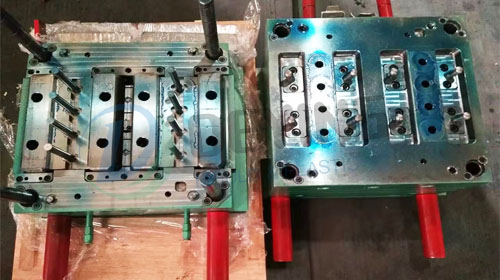

This Medical Test tube mold for UK market,which is made by S136 mold steel with YUDO hot runner.

It’s interchange insert for 2 type of tube.

Medical mold making requirements experience

Medical molds are very high demanding molds. The product inspection standards are extremely high. In addition to high-precision machining, the use of this product is more important, and the national inspection standards of the Quality Supervision Bureau must be understood. Some products require clinical testing to determine whether they are qualified or not.

1.The main difficulty of the needle is that the core size accuracy of the needle tip is not well controlled. Even the equipment with high processing precision may not be processed in place. The size of the Luer joint at the bottom is designed according to the slope of 6:100. Standard test, the actual accuracy may be 0.005-0.01mm, otherwise there will be water leakage, and the core processing scrap rate is very high.

2.The mold steel material is selected, the mold should be selected with high hardness, and the steel material above HRC 35° is most suitable. Generally, nak80/S136 steel material is selected. The mold has small thermal deformation and excellent discharge.

3.The control of the processing precision is particularly important ,because the needle product of the puncturing device is very small, the smallest hole has a diameter of only 1 mm, and the concentricity of the core is also ensured, which is very accurate for testing the precision of the mold processing personnel and the processing equipment. We chose imported high-speed lathes when selecting processing equipment, and tried to use equipment that was not used for 5 years, as to the actual machining accuracy of equipment that has been out of the old years has deviated, which will directly affect the molding of the products. Needle to use the copper electrode is not easy to wear, high-speed carved in place after the mold and then use the mirror electric spark to hit the position (here should pay attention to the processing spark gap control)

4.The choice of gate, generally this product will use multi-cavity design structure, the mold uses hot runner with sub-gate, because the gate is on the inclined surface, it is easy to appear the gate problem, this time the EDM of the sub gate Especially important, the spark gap should be within 0.01

Post time: Nov-19-2019