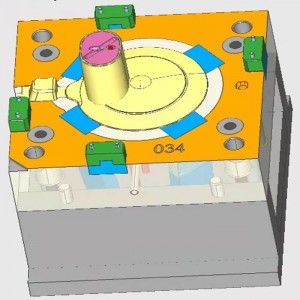

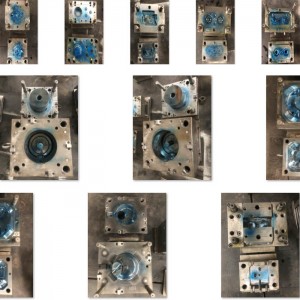

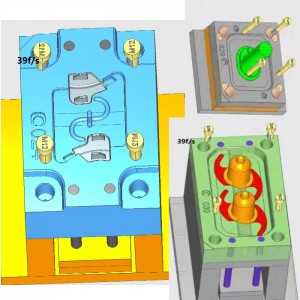

In the domestic and foreign markets, the juicer industry is in a period of rapid growth. DEYING MOLD specializes in the production of juicer cup transparent cup juice cup molds. The design of the juicer shell mold is complex, and the side has an inverted button, which is used in mold design. It is the structural design of the large side row, and the oblique guide column is also very long here.

How can I make a mold for an injection molding juicer? First, select the right steel material for the mold base and the mold core cavity. In addition, you must use high-hardness steel as the mold base, and then select the appropriate mold standard parts. A good plastic material filling system requires special hot runner system assistance. Forming, and to ensure that the cooling system achieves the best results. For injection molds, Taizhou DEYING MOLD is a plastic mold manufacturer that specializes in manufacturing and processing injection molds. It also provides plastic product processing services, high-speed milling external processing services, and we pay great attention to the quality of molds.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

High quality plastic injection fish crate box m...

-

plastic injection Baby bath mold child bathtub ...

-

Food lunch box mould disposable thin wall box p...

-

plastic mop bucket injection mould mop barrel p...

-

Rectangular fast food Serving tray mould plasti...

-

China taizhou plastic injection baby bathtub mo...