The core component of melt blown cloth equipment—spinneret

The spinneret for melt spinning is a representative spinneret for the manufacture of synthetic fibers such as polyester and nylon. The thermoplastic resin is heated and melted,and it is extruded through the spinneret in air or water at a certain speed and cooled.

Spinning method that solidifies into fibers.

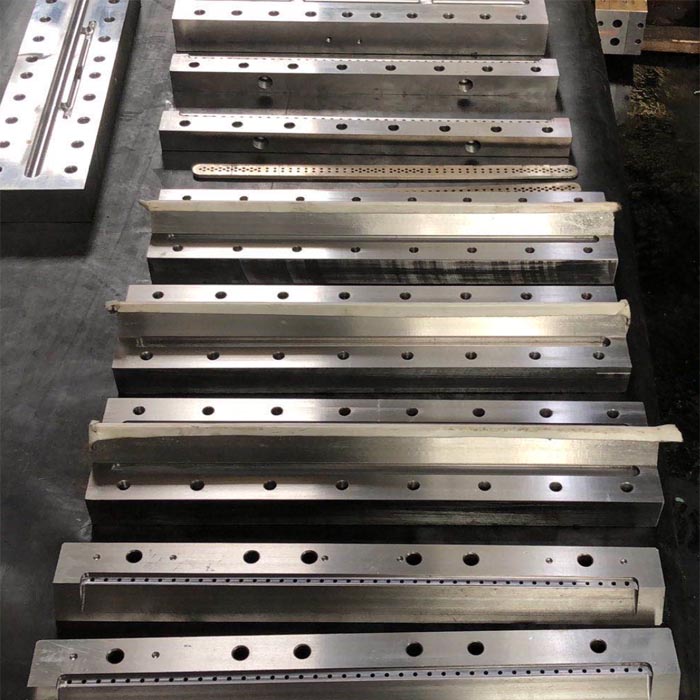

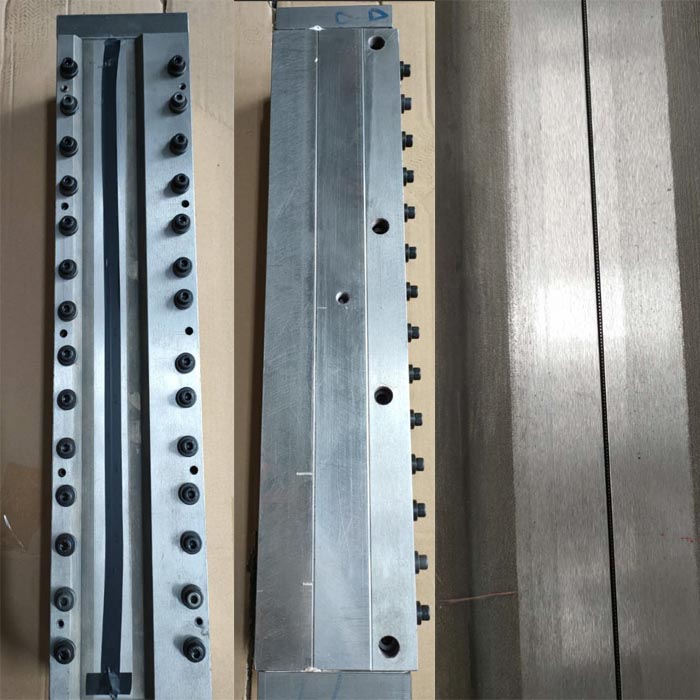

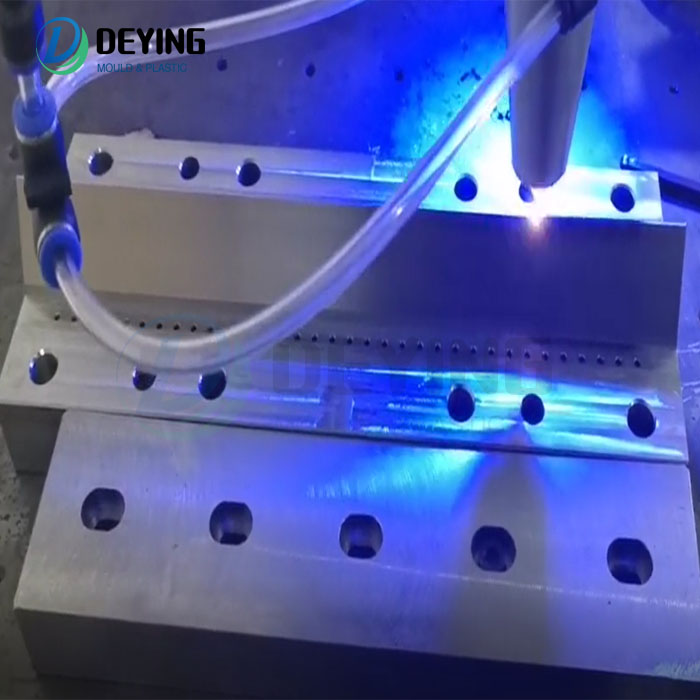

The core technology is the small nozzle on the spinneret. This nozzle is not only small in size,only 0.15mm, but also has a complex hole pattern on such a small nozzle, which is extremely difficult to process, and the nozzle processing process requires Several months. If the

processing accuracy is not high, the final meltblown cloth produced will not meet the corresponding technical requirements, which w川 affect the protective performance of the mask .

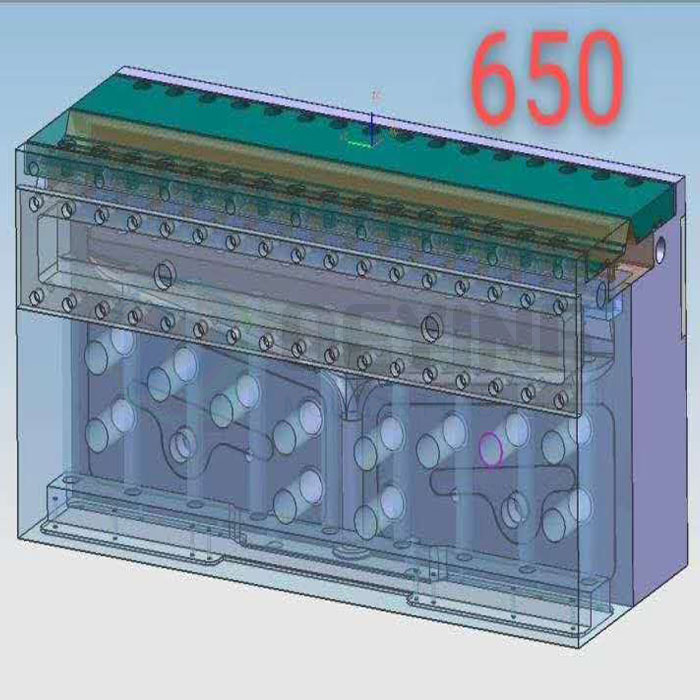

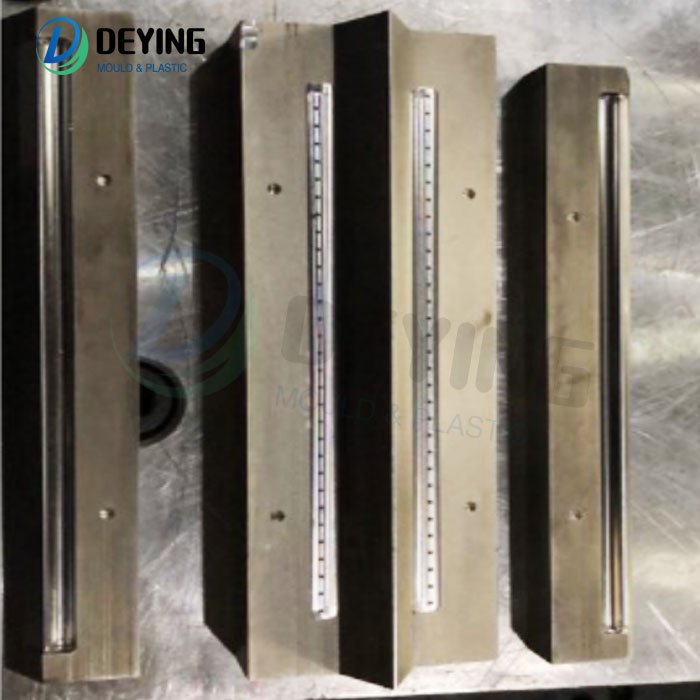

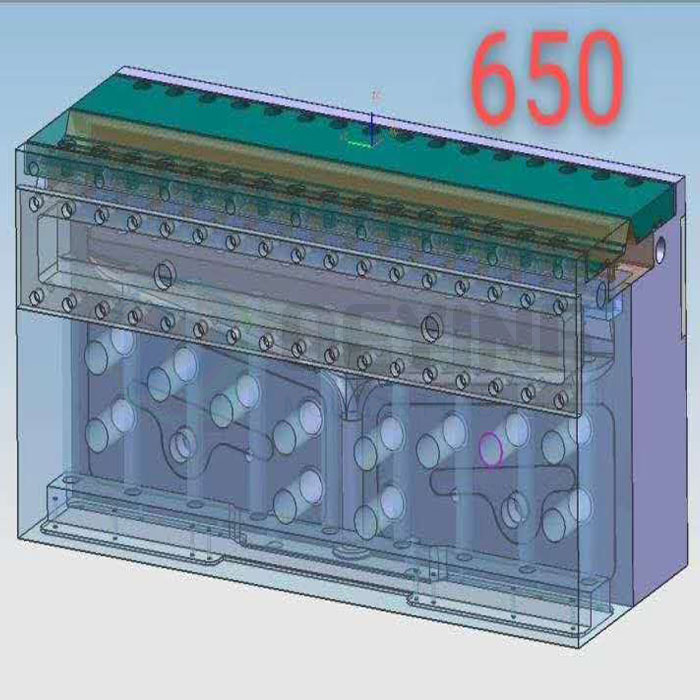

The structure of the spinneret is divided into three forms according to the shape of the spinneret, round, fan and rectangular. At present, circular plates and rectangular plates are used more at home and abroad. In order to be suitable for different kinds of chemical fiber spinning occasions, round spinnerets are divided into flat plate type, flange plate type, plate ring, flange ring, etc.: rectangular spinneret is divided into flange rectangle and flange groove rectangle, etc., It is mostly used for short fiber spinning with more holes.

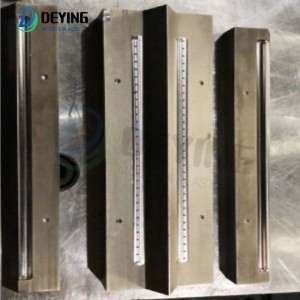

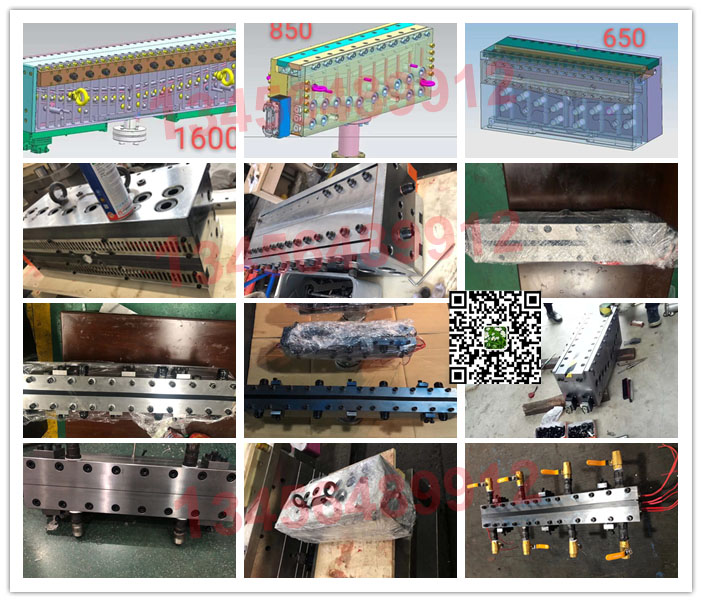

Melt blown spinneret size:

Length 300mm and 450mm,650mm,850mm are available

Feeding hole: drilled with 0.2mm diameter electrode tube , finished diameter during 0.25-0.26mm.

Melt-blown nonwoven fabric is made by entangling fibers while extruded material from the spinneret in the same time blowing hot air. The common application is face masks, industrial filters, etc.

Infect by CORNA-19 epidemic, masks are very limited, no matter the FFP3, FFP2, N95, KN95 KN90, surgical mask; medical mask, ordinary masks/respirator, all masks are lack.

Mask making machines are working every day every 24 hours, the consumables and spare parts in stock are very necessary to keep the machine running.

Polypropylene materials are extracted from petroleum. Currently, Sinopec and other companies can produce them in large quantities, but the equipment that produces polypropylene as melt blown cloth, especially the core components and spinnerets, mainly depends on imports. These suppliers mainly include Japan's Kasen spinneret, German Enka, and Japanese spinneret. Japanese suppliers occupy the most important position. With the current output of several companies, it is far from satisfying the market demand.

Therefore, the production capacity of masks ultimately depends on the output of the melt blown cloth production equipment, and the core spinneret nozzle of the melt blown cloth production equipment is very difficult to produce. The processing time takes several months, and the output cannot be greatly increased in a short time. And the production capacity is very limited, which also makes the mask production can only maximize the use of current equipment and increase production by extending the working time of the production line.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com