-

main advantages of compression molding process

The main advantages of the compression molding process: 1. High production efficiency, easy to realize specialized and automated production; 2. The product has high dimensional accuracy and good repeatability; 3. The surface is smooth and clean without secondary modifica...Read more -

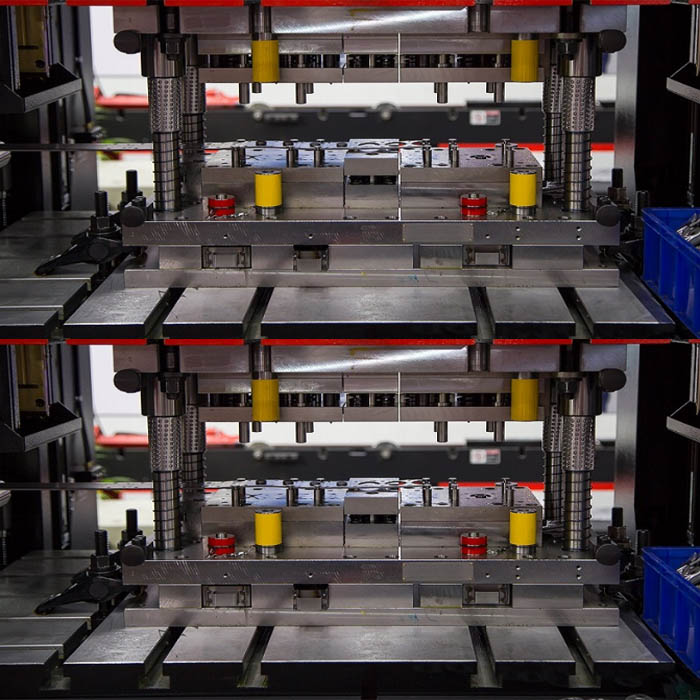

Professional manufacturer of compression molds from Taizhou DEYING

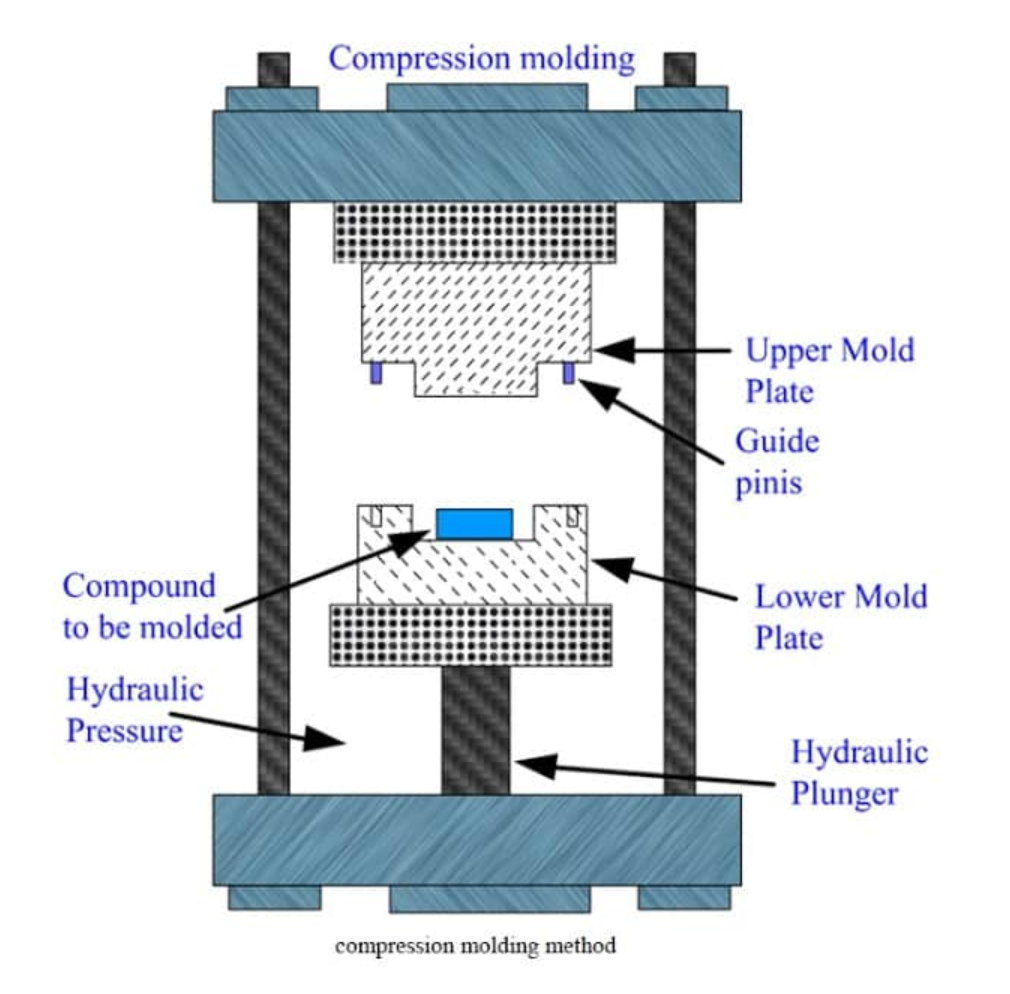

Compression molding-Taizhou DEYING, a professional manufacturer of compression molds, mold compression molding is an operation that first puts powdery, granular or fibrous plastic into the mold cavity at the molding temperature, then closes the mold and pressurizes it to...Read more -

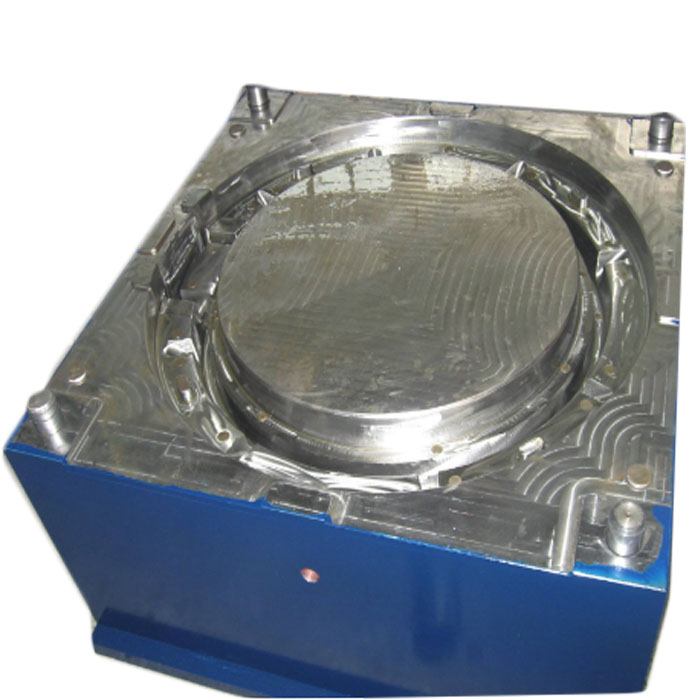

fiber glass manhole cover compression mould introduction

The types of manhole cover molds are: cement round manhole cover mold, county municipal manhole cover mold, inspection manhole cover mold, cement water manhole cover mold Mold production of FRP manhole cover moulds The glass f...Read more -

SMC BMC mold application industry products and characteristics

SMC is sheet molding compound. The main raw materials of SMC are composed of GF (special yarn), UP (unsaturated resin), low shrinkage additives, MD (filler) and various additives. SMC has the advantages of superior corrosion resistance, soft quality, easy engineering des...Read more -

How to prevent the aging of manhole cover mold?

The compression manhole cover moldings is not made of ordinary plastic. It is made of high-strength anti-aging engineering polypropylene. The product has very strong toughness and can withstand a weight of 200 kg. It can also ensure that it will not be deformed for a lon...Read more -

The prospects of the composite mold market are promising

Composite materials are made up of two or more materials with different properties through physical or chemical methods to form materials with new properties. With the broadening of the application field of composite materials, the composite material molding industry has...Read more -

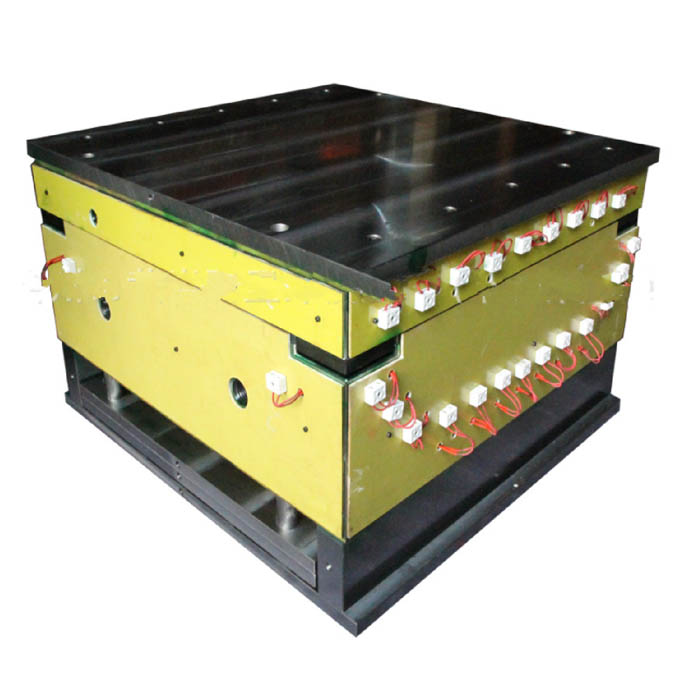

compression molding Hot press forming mold factory

Many companies in the aerospace, automotive, construction, and electronics industries are using composite materials to reinforce plastic parts or replace metal stamping parts. The composite material can be glass, thermoplastic, phenolic or epoxy. When thermosetting resin...Read more -

Talking about composite compression molding

Over the years, compression molding has been used to form various products, such as body panels, household appliances, and industrial fixtures. Metal stamping dies are heavy and expensive to produce. Composite materials provide a cost-effective way for anyone to mass-pro...Read more -

Wide application of carbon fiber molds in automobile manufacturing

Compared with other traditional materials, carbon fiber has obvious advantages, such as high specific modulus and specific strength, good mechanical properties of manufactured components, strong designability and high safety, integration of parts and components, and deve...Read more -

What is carbon fiber molds?

Many parts are made of carbon fiber compression molds, such as some parts of automobiles Fiber is a polymer, also known as graphite fiber, because it is made of organic fibers such as flake graphite crystallites stacked along the axial direction of the fiber. It is a mic...Read more -

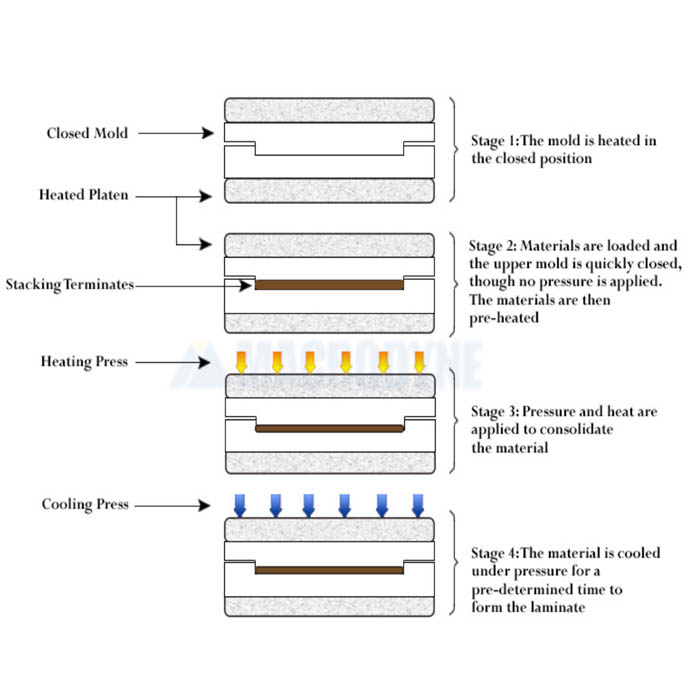

The trend of heat compression forming molds

With the development of lightweight, when reducing the weight of components, it is also necessary to meet the requirements of high strength. Hot press molding is one way to meet these requirements. What is a hot press forming mold? Hot press molding is a special plastic ...Read more -

How do carbon fiber molds undergo compression molding?

Carbon fiber is a high-performance structural material with many performance advantages, such as light weight, high strength, high temperature resistance and corrosion resistance. Therefore, carbon fiber has been used in aerospace, medical equipment, rail transit, automo...Read more -

What is heat compression forming mold ?

The molding process is a new type of composite material molding method, and good product quality is guaranteed by a stable mold. The temperature of the mold directly affects the molding quality and productivity of the finished product, so the temperature needs to be stri...Read more -

Advantages and Disadvantages for Compression molding Process

Compression molding Process- Advantages and Disadvantages Compression molding is a well known technique to develop variety of composite products. It is a closed molding process with high pressure application. Heat and pressure is applied as per the requirement of compos...Read more -

Compression molding process parameters

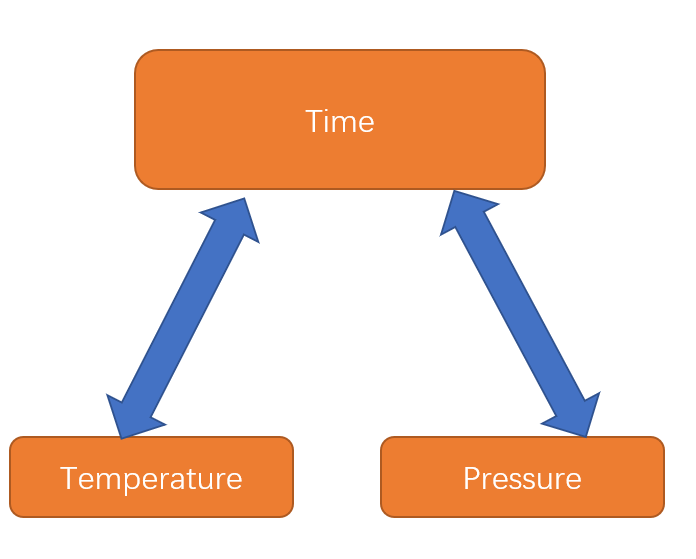

The quality and performance of plastic parts is not only affected by the properties of plastic raw materials and the size of the mold structure, but also related to the formulation and control of the molding process parameters. This is the three elements of molding often...Read more -

Some things you need to know about the molding process

This article will introduce you some related molding methods, main molding principles and control factors 1. Molding method Carbon fiber is a fiber material, so the formation process of carbon fiber is the formation of fiber. The fiber forming process is a process of pla...Read more -

three elements of the compression molding process

The three elements of the molding process are: time, pressure, and temperature. The molding temperature is the mold temperature specified during molding. This process parameter determines the heat transfer conditions of the mold to the material in the cavity, and has a d...Read more -

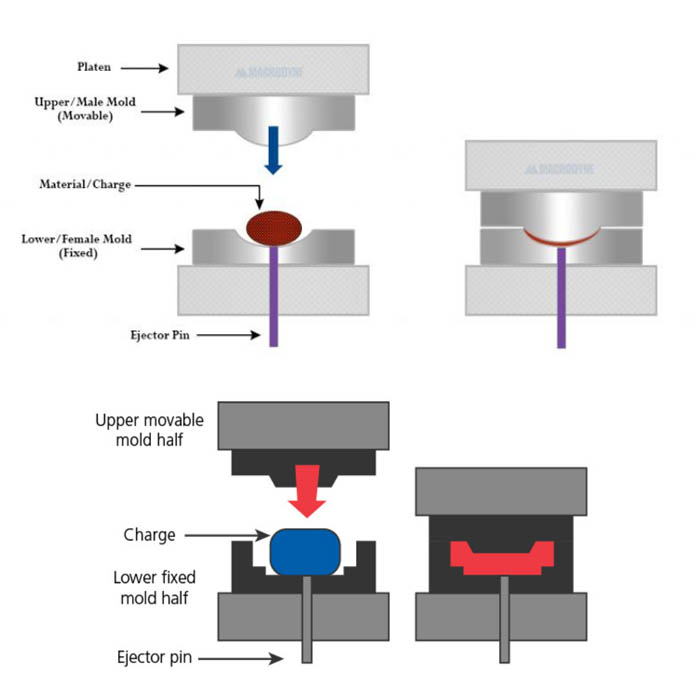

How Does Compression Molding Work?

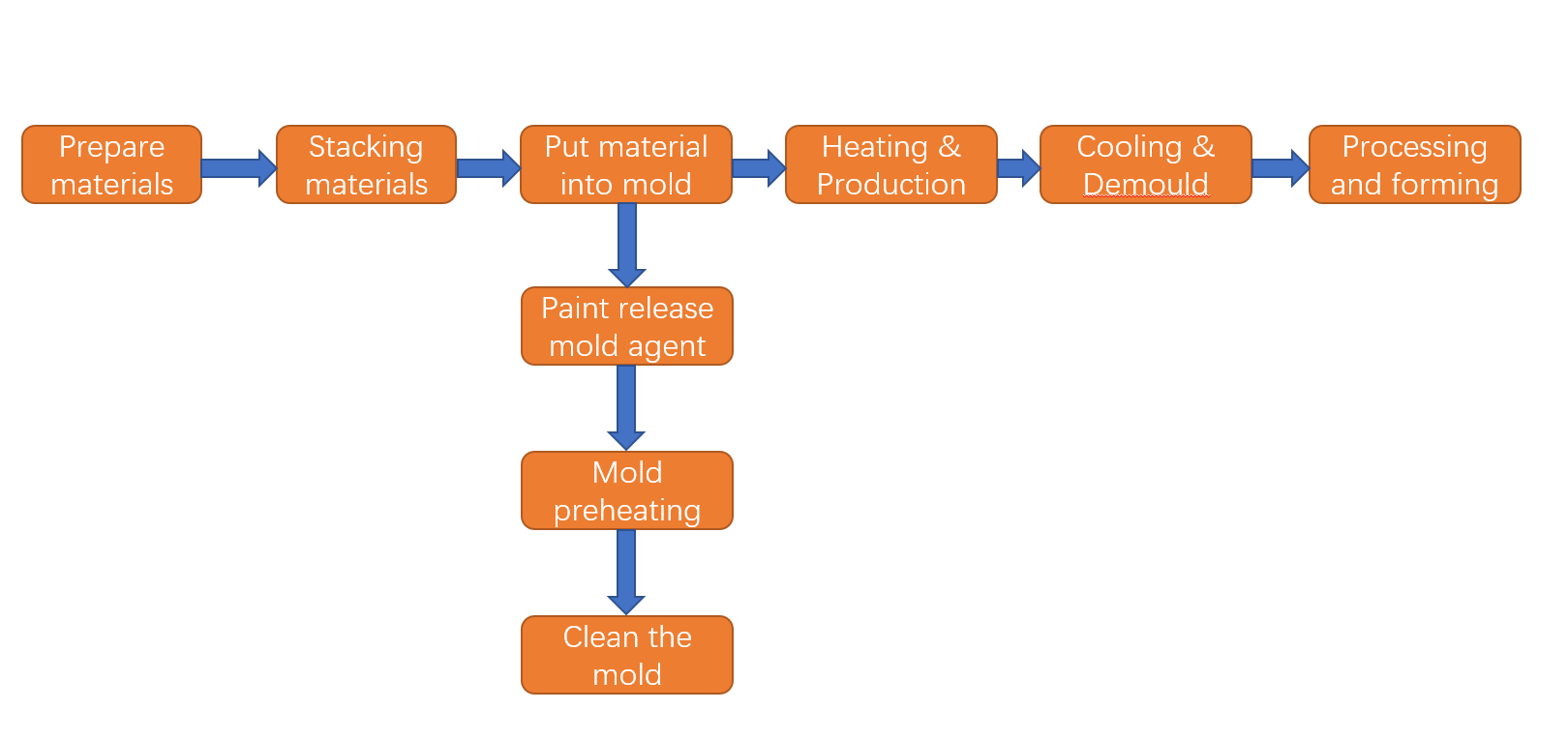

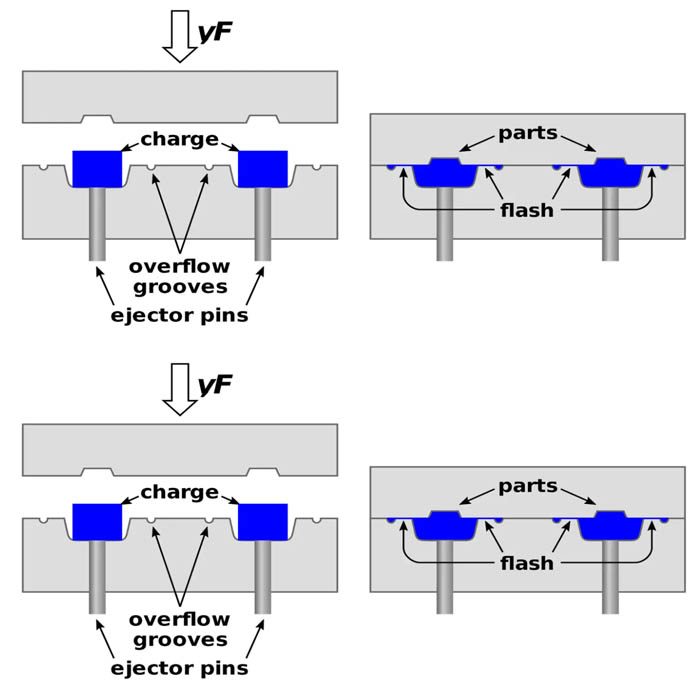

Compression molding process: (1) Feeding: Add a specified amount of material to the mold as needed, and the amount of feed directly affects the density and size of the product. If the amount of feed is large, the product will have thick edges, poor dimensional accuracy, ...Read more -

How to Create Molds for Compression Molding?

Depending on the material or charge you will be compression molding, you have several options for creating molds. The key is that your molds need to be able to withstand the compression molding process, so if you are using heat, you will need to create molds that can ha...Read more -

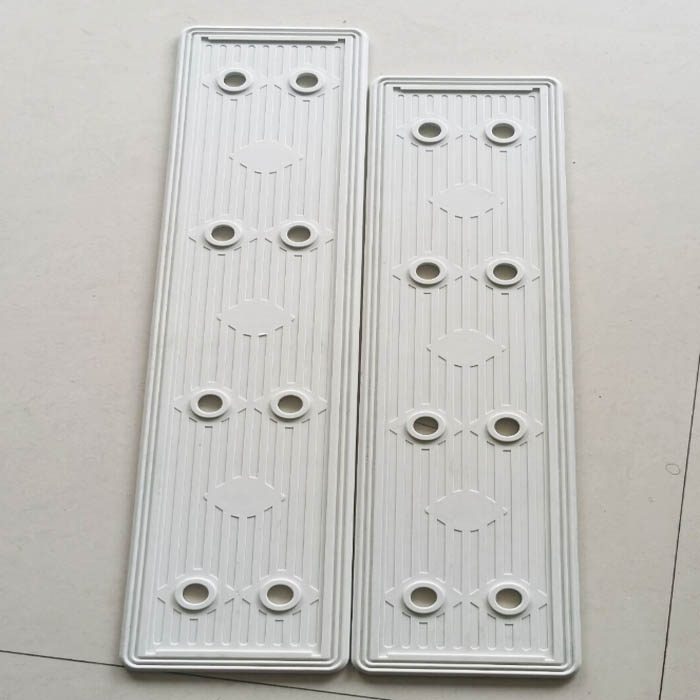

The Applications of Compression Molding

Compression molding has a myriad of applications. Here are some of the many parts and products we interact with that have compression molded parts: Vehicle parts - Many large parts and panels for cars, tractors, and other vehicles are made using compression molding. Man...Read more -

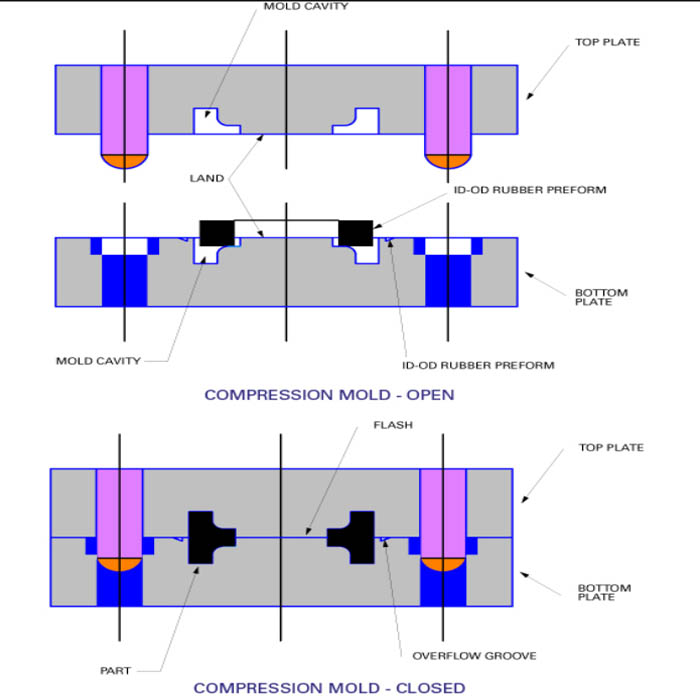

Do you know what is COMPRESSION MOULDING?

Compression moulding normally uses a hydraulic press in which a moulding tool is fixed to top and bottom platens of the press. The moulding tool consists of a top cavity and bottom cavity, designed to produce the part to be manufactured and heated to the required mouldin...Read more -

Advantages and disadvantages of compression molding

Compression molding produces composite parts of varying complexities that are comparable to those manufactured from metal. They offer the same strength and mechanical properties but outperform metals in their weight-to-performance ratio, anti-corrosive and electrically i...Read more -

Composite materials compression moldings maker in taizhou

Composite materials Composites, such as laminated plastics, are also thermosets that are utilized in the compression molding process. Laminated plastics are a special form of polymer-matrix composite that is comprised of layers of fiber reinforced materials that are impr...Read more -

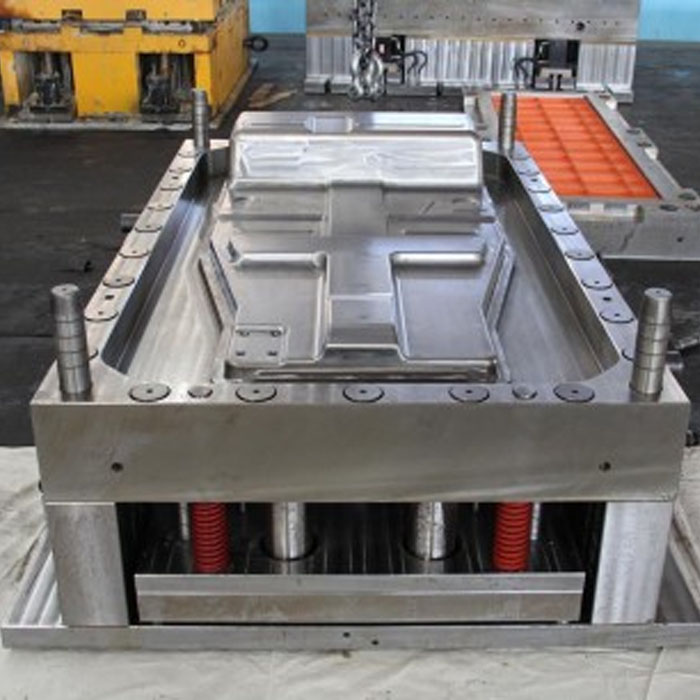

The compression molding process for thermosets

1-The mold, or metal tooling, comprised of a cavity and a core, is installed in the press, and may feature integral heating to control temperatures throughout the process. Temperature can also be controlled from the platens of the hydraulic press. 2-Once the tool is inst...Read more