Many domestic manhole cover mold companies feel the livelihood crisis, and the manhole cover mold market competition has gradually entered incandescence. Many companies have realized the importance of self-innovation, and plastic mold companies have made progress in understanding, self-innovation and invested in high-tech talents. Improve from time to time. Domestic manhole cover molds have been steadily developed, and higher demand for manhole cover mold production has been put forward. The following are the requirements:

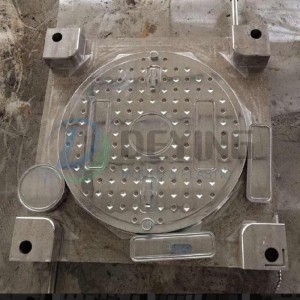

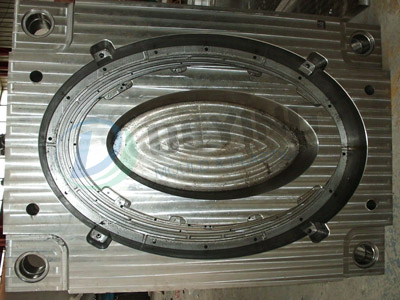

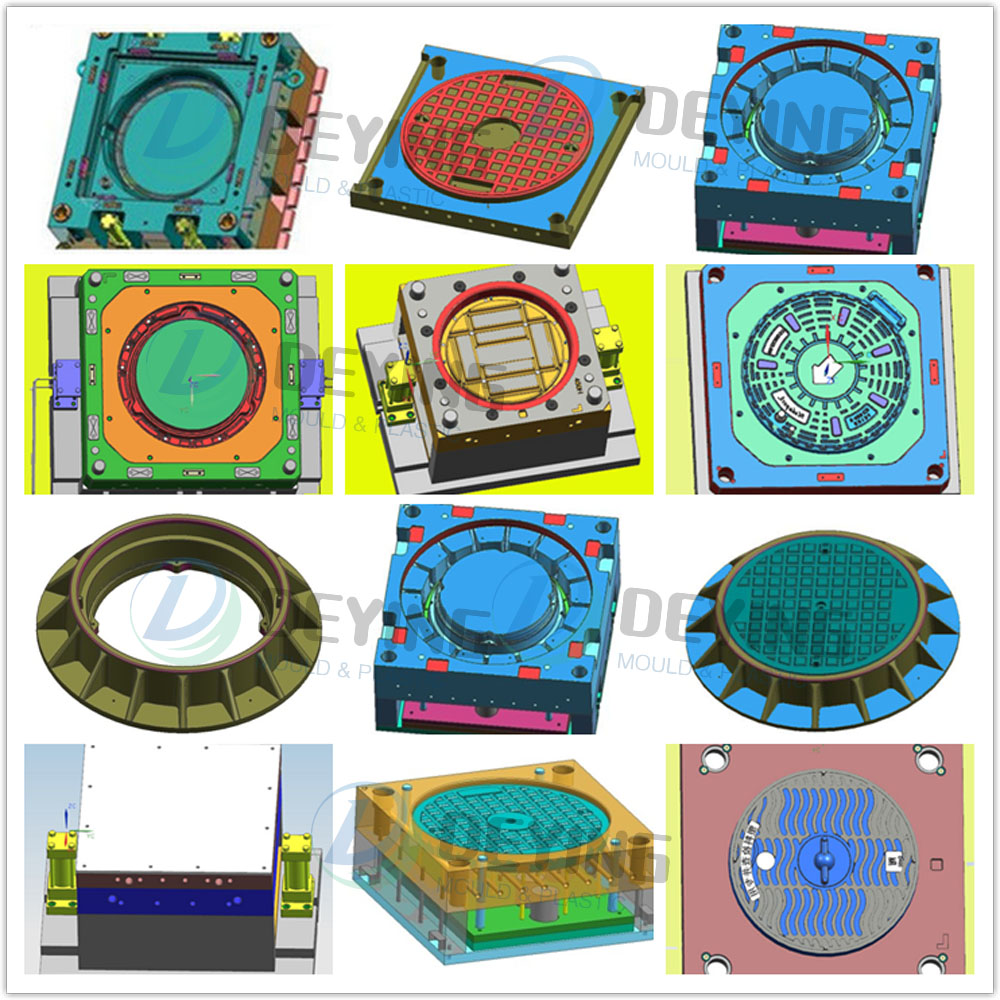

The high-precision machining of the three-dimensional surface of the mold puts forward the requirements of high dynamic precision functions. High-speed and high-precision must be completed with the cooperation of the machine's high rigidity, thermal stability, high reliability and high-quality control system. For messy cavities and multi-functional composite molds, as the shape of the part becomes messy, it is necessary to improve the level of drawing and production of the mold. Multiple grooves and multiple raw materials are formed in a set of molds or assembled into a multi-functional composite mold. , It requires a large amount of machining programming sequence, deep cavity induction cutting ability and high stability, which improves the difficulty of machining.

Manhole cover moulds are in the same field of competition with international competitors. my country's manhole cover mold industry gives full play to its own advantages and strives to occupy a place in the international market. Our country's low labor cost and raw material prices, which make our country the focus of attention in the current international environment where cost saving is urgently needed.

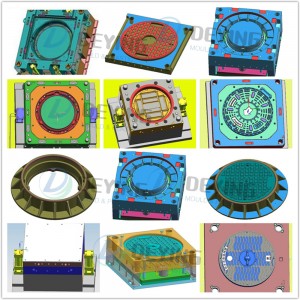

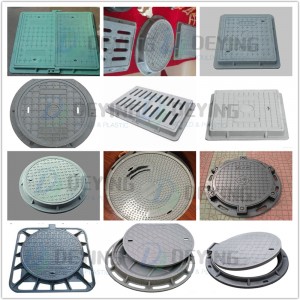

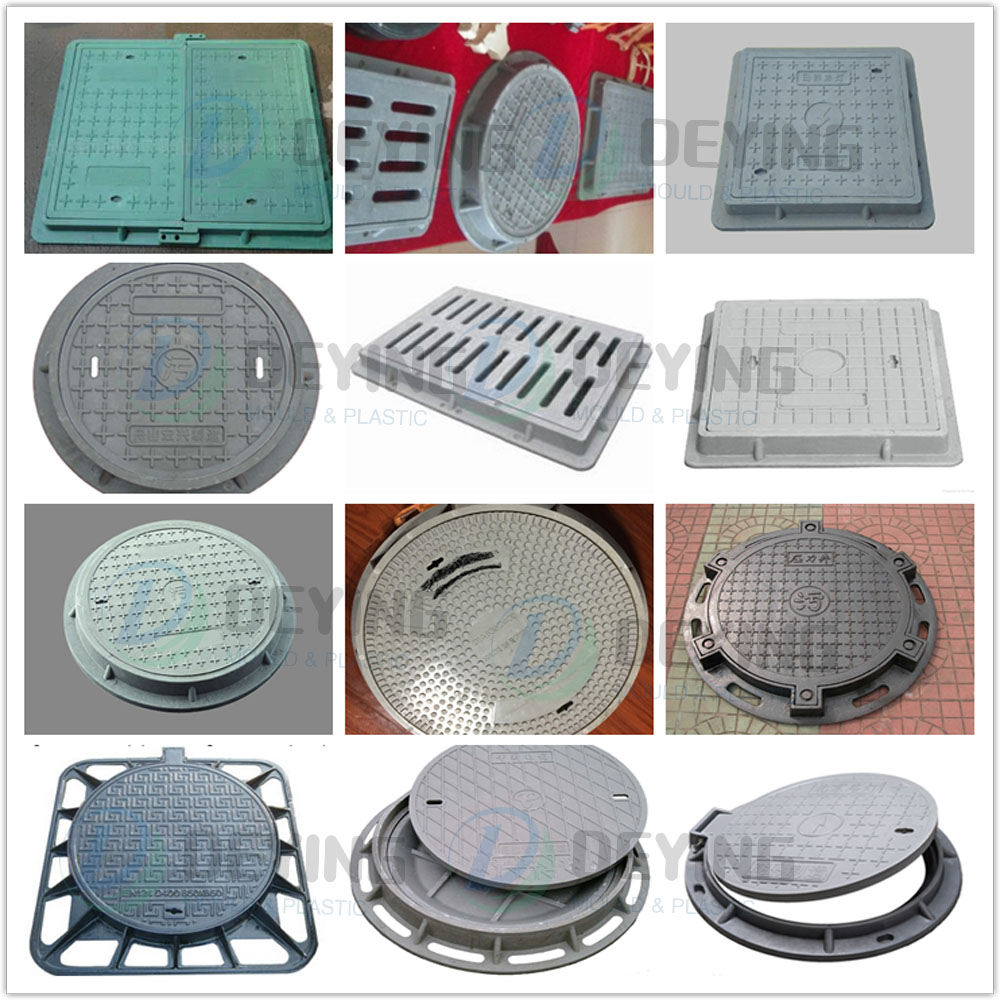

The types of manhole cover molds are: cement round manhole cover mold, county municipal manhole cover mold, inspection manhole cover mold, cement water manhole cover mold

Vehicles traveling on the road have alternating loads on the manhole cover, and the bearing capacity is one of the most important properties of the manhole cover mold. The fatigue damage of the manhole cover should be the most serious, so the evaluation of the bearing capacity of the manhole cover is in addition to the static load test , Should carry out dynamic load test and fatigue test. Fatigue test helps to evaluate the service life of the manhole cover, and the determination of the service life provides a basis for ensuring the safe use of the manhole cover. Manhole covers are mostly used in cities and towns, factories and mines, and large-scale material distribution centers. The use conditions are different, and the corresponding use level should be determined.

The corresponding manhole cover products are prepared according to different use conditions, which can not only meet the use requirements of various roads and sites, ensure the safety and reliability of the manhole cover during use, but also make the most reasonable use of information to prevent waste of resources and reduce The production and use cost of the manhole cover. The existing industry recommendations of the Ministry of Construction divide the load-bearing grade of cast iron manhole covers into heavy and light.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com