1.Injection Mold

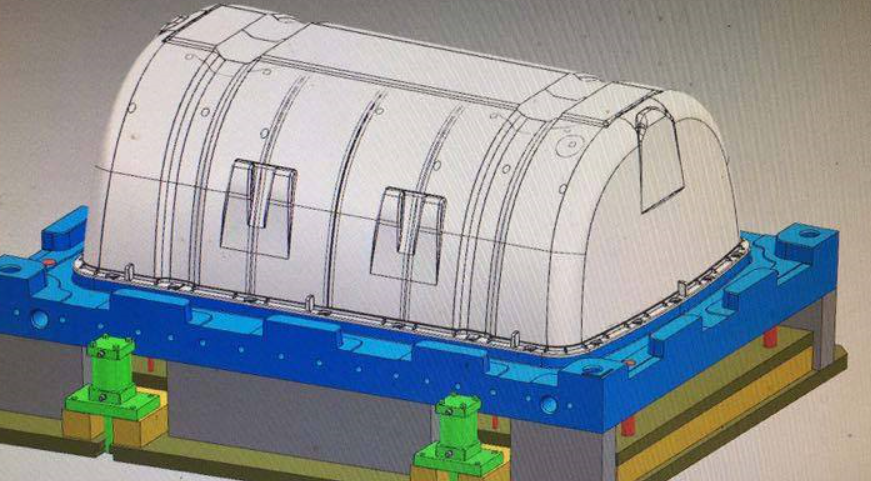

Injection molds are parts that give plastics shape and size during molding.

Although the structure of the mold may vary widely depending on the variety and performance of plastics, the shape and structure of plastic products, and the type of injection machine, the basic structure is the same.

According to the molding characteristics, injection molds are divided into two types: thermoset plastic molds and thermoplastic plastic molds;

According to the molding process, it is divided into plastic transfer mold, blow mold, casting mold, thermoforming mold, hot compression mold (compression mold), injection mold, etc. Among them, the hot compression mold can be divided into overflow type, half type and flash Three types of overflow and non-overflow;

Injection molds can be divided into cold runner molds and hot runner molds by the pouring system;

It can be divided into mobile and fixed types according to loading and unloading methods.

The classification of molds is also differentiated according to different processing techniques. The injection mold is to inject molten plastic into the cavity of the mold at a certain speed and pressure. After the plastic is cooled, open the mold to take out the molded injection product.

2.Compression Moul

Compression mold is simply referred to as compression mold. The plastic material is directly added to the open mold cavity, and the mold is closed. The plastic is heated and pressured to flow and fill the cavity, and then the product is chemically crosslinked or physically cooled to make the product. Hardening.Deying Mold good at produce compression septic tank mold.

The compression mold uses a heated mold to heat and press the plastic sheet into a shape, then opens the mold, takes out the formed product, and puts it into cold water for cooling.

Compression molding is an important technical process in molding processing. It has a wide range of applications in industrial production and industrial processing, and plays an important role in people’s lives.

Generally, powdery, granular, agglomerate, flake, or even a preform similar to the product is first placed in the cavity of a heated mold, and then the mold is closed and pressurized to form and cure or cure The product obtained by demolding (see picture), this method is particularly suitable for the molding process of thermosetting plastics (see thermosetting resins). Disadvantages are long production cycles, low efficiency, and poor product dimensional accuracy

Post time: Mar-22-2020