure that the products are not contaminated PVC products During the production process, it is necessary to strictly control the melting temperature to avoid the decomposition of raw materials to produce harmful gases due to excessively high temperature of the sub-materials and long-term stay in the barrel. The screw and barrel should be cleaned immediately when the machine is shut down to avoid residual raw materials from causing damage to the screw of the injection molding machine; Carry out GMP regulations and strictly follow the IS0 9000 quality management system to ensure that there are no problems at all points in the production process.

-

China Plastic Disposable Test Tube Molding Lab ...

-

medical disposable Laboratory embedding boxes m...

-

Vacuum Blood Collection Tube Injection Mould wi...

-

China taizhou 48cavity vacuum PET blood collect...

-

China Hot Selling High Quality 12 &100 32 ...

-

plastic injection medical flat round 5ml Micro ...