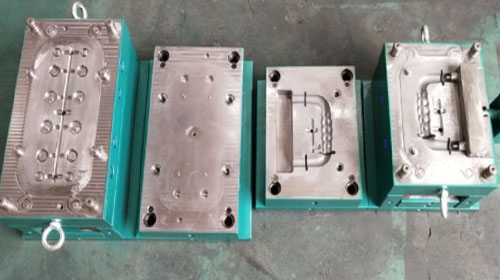

Plastic injection handle mould exported to Ecuador

This handle mold used for Bulletproof/ ballistic shield ,It consists of 3 parts, a total of 2 molds.

Mold 1 handle molding:one cavity cold runner P20 steel.

Mold 2 cover moulding:12 cavities cold runner P20 steel.

Product material:ABS and PP

Production time:45 days.

Deying Mold is only for you, any inquiry, please contact.

With the development of the plastic processing industry, people’s lives are more and more inseparable from plastic products. A wide variety of plastic products also bring great convenience to our lives. Handle mold is also an indispensable product in our lives.

The accuracy of the mold is one of the important factors that affect the accuracy of the plastic molded parts.The accuracy of the mold should meet the following technical requirements during manufacturing:

(1) All the parts that make up the plastic mold, in the material processing precision and heat treatment

Quality and other aspects should meet the requirements of the corresponding drawings.

(2) The parts that make up the mold base should meet the specified processing requirements.The formwork should move freely and meet the required parallelism and perpendicularity requirements

(3) The function of the mold must meet the design requirements

(4) In order to identify the quality of plastic molded parts, the assembled mold must be

Try the mold under the production conditions, and repair according to the problems of the test mold until the qualified

So far as molded parts.

Post time: Jul-14-2020