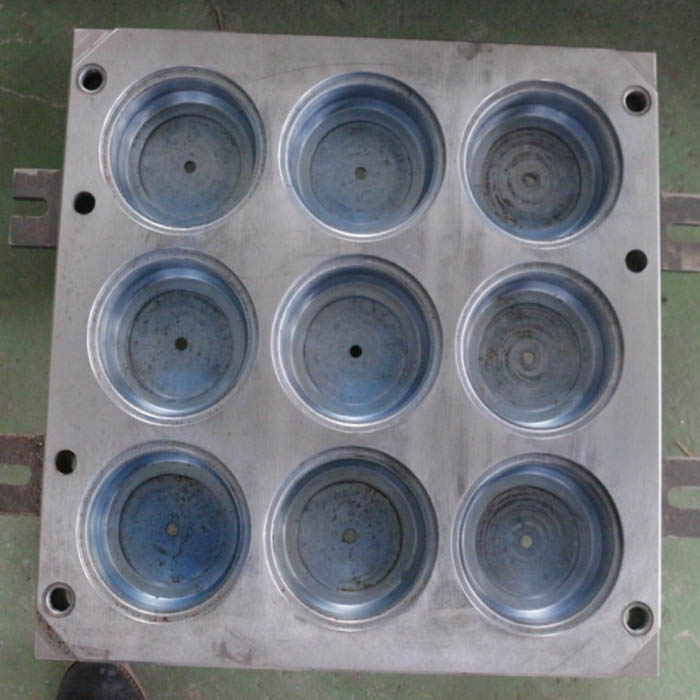

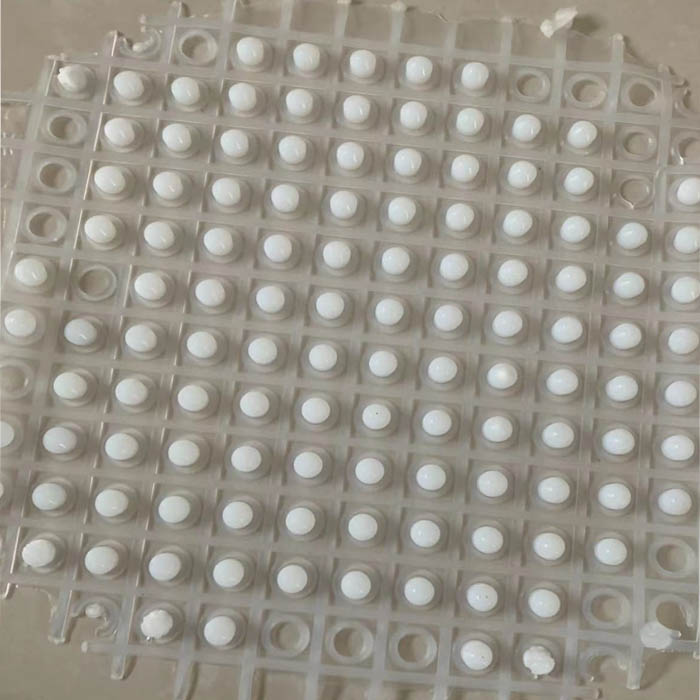

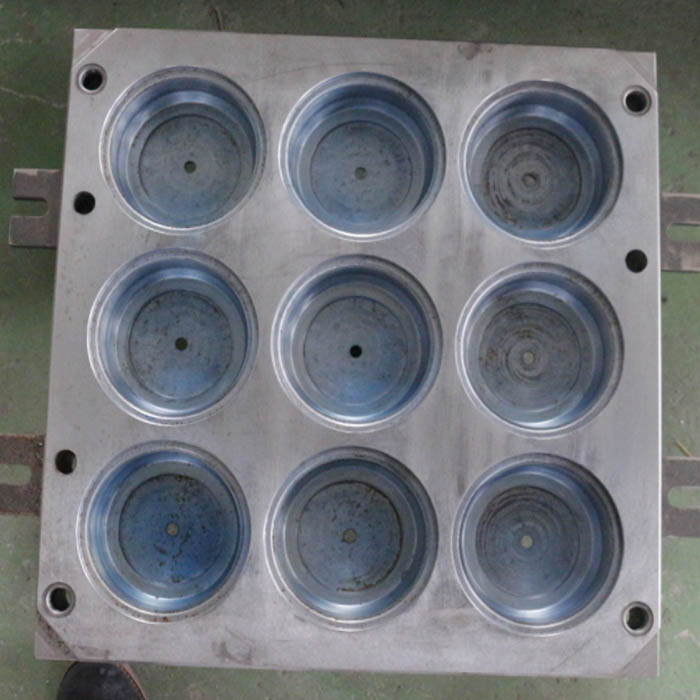

the production and processing of molded rubber products Rubber Flange Gasket molds, moulds are important tools to control and ensure product geometry, assembly dimensions and meet product tolerance requirements. The quality of the mold directly determines the dimensional accuracy and appearance quality of the rubber product. As we all know, rubber products are mixed with raw rubber and many different properties of compounding agents. Under high temperature and high pressure, the compound is fed into the mold cavity of a certain shape and allowed to flow, so that the compounded compound is filled with the design. The cross-linking reaction in the groove of the cavity makes it a valuable vulcanizate product.

The product made from rubber as raw material and vulcanized under high temperature and high pressure with a mold is called a rubber model product. The larger one has automobile tires, and the smallest one has a lighter sealing ring with a diameter of only 50 millimeters. The mold material, dimensional accuracy, exhaust and mold opening difficulty, etc. all directly affect the quality, labor intensity, and production efficiency of rubber products. At the same time, the selection of mold material, heat treatment and other manufacturing processes, as well as the quality of mold assembly, directly affect the service life of the mold. Therefore, when designing the mold, firstly, we should carefully analyze and study the characteristics of the shape and structure of the rubber parts, and use this as a basis to select and design a reasonable mold structure, reasonable material and heat treatment process to meet the requirements of rubber products and the use of molds. It is required that the mold is easy to open after vulcanization, which can provide the production efficiency and the service life of the mold, thereby improving the economic benefit.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

White water bucket mold manufacturer plastic bu...

-

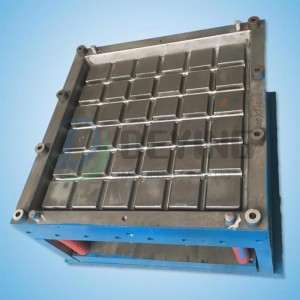

Mold Factory sell SMC BMC FRP Manhole Cover moulds

-

SMC Watertight Manhole Cover mold Composite com...

-

Size 300*50 Cm Plastic Manhole Cover Mould for ...

-

Unidirection Prepreg Carbon Fiber bulletproof h...

-

restaurant hotel 12/16/20/24 bottles beer bottl...