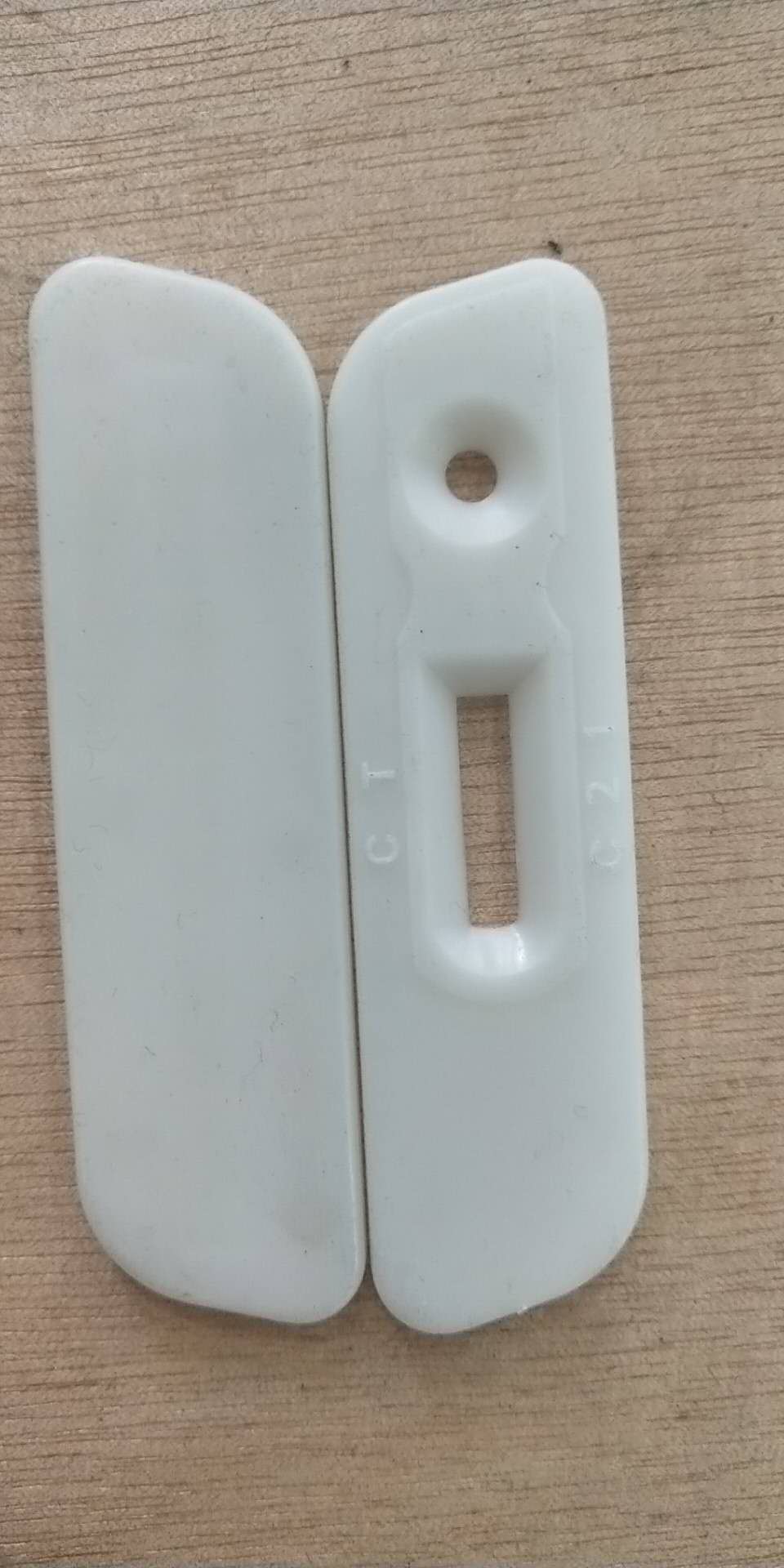

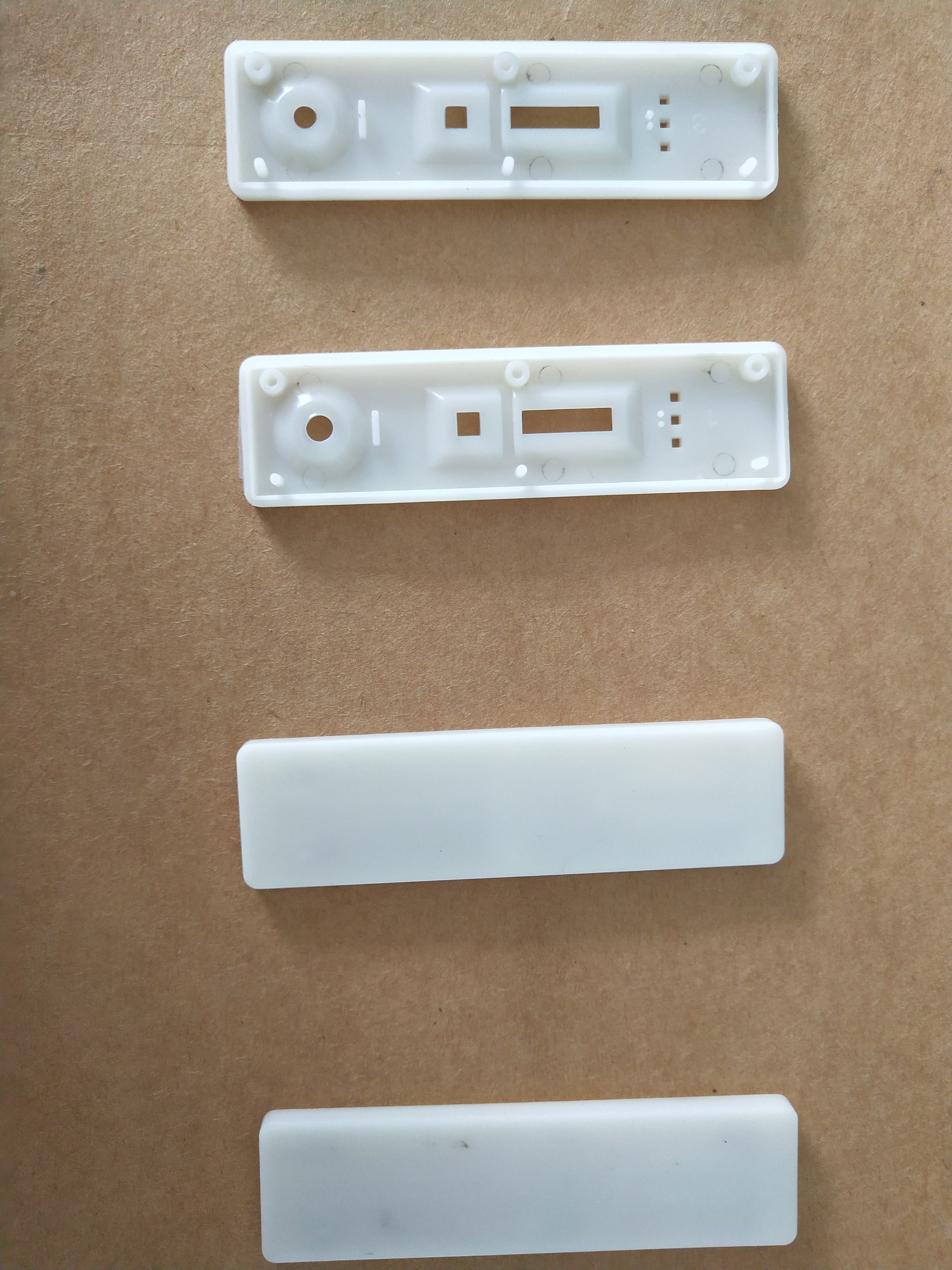

Medical mould test kits injection mold to Pakistan

Medical kits are generally made of pp materials, which have very good chemical resistance, odorless and non-toxic, can be autoclaved, have good heat resistance, and are not easily deformed. They are widely used in the pharmaceutical industry, and the production of kits Generally need to be made by injection mold.

However, the existing injection molds for the production of kits are generally prone to leave a gap between the upper mold and the lower mold, making it easy to leave burrs between the upper mold and the lower mold on the kit, resulting in the need to perform surface treatment after the kit is produced. Surface treatment makes the production quality of the kit not conducive to improvement

Matters needing attention in medical injection molds

For products produced by medical injection molds, he has to deal with human health, so people have very strict requirements on him. Mold designers must be familiar with the international standards of medical products. Medical molds generally have high requirements for mold life. The requirements for die steel are also very high, so good steel must be used. Because medical molds have high requirements for product finish, they also have high requirements for output and accuracy of medical products! It has a service life of at least 3 million mold cycles. For medical products, the design structure must be reasonable, and the equipment precision and cleanliness of the injection molding machine have very high requirements, because it must be matched with the medical injection mold in order to Good medical products

Post time: Aug-21-2020