-

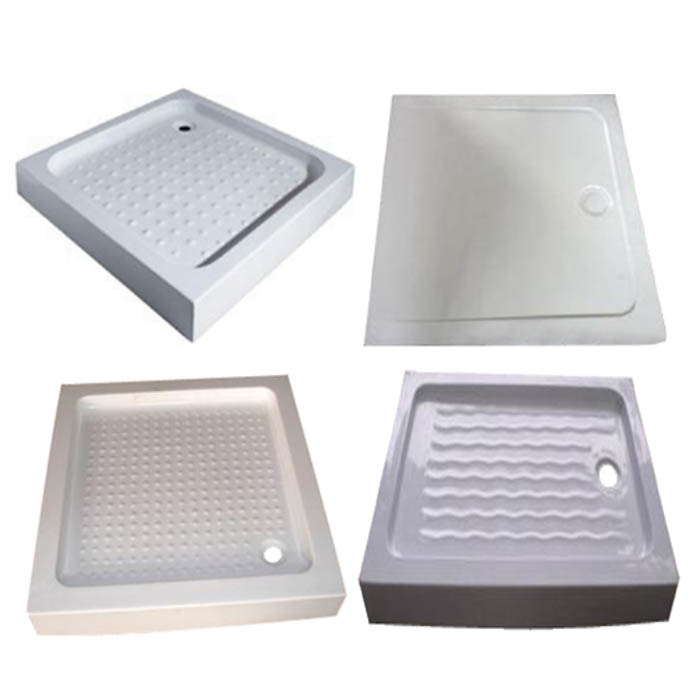

Bathroom compression molds introduction

In the sanitary ware industry, molds are usually called sanitary molds. The integral bathroom is an integral frame composed of an integrated waterproof chassis wall panel and top plate, and is equipped with bathtub, sink, faucet, shower, ceramic tiles and other bathroom ...Read more -

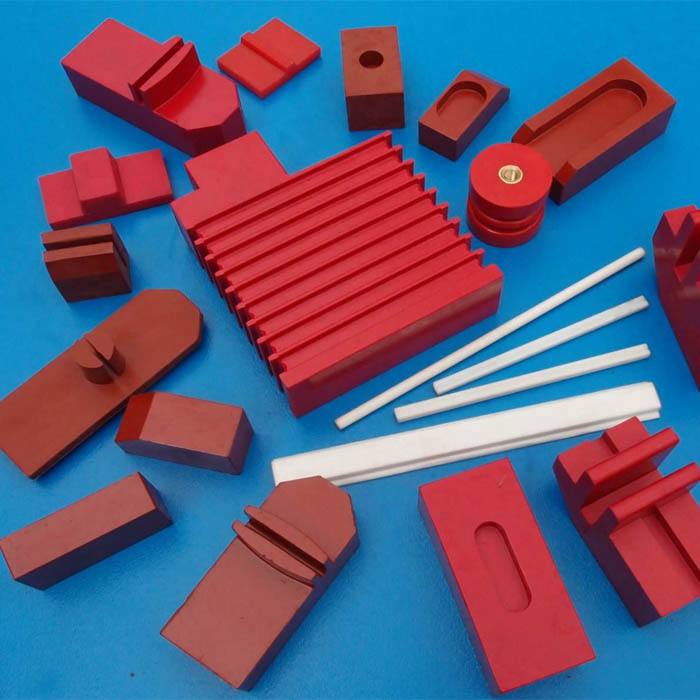

Electronic product compression moulds

In modern society, more and more products use electronic components. Electrical components are used in medical equipment, household appliances, and automotive products. The demand for electrical or electronic equipment continues to grow. DEYING produces plastic compressi...Read more -

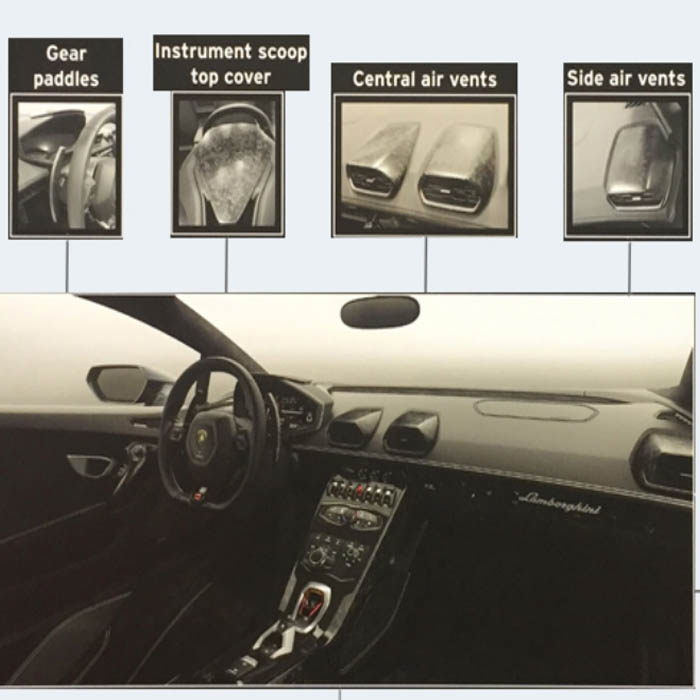

Automotive mold application

With the rapid development of the automotive industry, automotive molds have become the most important part of the mold industry, and the scale of the industry continues to expand. In the future, driven by the concept of lightweight automobiles, the development of automo...Read more -

What is Carbon fiber mold?

Carbon Fiber Mould> Carbon Fiber Mould Carbon fiber, also known as graphite fiber, carbon graphite, referred to as CF (Carbon Fiber). It is a microcrystalline graphite material obtained by piling up flake graphite microcrystals and other organic fibers along the fiber...Read more -

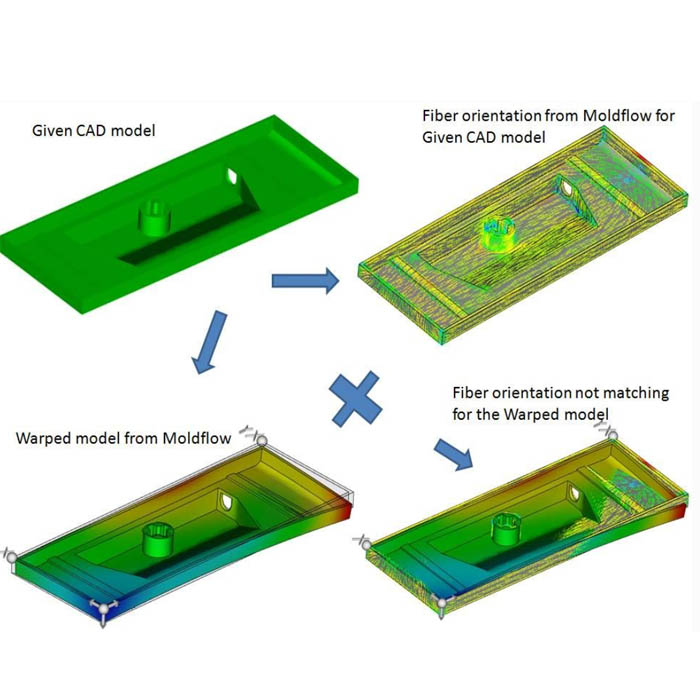

What is LFT compression molds?

LFT Mold> Compression Mold / LFT Mold LFT is: long glass fiber reinforced thermoplastic. Parts made of LFT materials have the characteristics of light weight, high hardness, good elastic modulus, high impact strength, tensile strength, and high temperature resistance,...Read more -

What is GMT compression mould?

GMT Mould> Compression Mould / GMT Mould GMT is a glass mat-reinforced thermoplastic. GMT fiber composite has high flow properties, enabling the production of thin-walled automotive components to achieve low-cost features. The impact resistance, mechanical strength an...Read more -

What is BMC compression molding?

BMC Mould> Compression Mould / BMC Mould BMC is the abbreviation of Bulk Molding Compounds, that is, bulk molding compound. It is often referred to as unsaturated polyester agglomerate molding compound in China. Its main raw material is a dough-like prepreg that is fu...Read more -

What is SMC compression molding?

SMC is sheet molding compound. The main raw materials of SMC are composed of GF (special yarn), UP (unsaturated resin), low shrinkage additives, MD (filler) and various additives. SMC has the advantages of superior corrosion resistance, soft quality, easy engineering des...Read more -

Composite material mold introduction from DEYING

Composite materials are made up of two or more materials with different properties through physical or chemical methods to form materials with new properties. With the broadening of the application field of composite materials, the composite material molding industry has...Read more -

Production process of glass fiber reinforced plastic mould

1. Accept the task book of FRP mold The task book for forming FRP parts is usually proposed by the part designer, and the content is as follows: 1). Formal drawing of the finished product after review and signing, and indicate the brand and technical parameters o...Read more -

What is SMC BMC compression moldings?

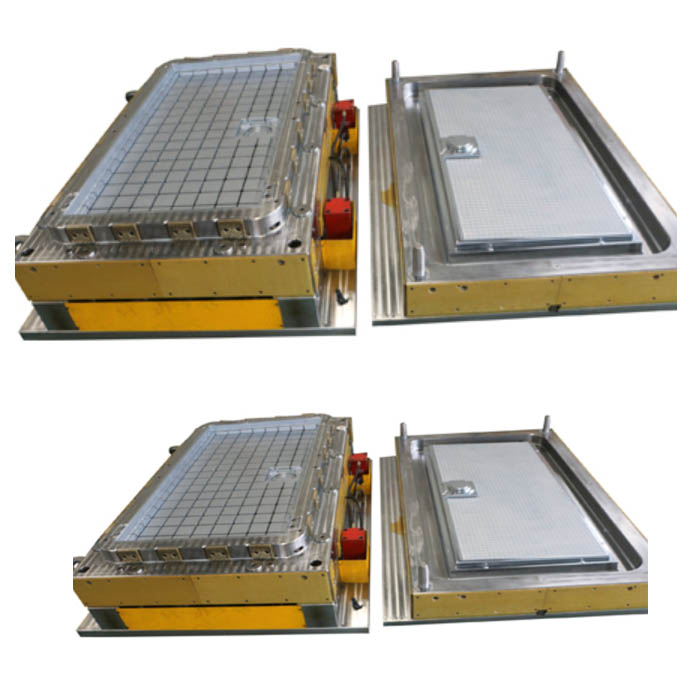

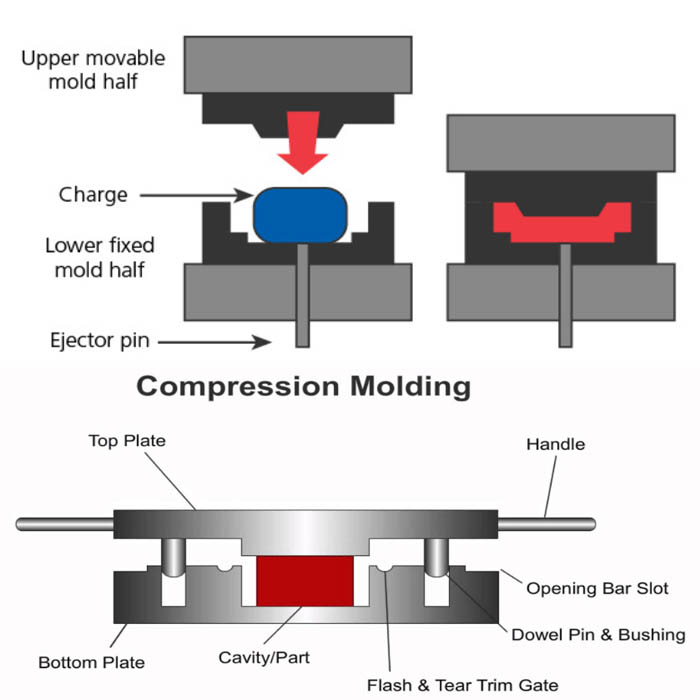

Compression moulding normally uses a hydraulic press in which a moulding tool is fixed to top and bottom platens of the press. The moulding tool consists of a top cavity and bottom cavity, designed to produce the part to be manufactured and heated to the required mouldin...Read more -

Application of SMC and BMC products

Automobile industry Due to the good physical properties of SMC and BMC, they are widely used in the automotive industry. Such as bumpers, seat frames, battery boxes, engine under covers, structural beams, etc. Achitechive In the construction industry, due to the good the...Read more -

What are the characteristics of SMC materials? SMC molded product planning

Our friends often ask the editor about SMC materials, SMC molds and other related questions. The editor cannot answer them one by one. We can only briefly introduce the characteristics of SMC materials and the planning of SMC molded products through this article. , The c...Read more -

SMC FRP compression molds need to pay attention to details

Details determine success or failure, and I believe my friends will all understand this truth. This is especially true in industrial production. This is especially true for the production of SMC FRP molds, otherwise the slightest error will be too far, and the impact wil...Read more -

SMC materials frequently encountered problems in the molding process and their treatment methods

Everyone knows that the SMC molding process has many advantages, such as: accurate product size, smooth surface, good product appearance and size repeatability, complex structure can also be molded once, and secondary processing does not need to damage the product. It ca...Read more -

Talking about the key points of SMC mold design

The manufacturing of many products is a very important part of the early mold design. Imagine if the product mold has a design flaw, then the product is naturally flawed. Today, the editor of DEYING Mould came to talk to my friends briefly about several key points of SMC...Read more -

The difference between SMC BMC compression molds and injection molds

SMC molds basically follow the same rules as injection molds, but SMC and BMC molds also have different characteristics from injection molds. For example, cutting edges are important considerations in the production of SMC and BMC molds. ...Read more -

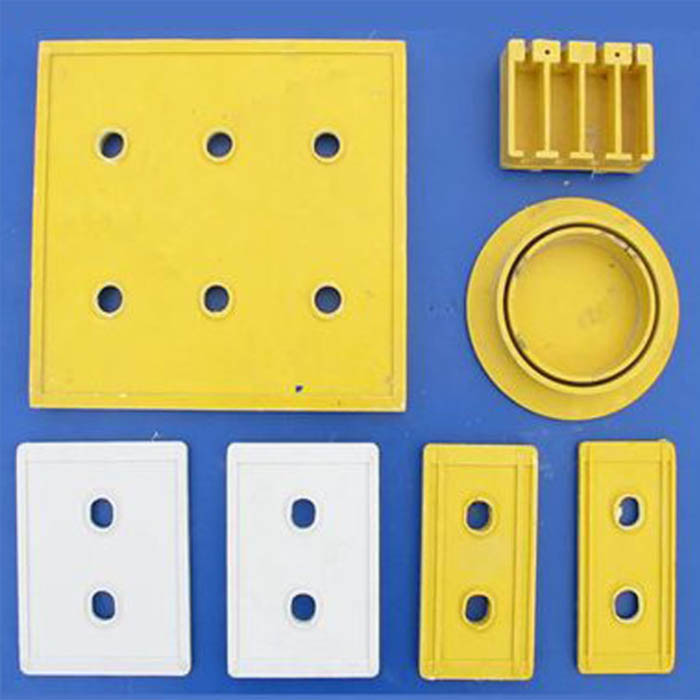

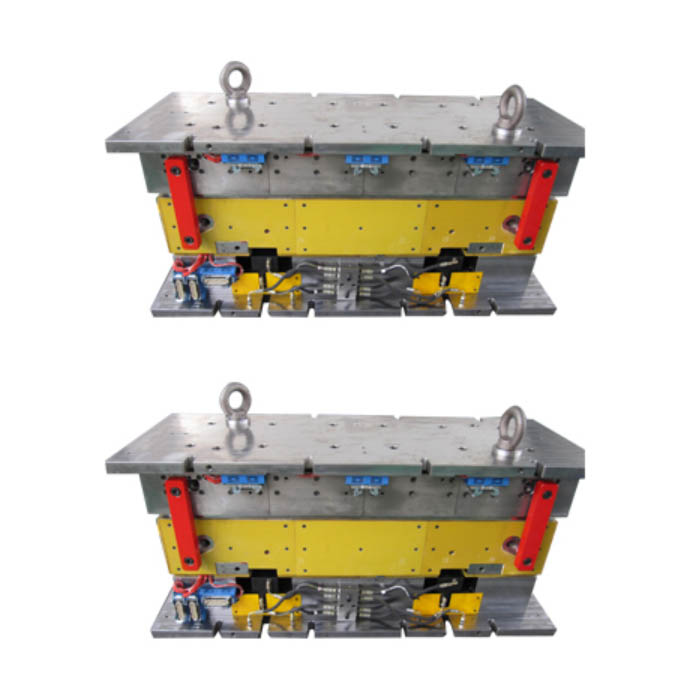

Compression molding mold introduction

Compression molding (also known as compression molding or compression molding) is an operation that first puts powdered, granular or fibrous plastic into a mold cavity at the molding temperature, and then closes the mold to press to shape and solidify it. Compression mol...Read more -

SMC materials frequently encountered problems in the molding process and their treatment methods

Everyone understands that the SMC molding process has many advantages, such as: accurate product size, smooth surface, good product appearance and size repeatability, complex structure can also be molded once, and secondary processing does not need to damage the product....Read more -

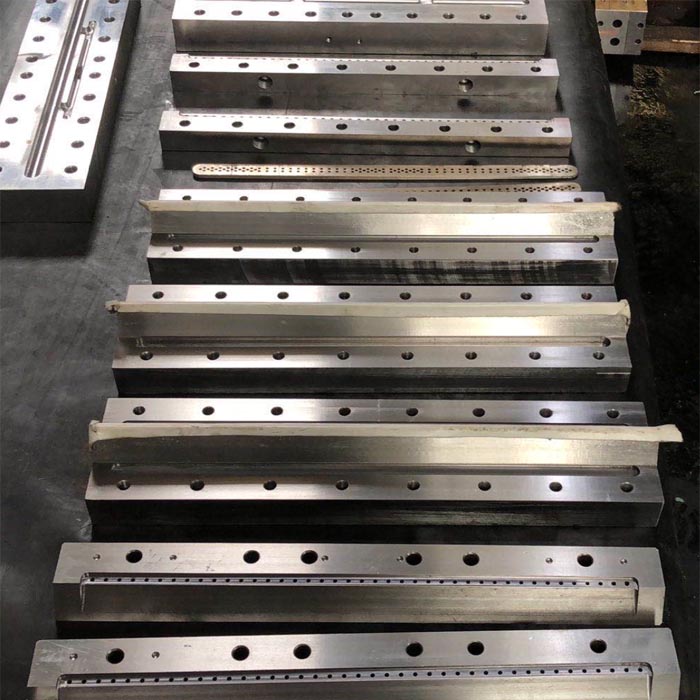

The main types of spinnerets

There are many types of spinnerets, and the spinnerets used to make non-woven fabrics for masks are just one of them. Below, Shengshuo Precision Machinery organizes the main types of spinnerets on the market for you. (1) Spinneret for wet spinning Spinnerets for French s...Read more -

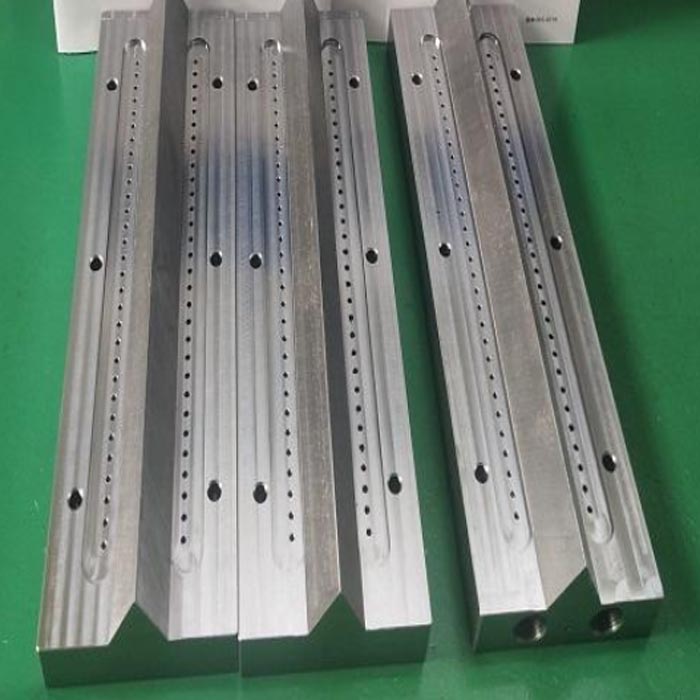

Spinneret micro hole processing to solve 4 major pain points

Spinneret micro-hole processing, using ultra-precision ultrasonic tool holder, to deal with 4 major pain points Can filter bacteria and prevent the spread of viruses Meltblown cloth is called the "heart" of masks! Then why is the spinneret called the "heart" of the "hear...Read more -

Spinneret Cleaning of Melt Blowing Line-Vacuum Cleaning Furnace

The mask non-woven fabric is made of polymer chips with high melt index, which are extruded and heated and melted into a high-temperature melt with good fluidity. The melt will be sprayed from the spinneret using high-temperature, high-speed hot airflow. A production pro...Read more -

How to judge the quality of extrusion die

The use of extrusion molds is also very common. If you do not notice the quality of the selection when using it, it will seriously affect the normal use of the extrusion mold. In order to make the mold use well, the following provides relevant judgments about extrusion T...Read more -

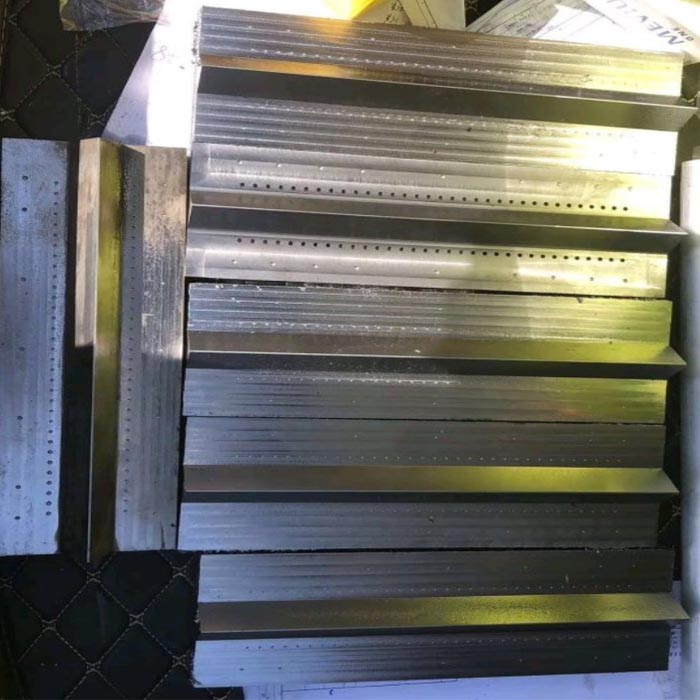

Meltblown moulds spinneret plate molds Non-woven fabric die for extrusion machine

Melt blown cloth, commonly known as the "heart" of masks, and melt blown die head is the core hardware of the melt blown cloth production line. In order to meet market demand, Rongyi has launched a new type of meltblown die head suitable for standard fabric widths from 6...Read more