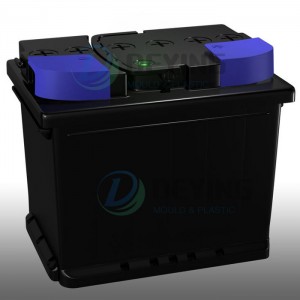

Lead acid automotive Car auto battery box mould beryllium copper guaranteed fast cycle times and cooling. Annual production capacity of 50-80 sets of battery container and case molds plastic molding to export all around the world.

In general,the material of product is PP and mould steel will use P20,718,H13 and so on.battery box mold is hot runner and stripper plate to ejection,high-speed production of fully automatic demoulding praised by customers.

How to control each of lattice size is same ?

1.This is crucial for mold production,It can’t be too loose or too tight. If it is too loose, the battery case will expand when charging; if it is too tight, the battery case will not be charged.

2.Therefore, after more than 20 years of experience, our company has found the best solution for controlling the size. Our engineers will first perform a mold flow to analyze the deformation of the battery case.

3.According to this report, our designers will choose the appropriate injection point position to maintain the injection balance. In addition, our mold waterway design is very dense, in order to achieve good cooling.