SMC is sheet molding compound.

The main raw materials of SMC are composed of GF (special yarn), UP (unsaturated resin), low shrinkage additives, MD (filler) and various additives.

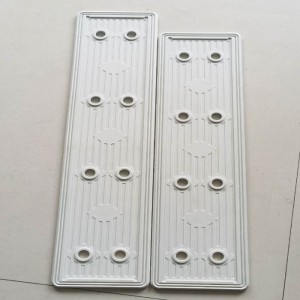

SMC has the advantages of superior corrosion resistance, soft quality, easy engineering design, flexibility, etc. Its mechanical properties are comparable to some metal materials, and the products it manufactures have the advantages of good rigidity, deformation resistance, and wide operating temperature range.

At the same time, the size of SMC products is not easy to deform and has excellent heat resistance; it can maintain its performance well in cold and hot environments, and is suitable for outdoor anti-ultraviolet and waterproof functions.

Application fields of SMC products

SMC composite materials and SMC molded products have excellent electrical insulation properties, mechanical properties, thermal stability, and chemical resistance. Therefore, the application range of SMC products is quite wide, mainly in the following application areas:

1. Applications in the electrical industry.

2. Application in the automobile industry.

3. Application in railway vehicles.

4. Application in communication engineering.

5. The application of explosion-proof electrical equipment enclosures, etc.

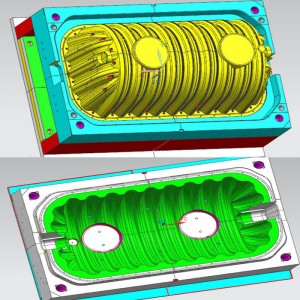

As a supplier of SMC molds, DEYING mold has many years of research in SMC mold design and SMC mold technology, and has a matching test line for SMC molds to ensure that SMC molds meet customer needs from initial design to subsequent mass production.

DEYING molds have cooperated with international manufacturers in many fields such as aerospace, automobiles, trucks, high-speed rail, medical, etc., and have been approved by them and issued authorization licenses. Provide customers with solutions in the application of composite materials, and provide customers with feasibility analysis and technical support in the development of new products. While developing for the high requirements of the surface of SMC products, MDC uses a vacuum exhaust system on the mold; while developing for SMC automotive parts, it uses in-mold spraying technology according to customer requirements to integrate the products in the production process.

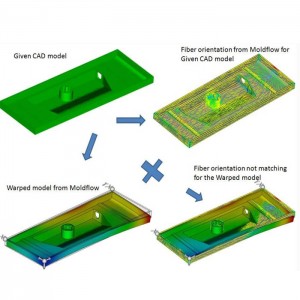

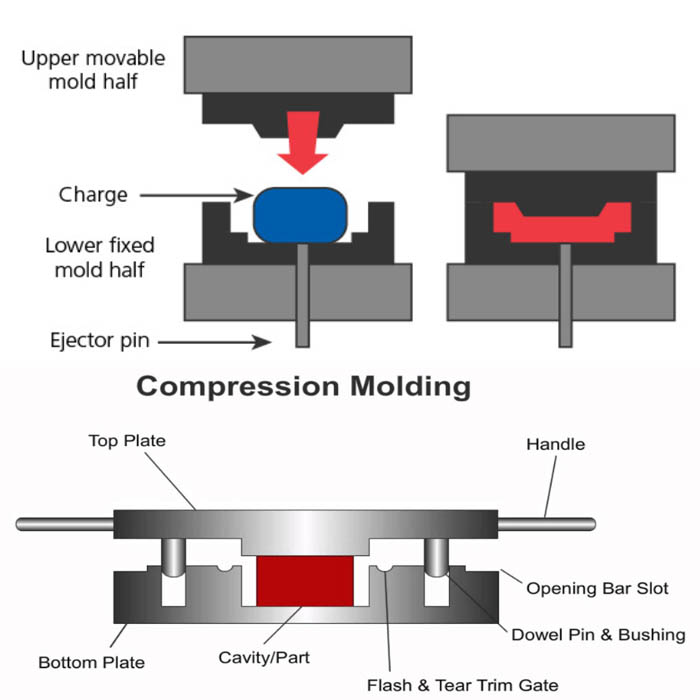

SMC is a combination of long chopped glass strands, mineral fillers and liquid thermosetting resin in the form of a malleable sheet material. Processing of SMC of is typically done by compression or injection molding.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com