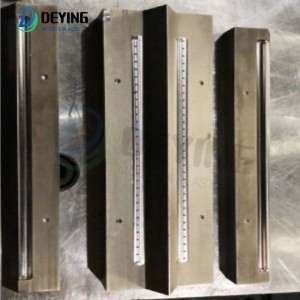

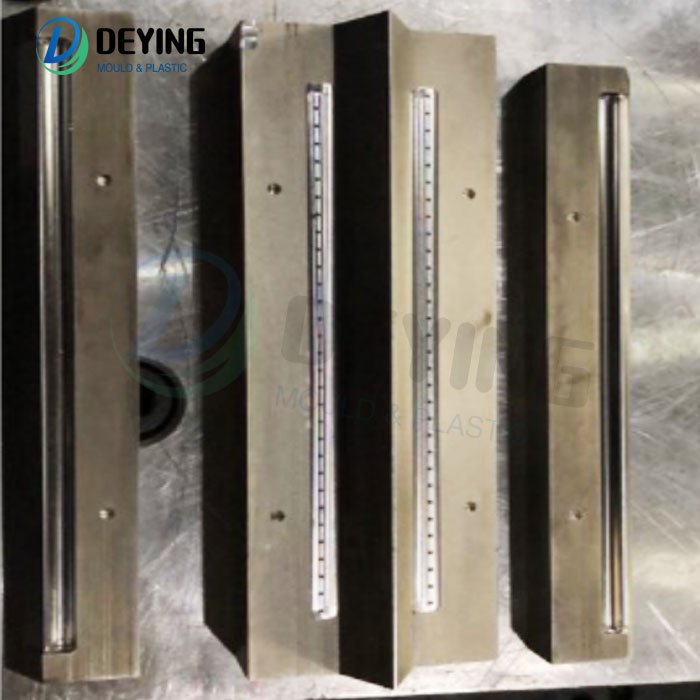

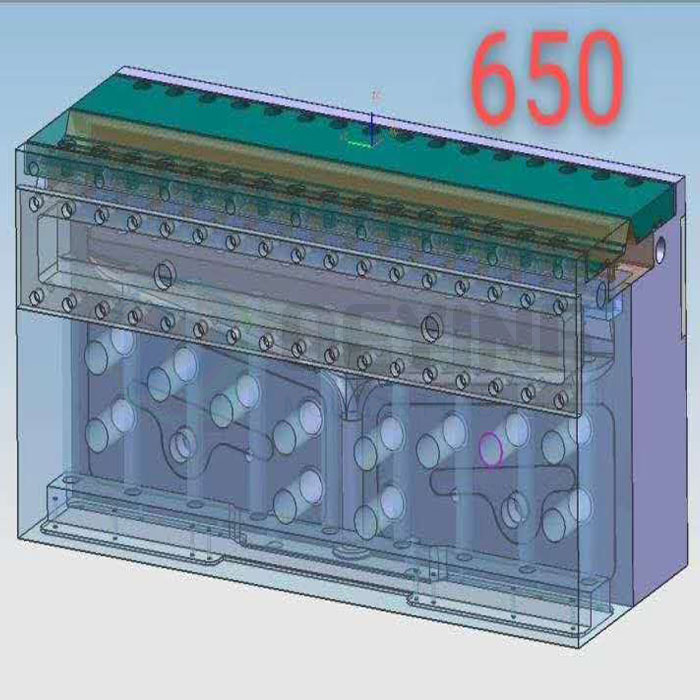

Each set includes: air knives 2 pcs, spinning board1pc, distribution plate 1pc, deflector 1pc, Side plates 2pcs, feed connector 1pc, Intake connector 2pcs and aluminum washers 3pcs. The screws are all 12.9 high strength bolts. 0.3mm hole melt-blown spinnerette

Accuracy of Spinneret

Surface Roughness of Spinneret Hole(ISO)

countersink N5-N7

counterbore N3-N6

transition angle N2-N6

capillary N1-N3

mirror finish by buffing N1

mat finish by lapping N2-N4

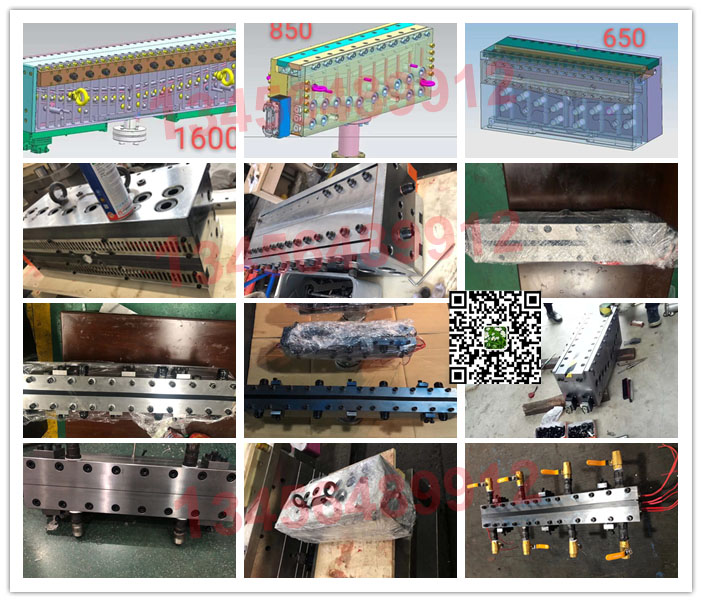

800mm, 1200mm, 1600mm Fleece Spray Die 1600 Mask Fleece Die N95 Fleece Spray Die

1600 velvet-sprayed cloth die head, double runner design, N95 standard

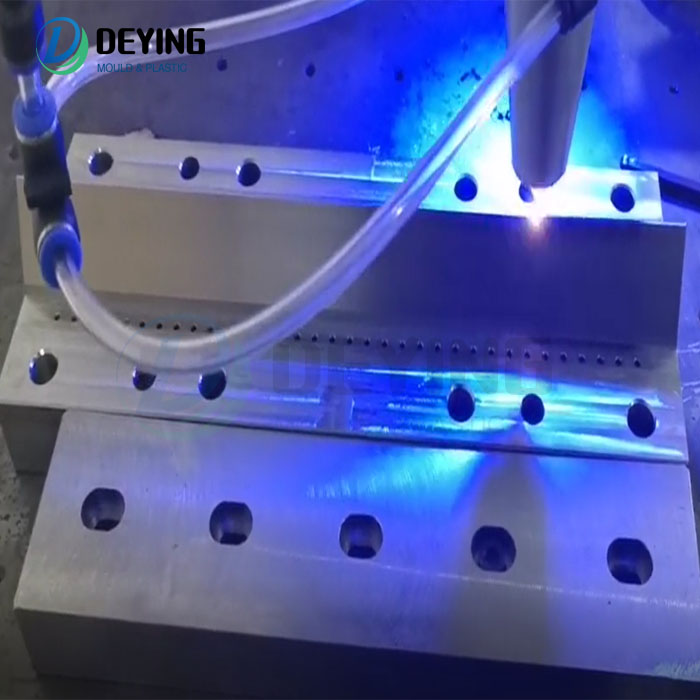

Other models are welcome to customize with pictures. High-speed milling, FANUC 20000 rpm professional drilling and tapping machining

Melt spin spinneret in spinning line

The melt blown process, and its variants, is the only large-scale commercial process that

is presently being used to directly produce melt spun fibers with diameters in the submicron range without splitting or chemically

dissolving away polymer. It is a nonwovens operation that directly creates fabrics of various widths and thicknesses on large rolls.

The melt blown technologies.

China Melt Blown Die Head Suppliers

Melt-blown fabrics have generally the same applications as other nonwoven products. The main uses of melt-blown nonwovens and other innovative approaches are as follows.

2. Hole number encryption, more output, energy efficient.

3. L/D( Length to diameter ratio) of 1:15, not easy to deform and long service life, reducing replacement costs

4. Automated machining center production, spinneret detail is perfect.

5. Innovative static mixer design for more uniform discharge.

2):Hole size Can be produced ≥0.06mm(0.0024 inch)

3):Tolerance: ±0.002(0.000078inch)

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com