-

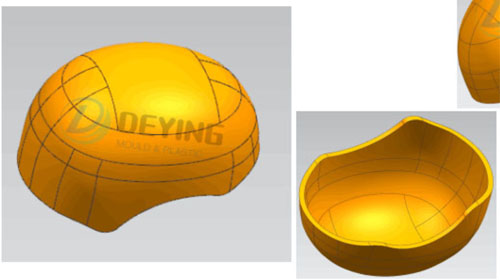

Principle of Helmet Forming Mould

Composite helmets are the most complicated type of helmets. They use various non-metallic materials such as glass fiber, aramid, carbon fiber, etc., to be synthesized with thermoplastic resin. Composite helmets occupies a very important position in bulletproof helmets fo...Read more -

Molding process of Kevlar helmet moldings

Composite helmets are the most complicated type of helmets. They use various non-metallic materials such as glass fiber, aramid, carbon fiber, etc., to be synthesized with thermoplastic resin. Composite helmets occupies a very important position in bulletproof helmets fo...Read more -

What is the difference between an injection mold and a compression mold?

One. Different in nature 1). Injection mold: a tool for producing plastic products, but also a tool for making plastic products complete in structure and precise in size. 2). Compression mold: plastic material is directly added to the open mold cavity, the mold is closed...Read more -

Which is better of plastic helmet or fiberglass helmet?

Compression molding (also known as compression molding or compression molding) is an operation that first puts powdered, granular or fibrous plastic into a mold cavity at the molding temperature, and then closes the mold to press to shape and solidify it. Compression mol...Read more -

Compression fiberglass helmet moldings

The quality of FRP helmets is very good. fiberglass helmets have high strength, good flexibility and strong impact resistance. It is a better helmet in the market today, and has advantages in all aspects than plastic helmets. Professional glass fiber reinforced plastic h...Read more -

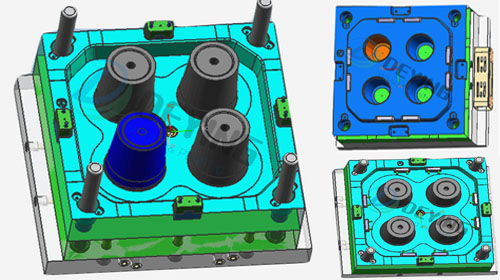

SMC Mould Briefly describe the layup steps of SMC fiberglass molds

The SMC mold is a combined plastic mold for compression molding, extrusion, injection, blow molding and low foam molding. It mainly includes a concave mold combined substrate, a concave mold component and a concave mold combined card board. The concave mold of the variable cavity is a convex mold...Read more -

SMC Septic Tank Mold Explains the development stages and precautions of FRP septic tanks

The four stages and seven precautions for the development of FRP septic tanks are described. Due to the particularity of raw materials, light weight, high strength, no corrosion, no leakage, good water treatment effect, and convenient construction and installation, only digging and burying can ma...Read more -

Compression mold SMC FRP compression molding stage?

1. Mold preheating: Before pressing, open the mold temperature controller to preheat the mold to remove moisture and other volatiles, which can increase the curing speed, shorten the pressing cycle, improve the uniformity of the cured product, improve the physical and mechanical properties of the...Read more -

SMC mold application field

Characteristics and application fields of SMC composite materials The unique performance of SMC composite material solves the shortcomings of wooden, steel, and plastic meter boxes that are easy to age, easy to corrode, poor insulation, poor cold resistance, poor flame r...Read more -

Manufacturing Kevlar bulletproof helmet mold

Manufacturing Kevlar bulletproof helmet mold UHMWPE is commonly known as ultra-high molecular weight polyethylene. Its molecular weight can reach 1 to 5 million. It has high wear resistance, low friction coefficient, highest impact resistance, and excellent sound-absorbi...Read more -

Compression Molding process

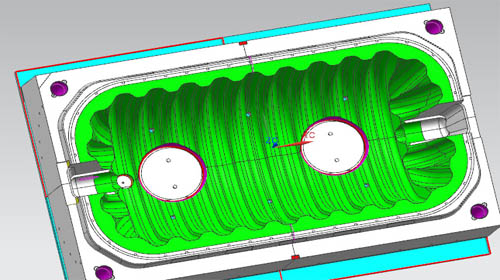

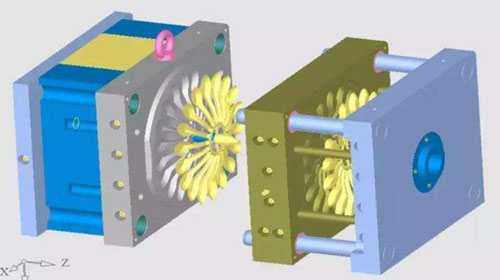

1. Molding method Carbon fiber is a fiber material, so the carbon fiber material molding process uses fiber material molding law. The fiber material molding method is a method of putting pre-mixed or pre-impregnated fiber-shaped molding material into a metal mold to form a composite material pr...Read more -

What are the eight categories of injection moulds?

(1) Single-part line injection molds When the mold is opened, the movable mold and the fixed mold are separated, so that the plastic part is taken out, which is called a single parting surface mold and also called a double-plate mold. It is the simplest and most basic form of injection mold. It c...Read more -

What is the difference between injection mold and compression mold ?

1.Injection Mold Injection molds are parts that give plastics shape and size during molding. Although the structure of the mold may vary widely depending on the variety and performance of plastics, the shape and structure of plastic products, and the type of injection machine, the basic structure...Read more -

Mould base development direction

The future development direction of mold base manufacturing In the manufacturing process, especially in the process of industrial production of mechanical parts, various functional parts must be formed by the formwork. Nowadays, more and more production companies use plastic mold bases to produce...Read more -

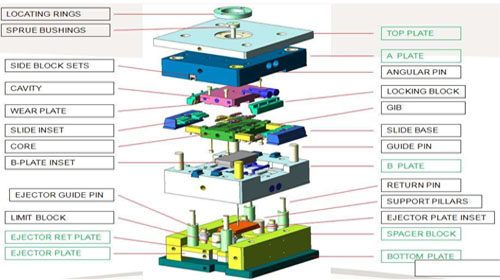

What is mold base?

What is mold base? A complete set of molds for the production of specific powder products by pressing or recompressing. In addition, the support of the mold is also called the mold base. For example, the die-casting machine combines and fixes the various parts of the mold according to a certain r...Read more -

Standard and non-standard mold base

The difference between standard mold base and non-standard mould base Standard mold base processing equipment is mainly milling machines, grinding machines and drilling machines. The milling machine and the grinding machine process 6 faces to the specified size. The drilling machine will not req...Read more -

What is role of mold base in the mold?

Many of the mold base are standard parts. For stamping dies: the mould base consists of upper mold/core and lower mould/cavity, mold shanks and guides. The mould base is the skeleton of the entire pair of molds, and all the parts of the mold are fixed on it and subjected to the full load of the s...Read more -

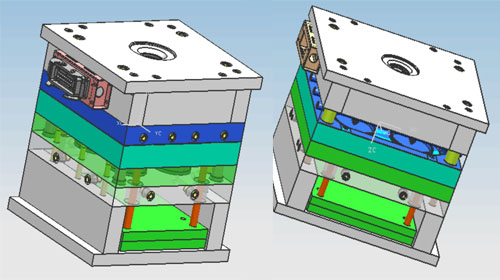

Detailed analysis of the mold structure

The injection mold consists of two parts: a movable mold and a fixed mold. The movable mold is mounted on the moving template of the injection molding machine, and the fixed mold is mounted on the fixed template of the injection molding machine. In the injection molding, the movable mold and the ...Read more -

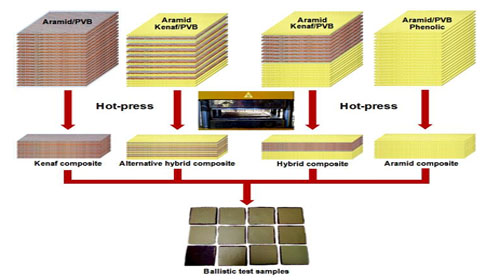

How to production aramid helmet?

Aramid Helmet production steps as belows:Read more -

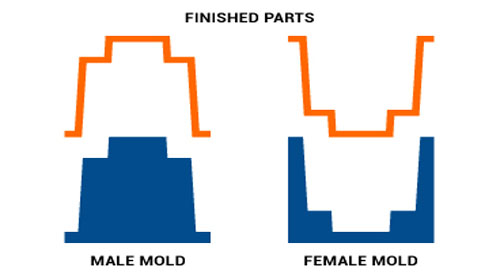

What is Male and female molds?

Male and female molds are the two main types of forms, but they produce significantly different finished parts. The most time consuming and cheapest method is a male (or positive) mold. This is a form that mimics the final shape of a part by being fabricated on its outer surface. Indeed, this typ...Read more -

Deying Mold Making Process Flow

Deying Mold Making Process Flow 1. Sawing machine cutting 2. Milling machine processing 3. External vacuum heat treatment 4. Grinding machine processing 5. CNC machining (programming) 6. W/C (wire cutting) 7. EDM (spark machine) 8. Polishing 9. The fitter assembles OK, tryout Checkpoints after mo...Read more -

Tips for testing molds for injection molds

Tips for testing molds for injection molds as belows: First, the precautions before the test 1. Understand the relevant information of the mold:It is best to get the design drawings of the mold, analyze it in detail, and get the mold technician to participate in the test work. 2. Chec...Read more -

BMC DMC material of compression mould

BMC is the initial abbreviation of English Bulk Molding Compound, and the Chinese name is a group molding compound. BMC is a semi-dry method for manufacturing glass fiber reinforced thermosetting products. It is pre-mixed into a paste by unsaturated polyester resin, low shrinkage/low profile addi...Read more -

Sheet SMC material of compression mold

SMC composite is the abbreviation of Sheet molding compound, namely sheet molding compound. The main raw materials are composed of SMC special yarn, unsaturated resin, low shrinkage additive, filler and various additives. SMC has superior electrical performance, corrosion resistance, light weight...Read more