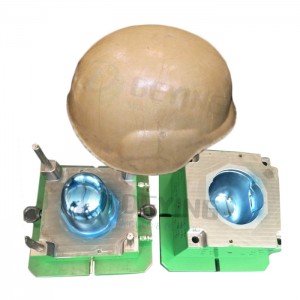

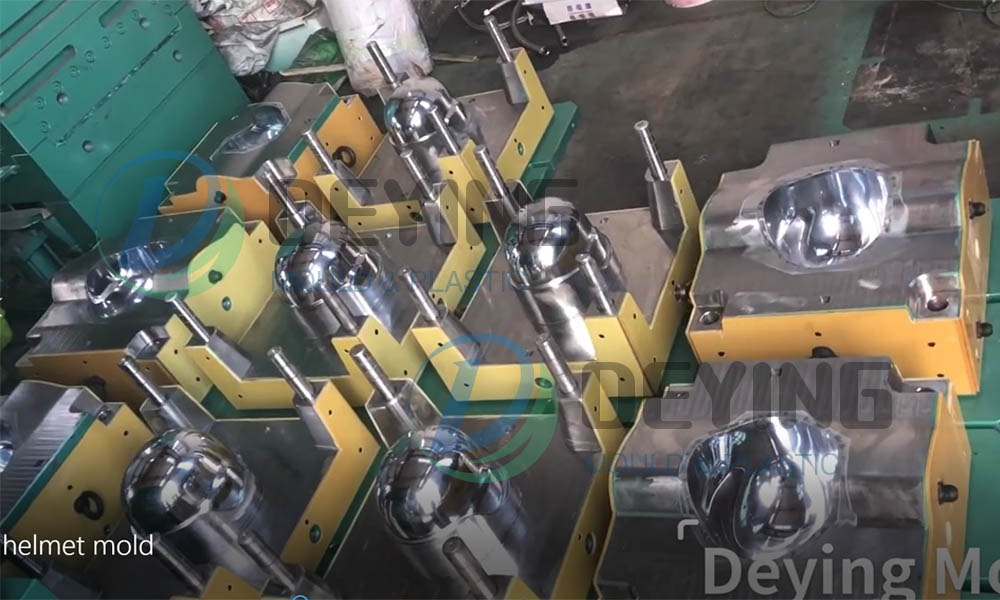

Professional Tactical Bulletproof Helmet mold manufacturer, the world's best quality mold manufacturer in Taizhou.

Mold maintenance is more important than mold repair. The more the mold is repaired, the shorter its lifespan. The better the mold is maintained, the longer its lifespan will be. Mold maintenance is mainly divided into three points;

1. Daily maintenance of the mold: refueling of various moving parts such as thimble, row position, guide post, guide sleeve,

The cleaning of the mold surface and the drainage of water are the daily maintenance during mold production.

2. Regular maintenance: Regular maintenance includes the cleaning of the exhaust slot in addition to the daily maintenance, the air trapping and the black level and the exhaust, and the correction of damage and wear parts.

3. Appearance maintenance: Paint the outside of the mold base to avoid rust. When lowering the mold, the fixed mold and the movable mold should be coated with anti-rust oil. The mold should be closed tightly to prevent dust from entering the cavity.

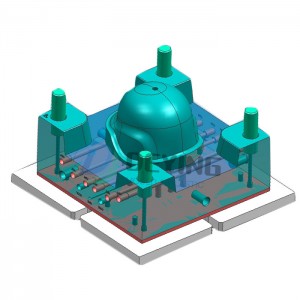

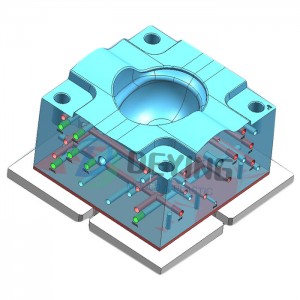

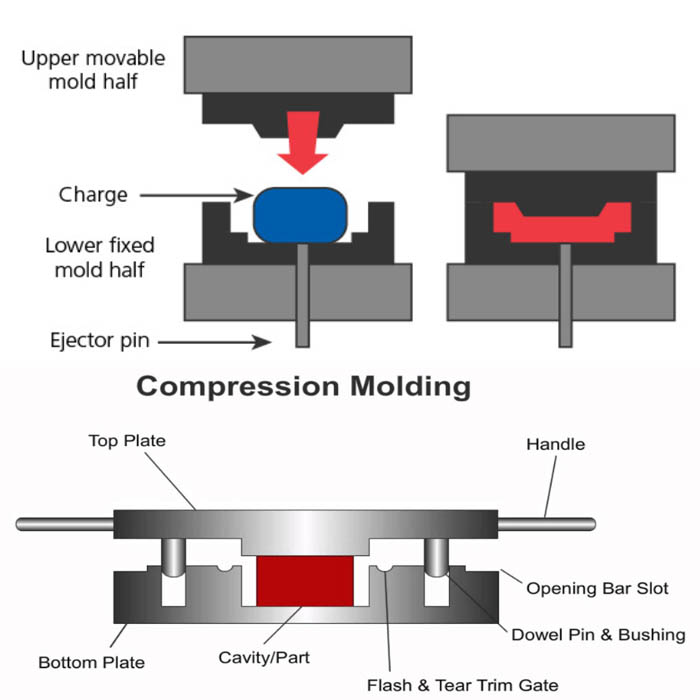

Compression molding is a method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while heat and pressure are maintained until the molding material has cured.

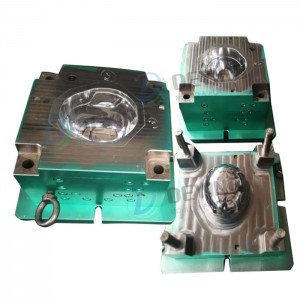

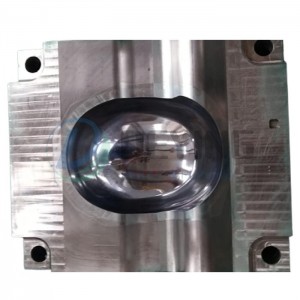

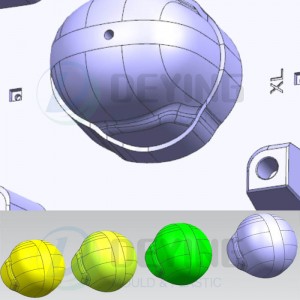

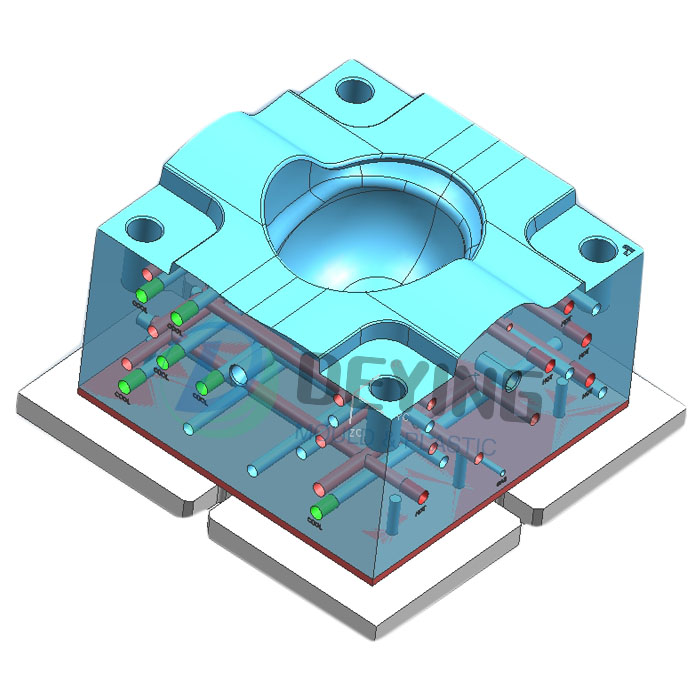

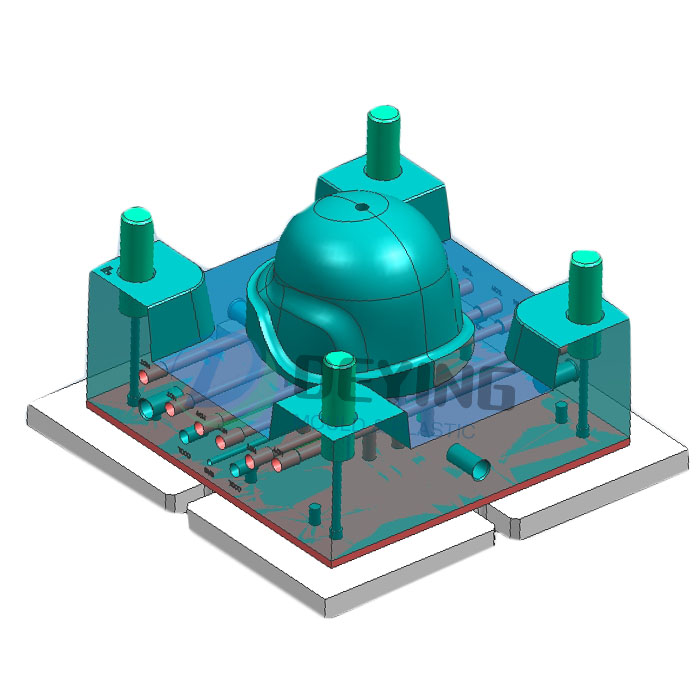

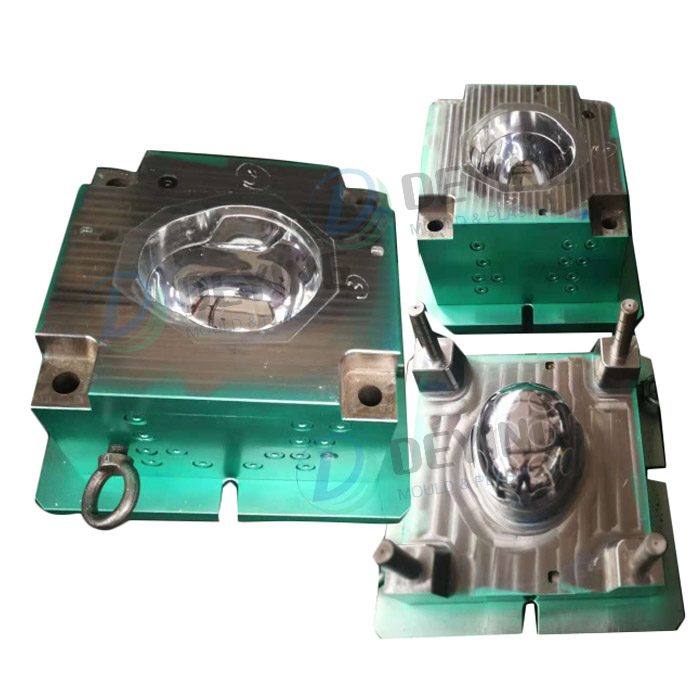

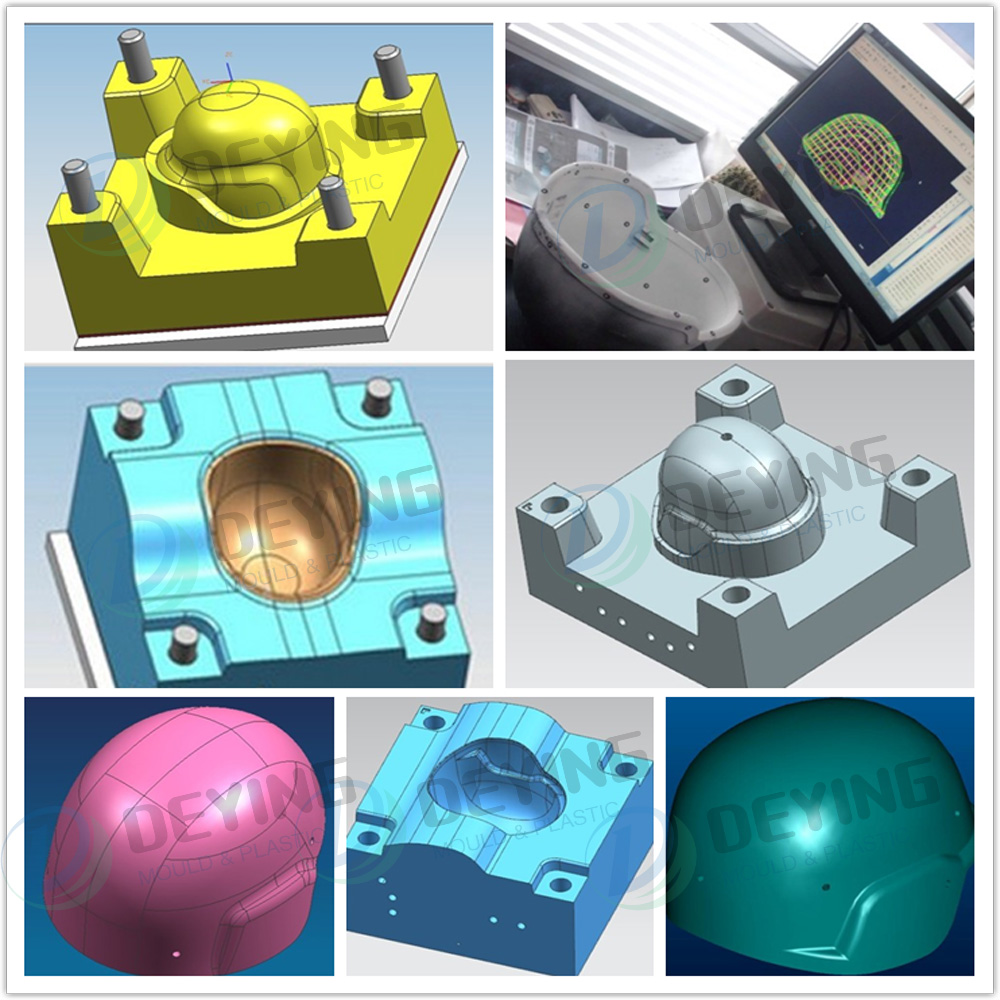

UD/KEVLAR product mould

UHMWPE is commonly known as very high molecular weight polyethylene. Its molecular weight can reach 1 to 5 million. It has high wear resistance, low friction coefficient, high impact resistance, and better sound-absorbing performance. Compared with ordinary thermoplastics, it has lower fluidity and is difficult to process. At present, it can only be produced by molding. Our company cooperated with the *** unit, using its good impact resistance, developed the body armor and bulletproof helmet molds, realized segmented pressurization and heating on a pair of molds, and switched the heating mold to cooling in the later stage of molding. The mold ensures that the product is cooled and shaped to the set temperature and set material hardness, ensuring that the product can be easily taken out of the mold.

MB/Wechat/Whatsapp:+0086-13456489912

sophiemould@foxmail.com