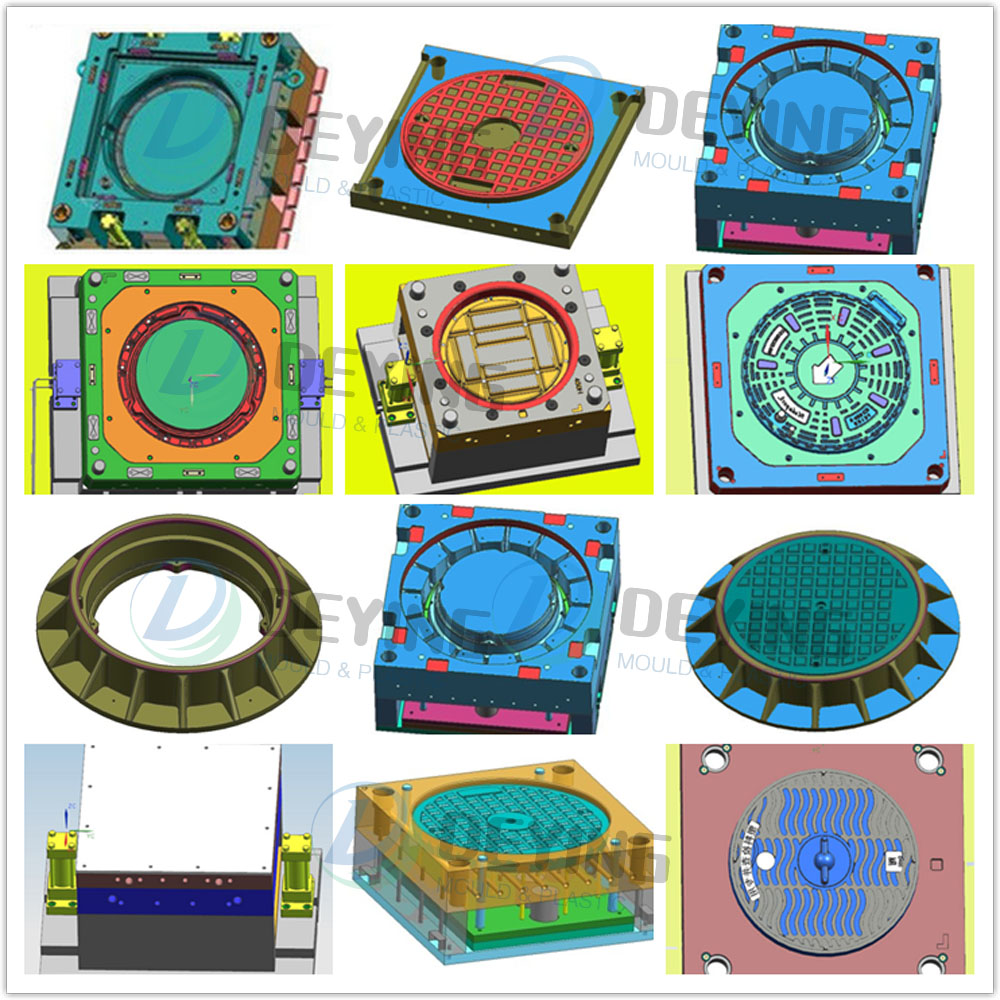

DEYING MOLD focus on the development and manufacturing of composite molds such as SMC, BMC, GMT, etc. The company uses advanced software such as CAE\CAD\CAM\CAQ to assist mold development and quality control; has advanced CNC machining equipment to ensure the high precision and high quality of the mold; continuously optimizes the process flow and powerful CNC machining capabilities , Scientific project management, greatly shorten the production cycle of molds, and provide a powerful guarantee for the rapid listing of your products.

Composite materials are made up of two or more materials with different properties through physical or chemical methods to form materials with new properties. With the broadening of the application field of composite materials, the composite material molding industry has developed rapidly, the old molding process is becoming more and more perfect, and new molding methods are constantly emerging. Commonly used processes include hand lay-up, injection molding, resin injection (RTM), compression molding (BMC, SMC), and vacuum diversion molding processes.

The composite molds we produce have been effectively optimized, have a longer service life, lower manufacturing costs, and their products can achieve higher precision.

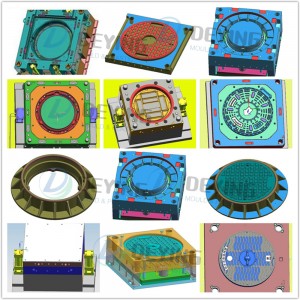

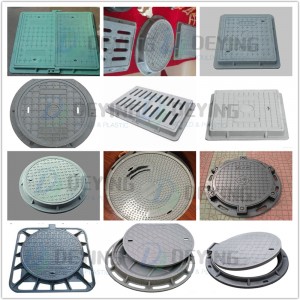

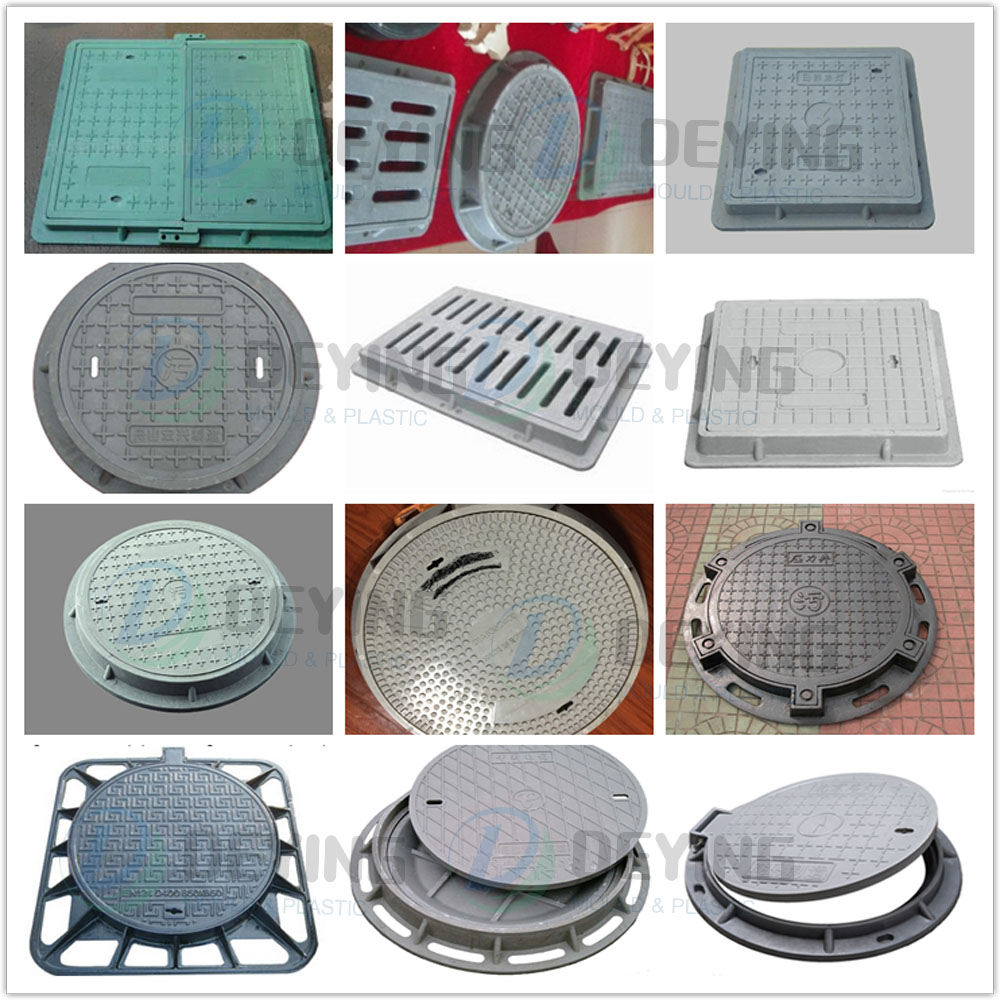

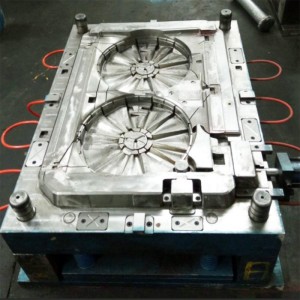

Processing and supply of plastic SMC cover mold

[Mold types] Electric meter boxes, daily necessities, auto and motorcycle parts, plastic pipe fittings, home appliances, chairs, cups, trash cans and other plastic product molds.

[Mold Base] LKM, HASCO, DME and other standard mold bases.

[Mold material] 45#, 60#, P20, 718, 7138, NAK80, S136, SKD61, etc.

[Gating] Hot runner and cold runner.

[Design software] Moldflow, UG, PROE, AUTOCAD, Cimatron E, etc.

[Plastic materials] PP, PVC, PC, PMMA, ABS, AS, PE, PS, PA6, etc.

[Mold life] not less than 1 million times.

[Quality System] ISO9001: Quality System.

[Production cycle] 15-50 days.

[Place of Origin] Huangyan, Taizhou, Zhejiang.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

BMC SMC Plastic Injection Molding Products Manh...

-

Composite Cable Trench Cover Plate mould FRP Ma...

-

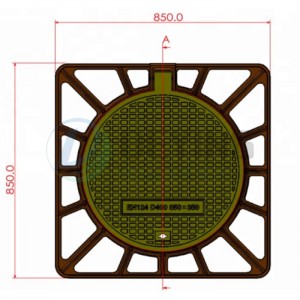

New Design Manhole Cover Moulds Plastic with Hi...

-

FRP Composite Manhole Cover molds Custom Made

-

compression Mould Company Sewerage Manhole Cove...

-

SMC Sheet Used for Molded Manhole Covers moldin...