Currently, most manhole covers use SMC or BMC materials instead of steel parts. The ideal performance of SMC material can reach 400-900KN, which can ensure the passage of heavy trucks. In addition, the SMC manhole cover has the advantages of high strength, high precision and corrosion resistance, and its weight is reduced by 1/3 compared with steel parts.

The compression molding process can produce high-strength and complex manhole covers of various sizes. The filling of the manhole cover can be manually or automatically placed in the manhole cover mold; the heated half mold is closed, and the pressure from 500T to 4000T can be applied in the DEYING workshop. The cycle time ranges from one minute to five minutes, depending on the specifics. It depends on the size and thickness of the part. Features such as ribs, bosses and inserts can be molded.

DEYING molds have cooperated with international manufacturers in many fields such as aerospace, automobiles, trucks, high-speed rail, medical, etc., and have been approved by them and issued authorization licenses. Provide customers with solutions in the application of composite materials, and provide customers with feasibility analysis and technical support in the development of new products. While developing for the high requirements of the surface of SMC products, MDC uses a vacuum exhaust system on the mold; while developing for SMC automotive parts, it uses in-mold spraying technology according to customer requirements to integrate the products in the production process.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com

-

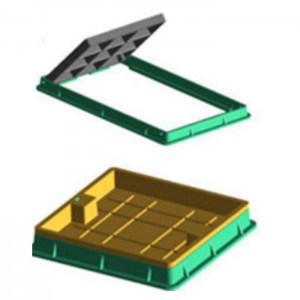

Injection Mould Manhole cover with Three Ways Mold

-

Heavy Duty 600X600 Sewer Manhole Cover Frame mo...

-

Size 300*50 Cm Plastic Manhole Cover Mould for ...

-

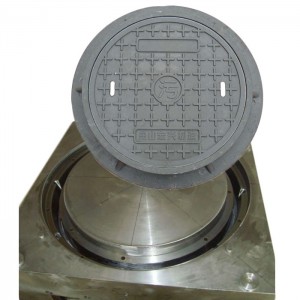

Heavy Duty Circular Round Manhole Cover molding...

-

Customized FRP SMC Steel Mold for Manhole Cover...

-

Round Telecom Composite Manhole Cover mould Pro...