meltblown spinneret mold non-woven Fabric mold melt blown die meltblown mold melt-blown spinneret mould Taizhou Huangyan

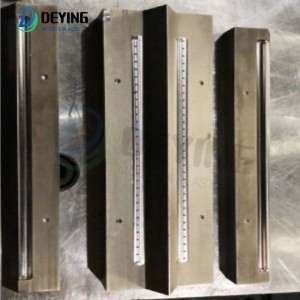

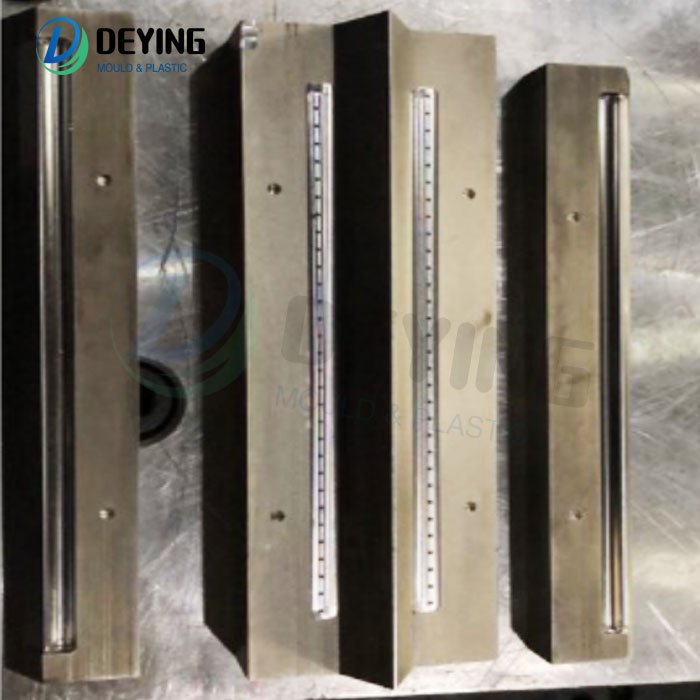

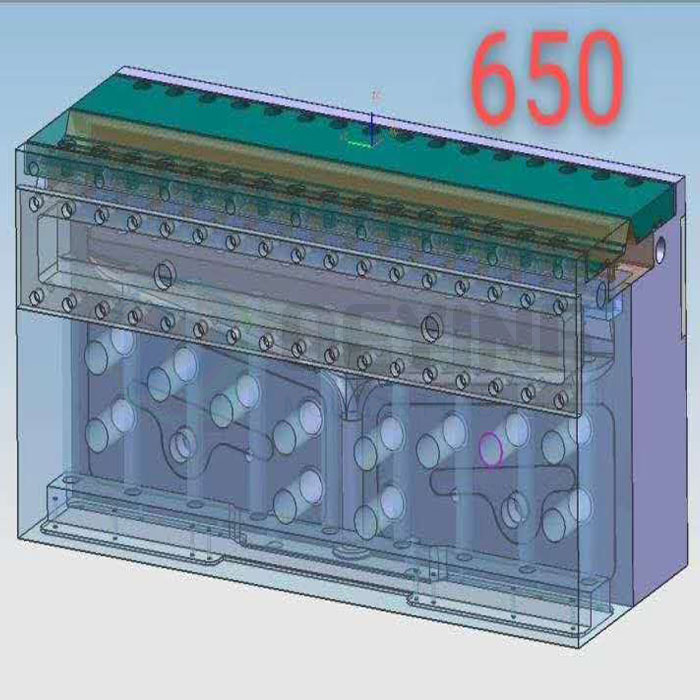

Each set includes: air knives 2 pcs, spinning board1pc, distribution plate 1pc, deflector 1pc, Side plates 2pcs, feed connector 1pc, Intake connector 2pcs and aluminum washers 3pcs. The screws are all 12.9 high strength bolts. 0.3mm hole melt-blown spinnerette.

Melt-Blown Spinneret for Spinning Production Line for Mask Making

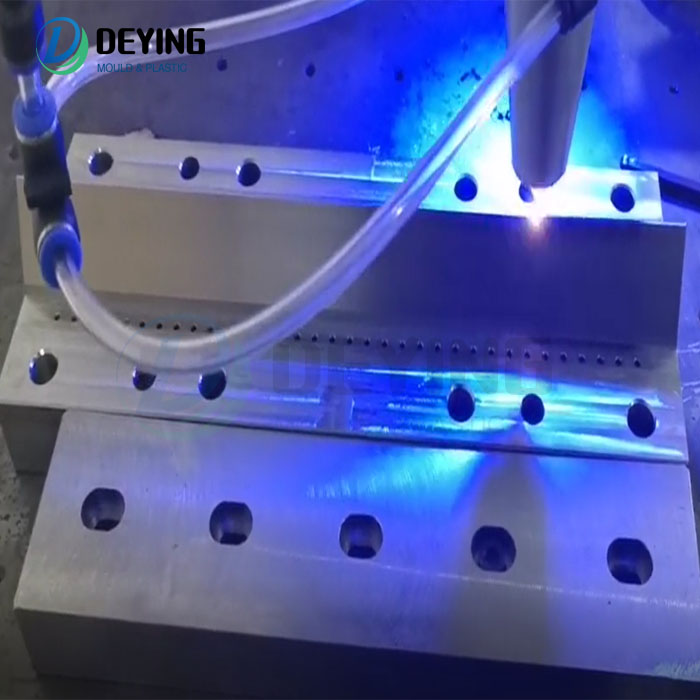

This spinneret plate for meltblown nonwoven fabric mask making machine. It is the high precision melt blown spinneret mold. The small drilled holes for polymer feeding are drilled by high precision CNC small hole EDM popping machine.

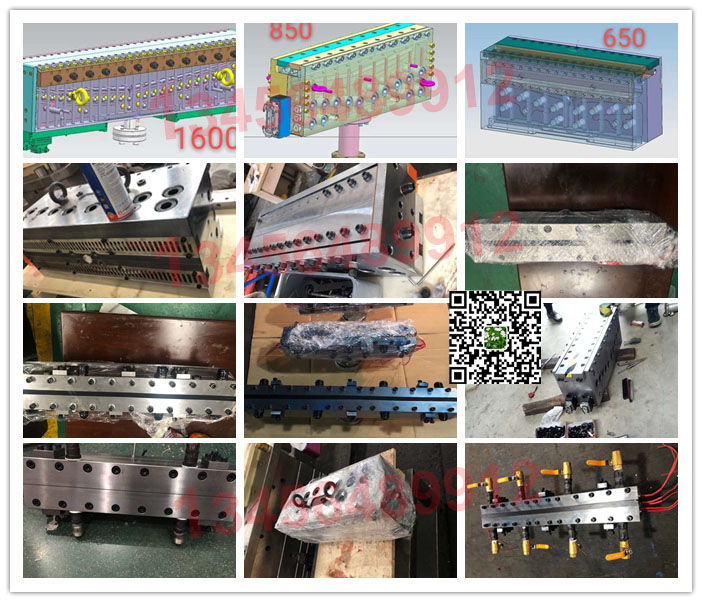

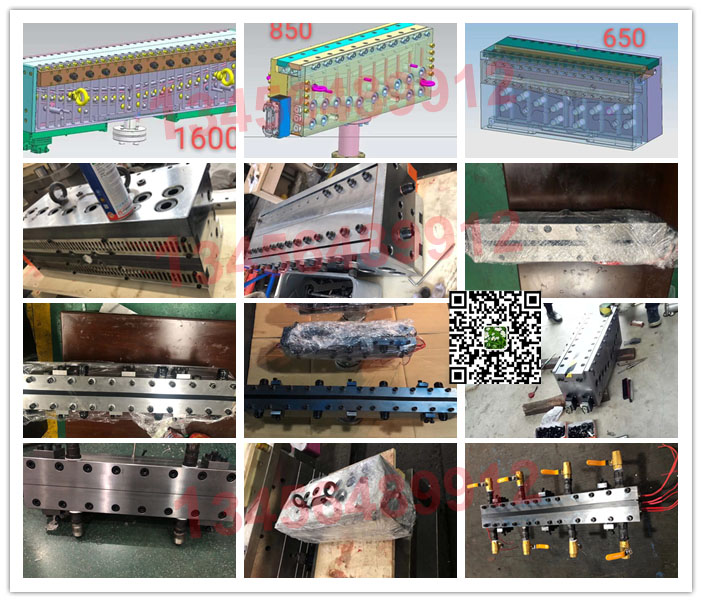

Melt blown spinneret size:

Length 300mm and 450mm,650mm,850mm are available

Feeding hole: drilled with 0.2mm diameter electrode tube , finished diameter during 0.25-0.26mm.

Melt-blown nonwoven fabric is made by entangling fibers while extruded material from the spinneret in the same time blowing hot air. The common application is face masks, industrial filters, etc.

Infect by CORNA-19 epidemic, masks are very limited, no matter the FFP3, FFP2, N95, KN95 KN90, surgical mask; medical mask, ordinary masks/respirator, all masks are lack.

Mask making machines are working every day every 24 hours, the consumables and spare parts in stock are very necessary to keep the machine running.

The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments, integrated with the conversion of the filaments into a random laid nonwoven fabric. For more information about Melt-Blown process, welcome to check: https://www.sciencedirect.com/topics/engineering/melt-blown-process

China Melt Blown Die Head Suppliers

Melt-blown fabrics have generally the same applications as other nonwoven products. The main uses of melt-blown nonwovens and other innovative approaches are as follows.

2. Hole number encryption, more output, energy efficient.

3. L/D( Length to diameter ratio) of 1:15, not easy to deform and long service life, reducing replacement costs

4. Automated machining center production, spinneret detail is perfect.

5. Innovative static mixer design for more uniform discharge.

2):Hole size Can be produced ≥0.06mm(0.0024 inch)

3):Tolerance: ±0.002(0.000078inch)

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com